A kind of equipment and method of multi-nozzle injection composite roll

A composite roll and multi-nozzle technology, applied in the field of roll spray forming, can solve the problems of high stress, roughness and damage of the blank, and achieve the effects of improving strength and wear resistance, improving service life and improving compounding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

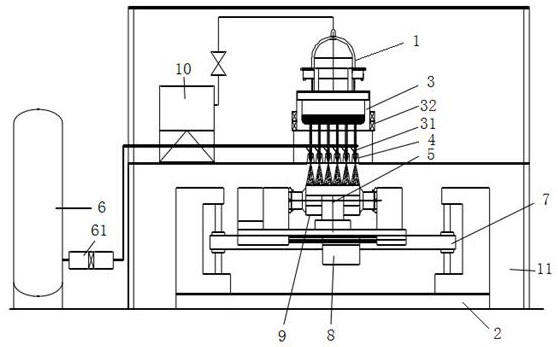

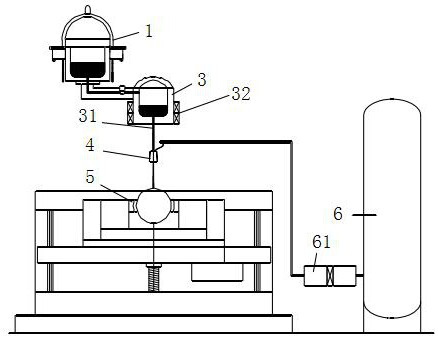

[0037] Such as figure 1 and figure 2 Shown: a multi-nozzle injection compound roll equipment, including vacuum melting furnace 1, frame 2, tundish 3, multiple nozzles 4, friction heating device 5, inert gas tank 6 and automatic control system. Wherein, the vacuum smelting furnace 1 is connected to the tundish 3, and the below of the tundish 3 is provided with a plurality of nozzles 4, and each nozzle 4 is connected to the tundish 3 by a liquid conduit 31, and the number of the liquid conduit 31 is the same as that of the tundish 3. The number of nozzles 4 is corresponding; the bottom of the nozzles 4 is provided with the frame 2, and the frame 2 is provided with a lifting mechanism 7 for driving the blank to move up and down and a rotating mechanism 8 for driving the blank to swing or rotate. The heating device 5 is arranged toward...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com