An Acceleration Pump for Particle Transport in Thermonuclear Fusion Solid State Pebble Beds

A thermonuclear fusion and acceleration pump technology, which is applied in the direction of conveyors, transportation and packaging, and conveying bulk materials, can solve the problems of particle flow blockage, etc., and achieve the effects of reducing friction, increasing filling rate, and reducing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

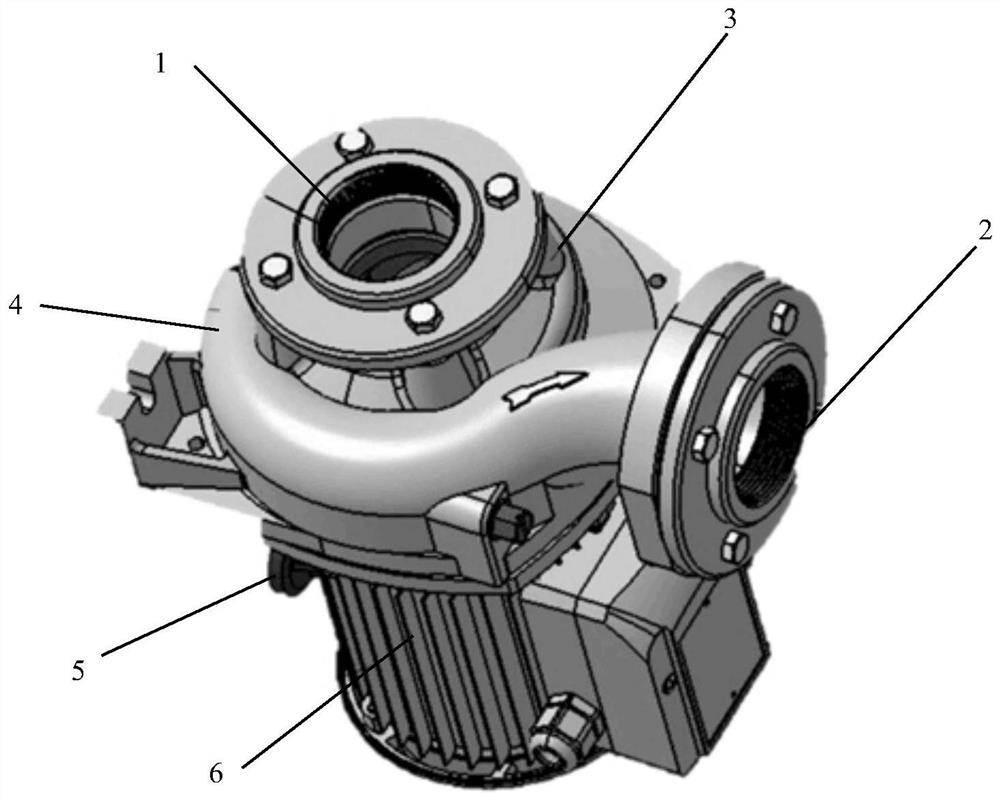

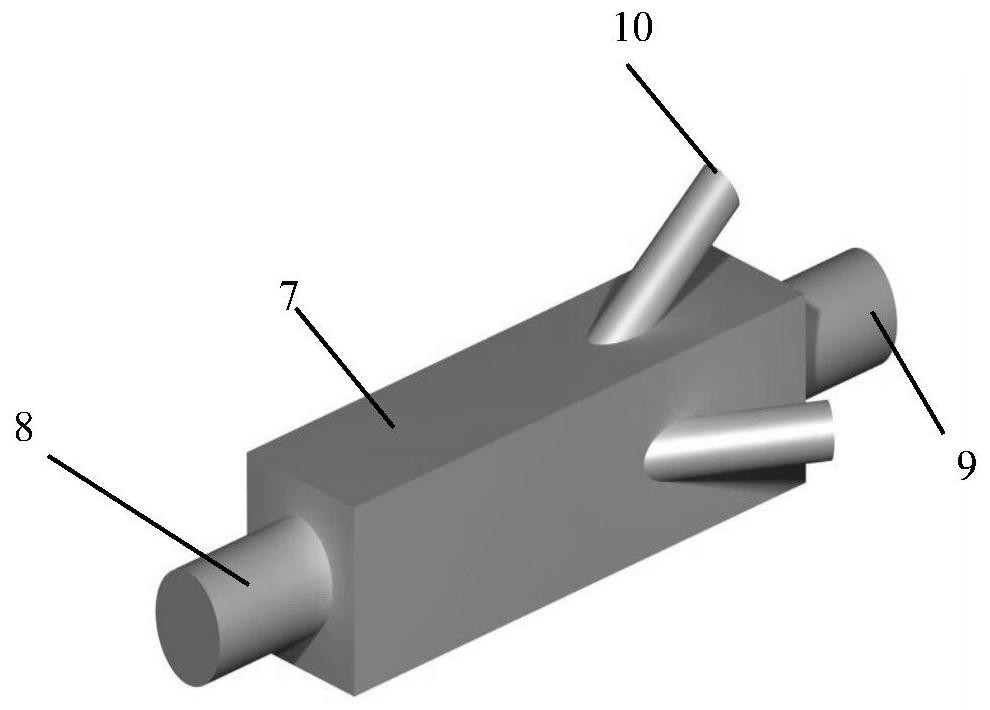

[0021] Such as Figure 1-2 As shown, the main body design of the pump includes: particle inflow inlet 1, particle outflow outlet 2, cover surface 3, particle outflow outlet pipe 4, helium gas vent 5, rotating motor 6, speed regulation chamber 7, particle flow regulation chamber Inlet 8, particle outflow port 9, reverse ventilation port 10 in the regulating chamber. The particles enter the pump body from the particle inflow port 1, and are accelerated by the spiral blades in the pump body. The high-speed particles leave the pump body from the particle outflow port 2. The chamber 7 is designed with four reverse ventilation ports 10, through which the helium gas is introduced so that the particle flow is properly decelerated, thereby increasing the filling rate of the particles.

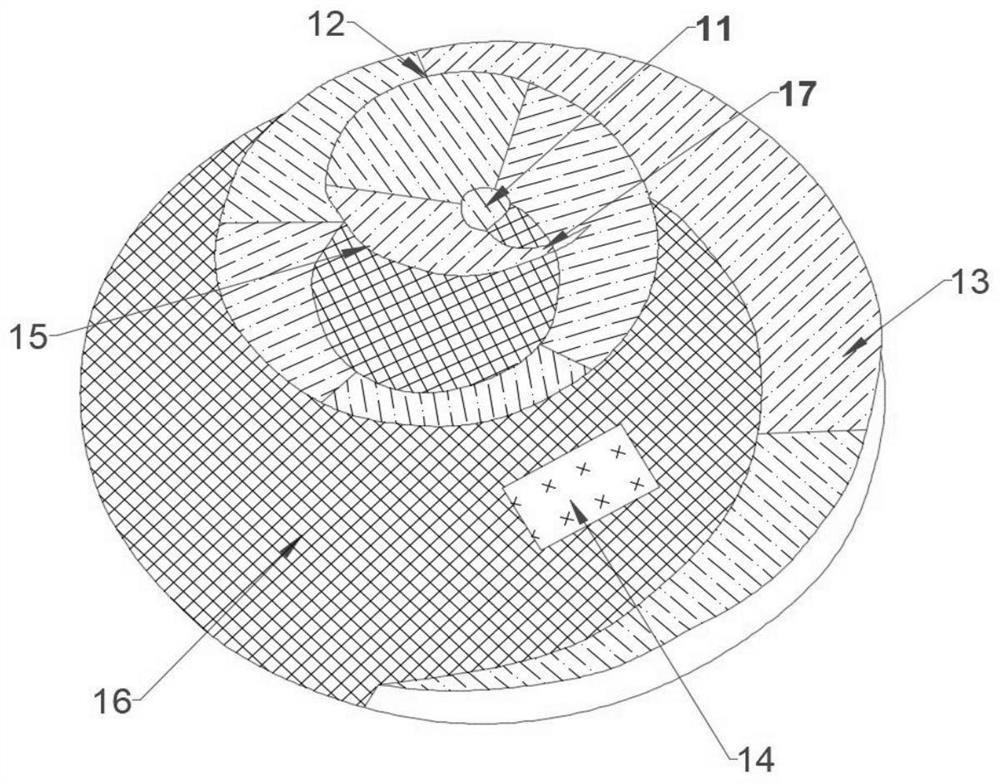

[0022] Such as image 3 As shown, the three-dimensional helical blade design of the pump: hub end surface 11, rim surface 12, impeller suction surface 13, pore opening surface 14, impeller pressure su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com