Preparation method of composite material with negative dielectric constant and negative permeability metamaterial performance

A technology of composite materials and metamaterials, which is applied in the field of preparation of carbon nanotube/polyolefin elastomer composite materials, can solve the problems of limited application, matching of negative permittivity and magnetic permeability, etc., and achieves simple and convenient preparation methods and expanded The effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

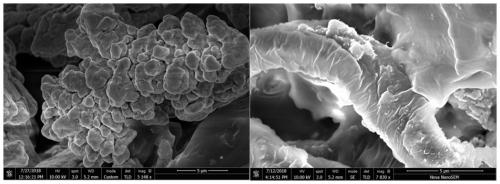

Image

Examples

preparation example Construction

[0028] A method for preparing a composite material with double negative metamaterial properties, the following method steps can be used:

[0029] 1. Swelling polyolefin elastomer (POE): weigh POE 0.1-0.5g, weigh a certain amount of organic solvent, you can choose one of toluene, acetone, and n-hexane, and the mass ratio of POE to organic solvent is 1:3 , Grind the two uniformly and let stand at 25°C for 10-40min to make POE swell.

[0030] 2. Preparation of carbon nanotube (CNT) / polyolefin elastomer composite material: Weigh 0.01-0.1g CNT, fully grind it with swollen POE, and then dry it in an oven at 30-40°C to remove the solvent.

[0031] 3. Preparation of carbon nanotube / polyolefin elastomer metamaterial block: Weigh 0.5-1.5g of conductive silver glue, mix with powdered CNT / POE composite material particles, and then under 1.0-10.0MPa in PTFE Curing in an vinyl mold for 2-18 hours to prepare a composite material with double-negative metamaterial properties.

[0032] The fo...

Embodiment 1

[0034] This embodiment is a method for preparing a carbon nanotube / polyolefin elastomer composite material with metamaterial properties, which is carried out according to the following steps:

[0035] Swelling polyolefin elastomer (POE): Weigh 0.288g of POE, weigh toluene as an organic solvent, the mass ratio of POE to organic solvent is 1:3, grind both uniformly and let stand at 25°C for 10min to make POE swell .

[0036] Preparation of carbon nanotube (CNT) / polyolefin elastomer composite material: Weigh 0.012g of CNT, fully grind it with swollen POE, and then dry it in an oven at 30°C to remove the solvent.

[0037] Preparation of carbon nanotube / polyolefin elastomer metamaterial block: Weigh 1.5g of conductive silver glue, mix it with powdered CNT / POE composite material particles, and then solidify and form it in a polytetrafluoroethylene mold under a certain pressure.

[0038] In the present invention, CNT is evenly attached to the POE surface in a swelling manner, and a ...

Embodiment 2

[0041] This embodiment is a method for preparing a carbon nanotube / polyolefin elastomer composite material with metamaterial properties, which is carried out according to the following steps:

[0042] Swelling polyolefin elastomer (POE): Weigh 0.282g of POE, weigh acetone as an organic solvent, and the mass ratio of POE to organic solvent is 1:3. Grind both uniformly and let stand at 25°C for 20 minutes to make POE swell .

[0043] Preparation of carbon nanotube (CNT) / polyolefin elastomer composite material: Weigh 0.018g of CNT, fully grind it with swollen POE, and then dry it in an oven at 40°C to remove the solvent.

[0044]Preparation of carbon nanotube / polyolefin elastomer metamaterial block: Weigh 1.5g of conductive silver glue, mix it with powdered CNT / POE composite material particles, and then solidify and form it in a polytetrafluoroethylene mold under a certain pressure.

[0045] In the present invention, CNT is evenly attached to the POE surface in a swelling manner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com