A v-method molding production line

A production line and connecting plate technology, which is applied to casting molding equipment, cores, casting molds, etc., can solve the problems of high production line cost, wide area occupation, and large engineering volume, so as to increase labor intensity, realize automation, and structure novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

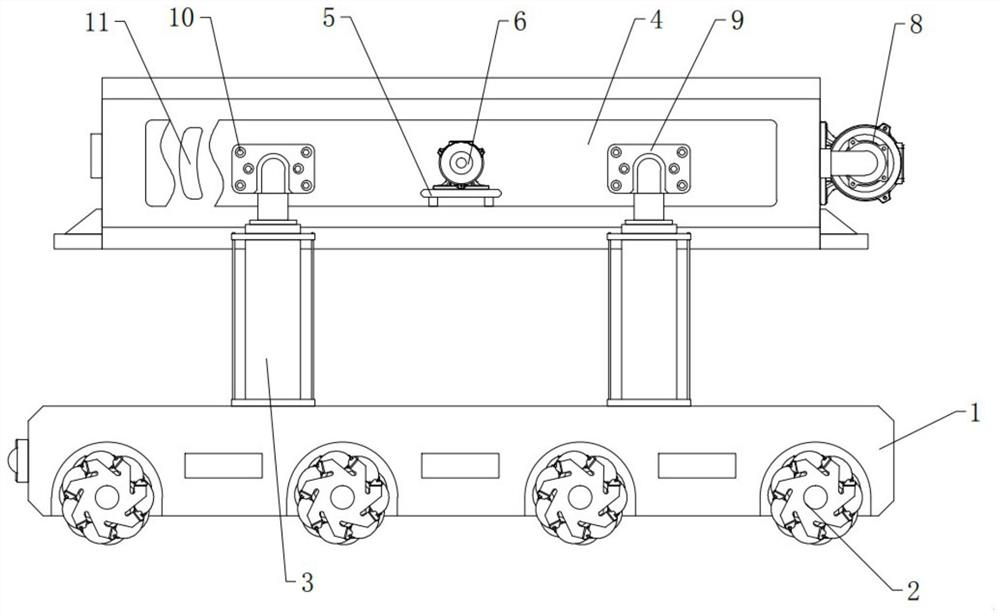

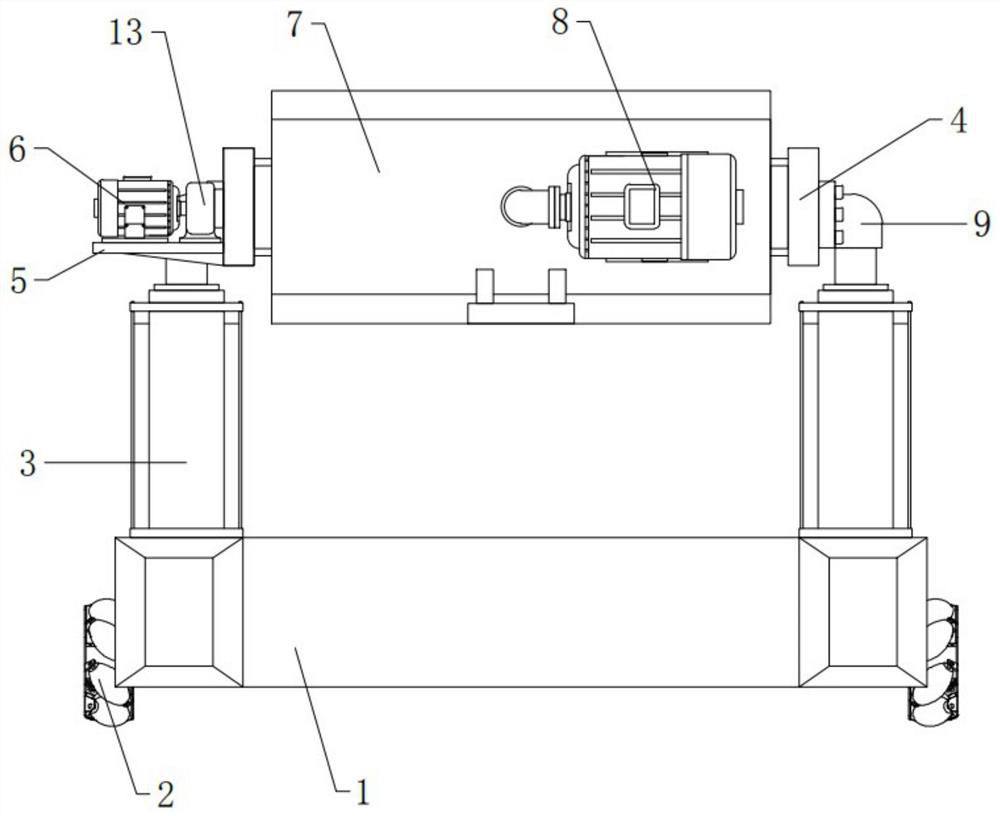

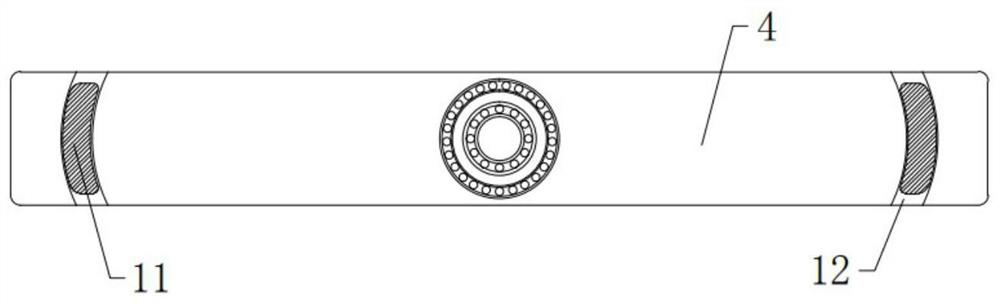

[0026] Embodiment: the present invention provides a kind of technical scheme: according to the description attached Figure 1-4 It can be seen that this case is a V-method molding production line, which mainly includes: base 1, connecting plate 4, base 5, servo motor 6, mold box 7, vacuum pump 8, connecting components, supporting components, multiple driving wheels 2 and multiple Hydraulic rod 3, the connection relationship is as follows:

[0027] A plurality of driving wheels 2 are fixedly installed on the base 1, and the plurality of driving wheels 2 are evenly distributed on both sides of the base 1, and a plurality of hydraulic rods 3 are fixedly installed on the top of the base 1, and a plurality of hydraulic rods 3 are evenly distributed on the On both sides of the base 1, the connecting plate 4 is fixedly installed on the telescopic end of the hydraulic rod 3, the connecting assembly is fixedly installed on the connection between the connecting plate 4 and the hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com