Stainless steel pipe rolling oil removal device

A stainless steel pipe and rolling oil technology, applied in the field of stainless steel, can solve the problems of long draining time, failure to reach, oil pollution on the rolling site, etc., to achieve the effects of avoiding pollution, speeding up the accumulation speed, and improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

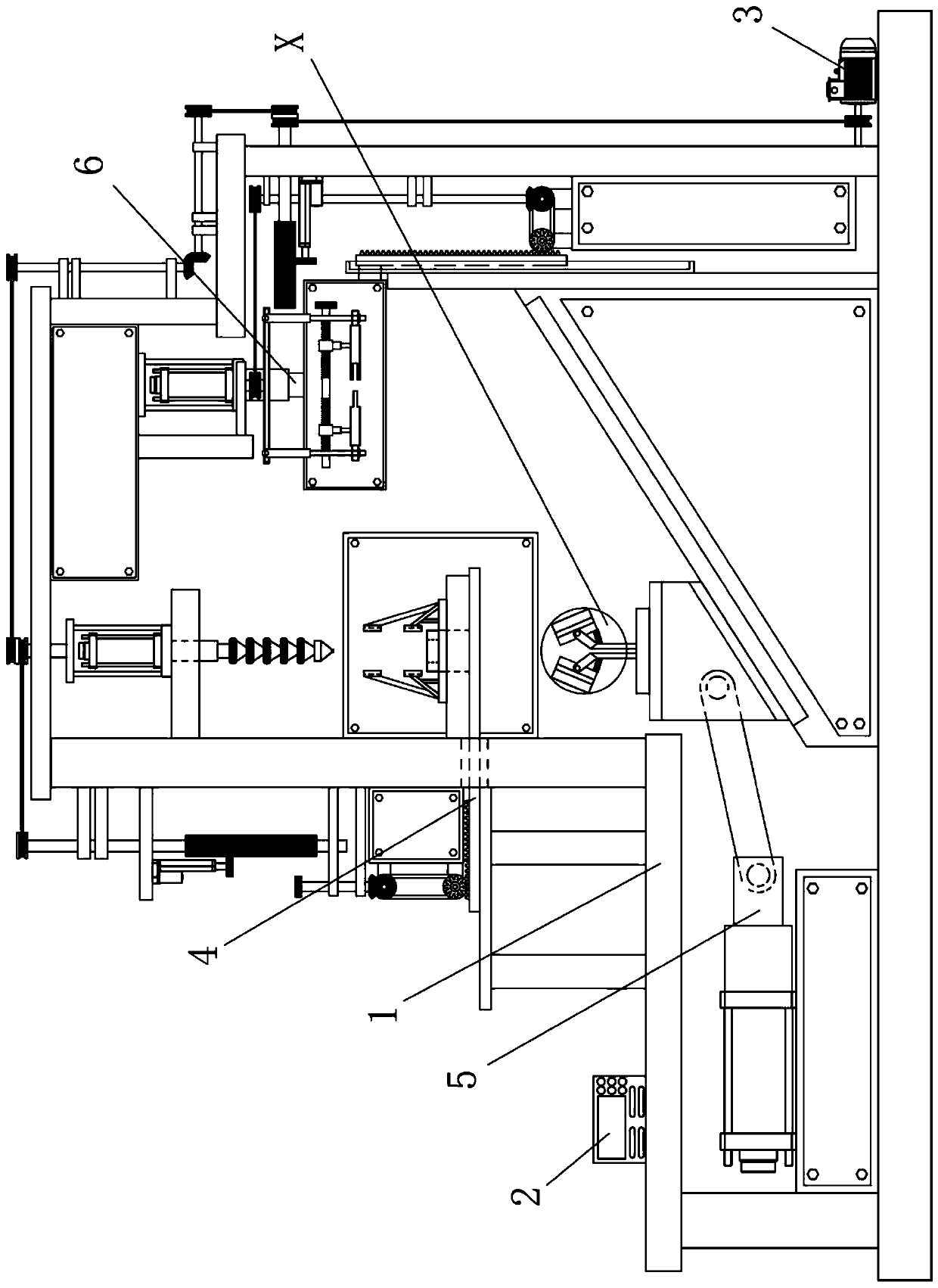

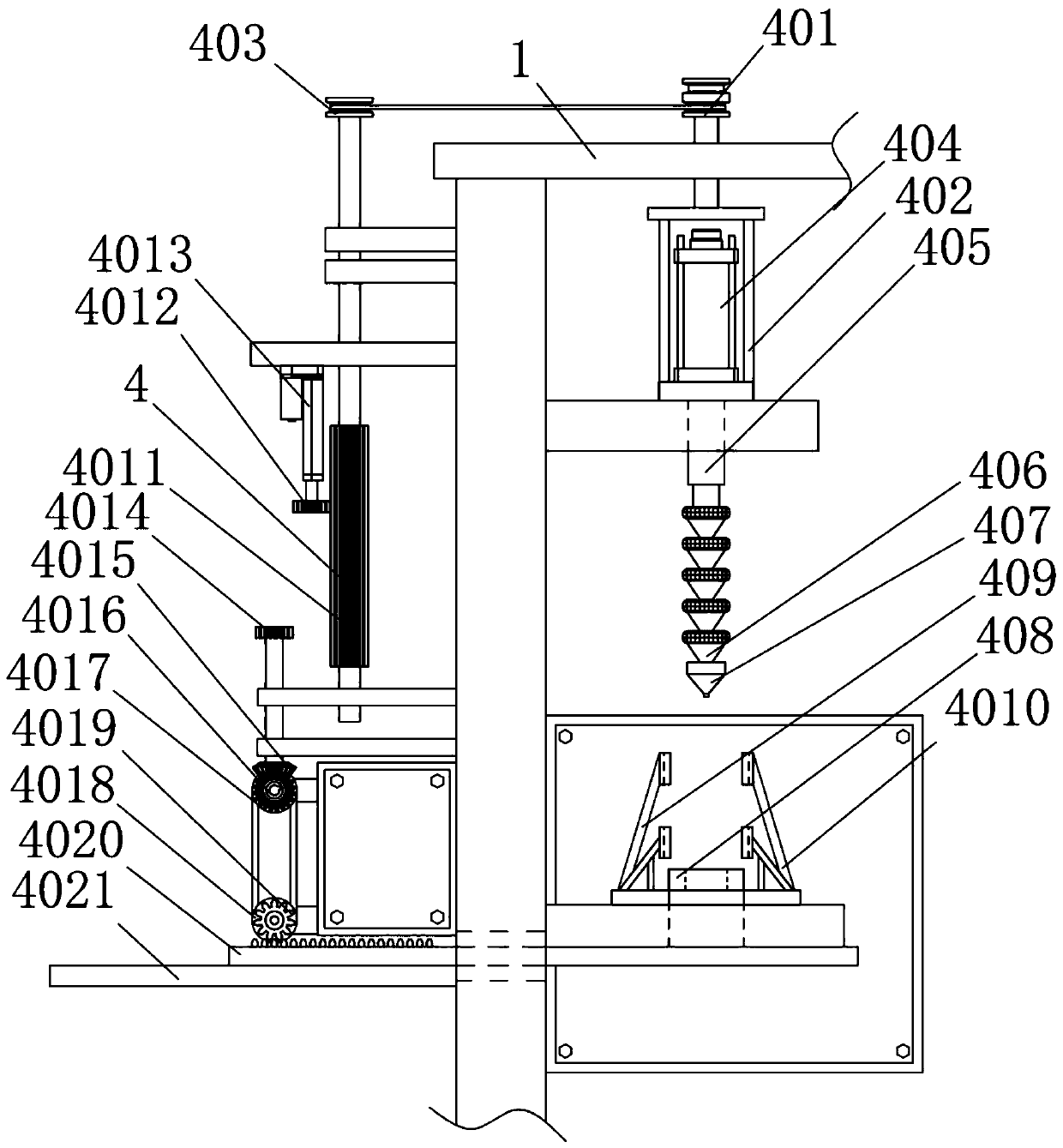

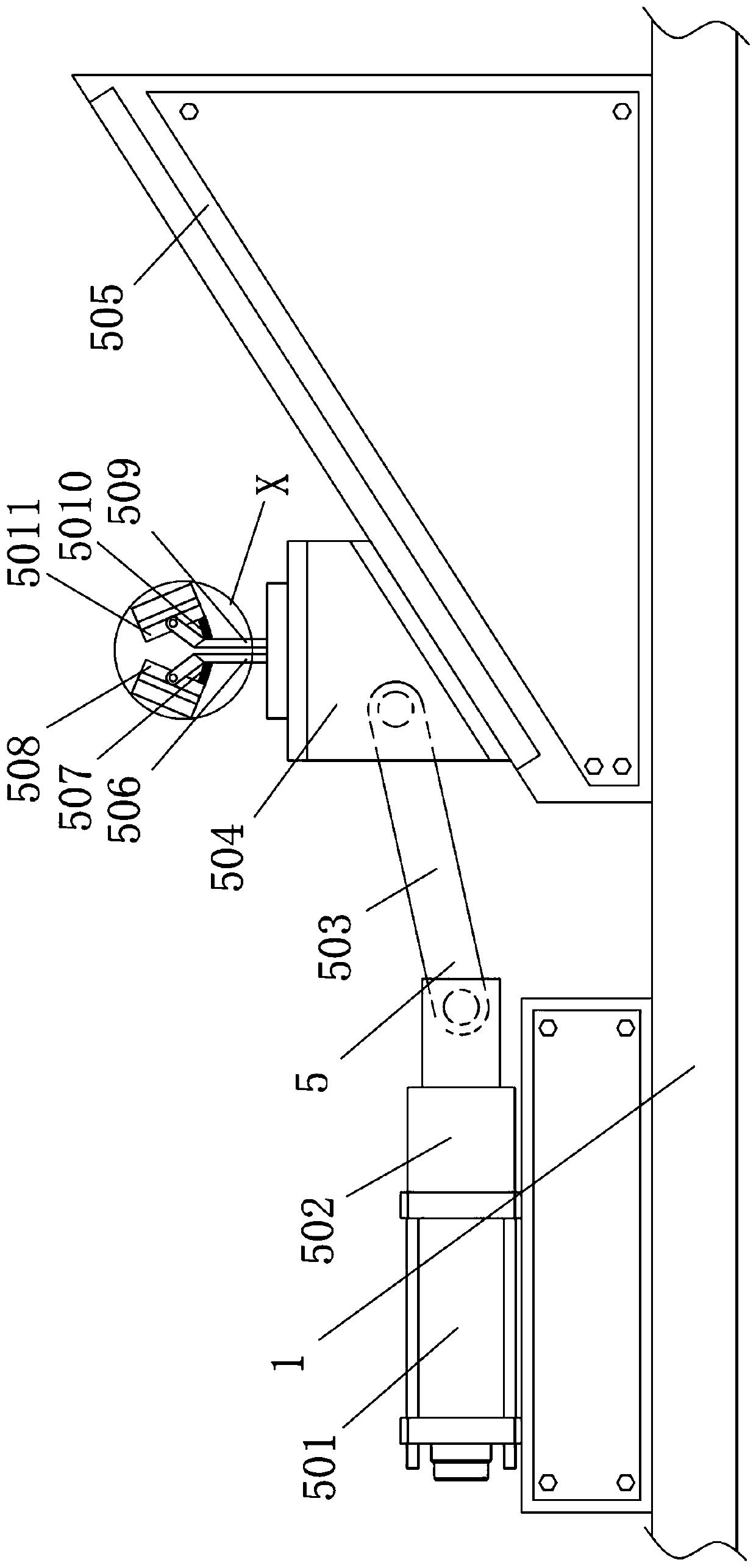

[0028] A stainless steel pipe rolling oil removal device, such as Figure 1-8 As shown, it includes a support frame 1, a control panel 2, a motor 3, an inner wall degreasing mechanism 4, a transfer mechanism 5 and an outer wall degreasing mechanism 6; the top left part of the support frame 1 is provided with a control panel 2; A motor 3 is provided at the top of the support frame 1; an inner wall degreasing mechanism 4 is provided at the top of the left end of the support frame 1 and an inner left end top; a transfer mechanism 5 is provided at the inner bottom of the support frame 1; And the bottom of the right end of the outer wall degreasing mechanism 6 is connected with the motor 3 , and the top of the left end of the outer wall degreasing mechanism 6 is connected with the inner wall degreasing mechanism 4 .

[0029] When in use, place the device horizontally at the position to be used through the support frame 1, turn on the power, deploy the device through the control pan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com