Method for improving separation efficiency of sludge gravity concentration tank and sludge gravity concentration tank

A sludge thickening tank and gravity thickening technology, which is applied in water/sludge/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of low coagulant utilization efficiency, poor sludge concentration effect, and Sludge activity and other problems, to achieve the effect of enhancing the coagulation reaction, reducing the concentration time, and reducing the amount of chemicals used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

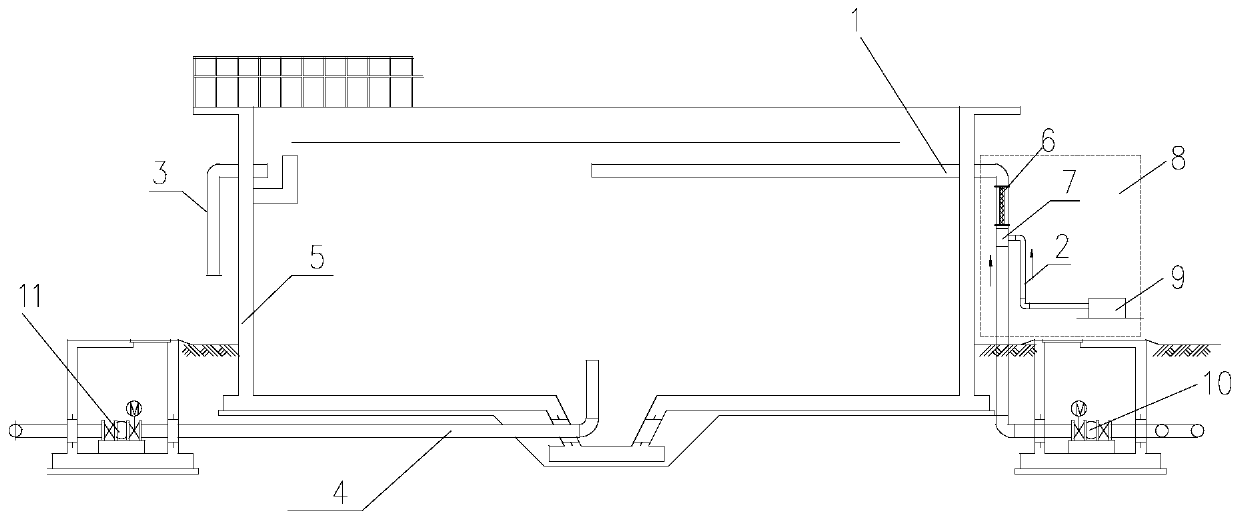

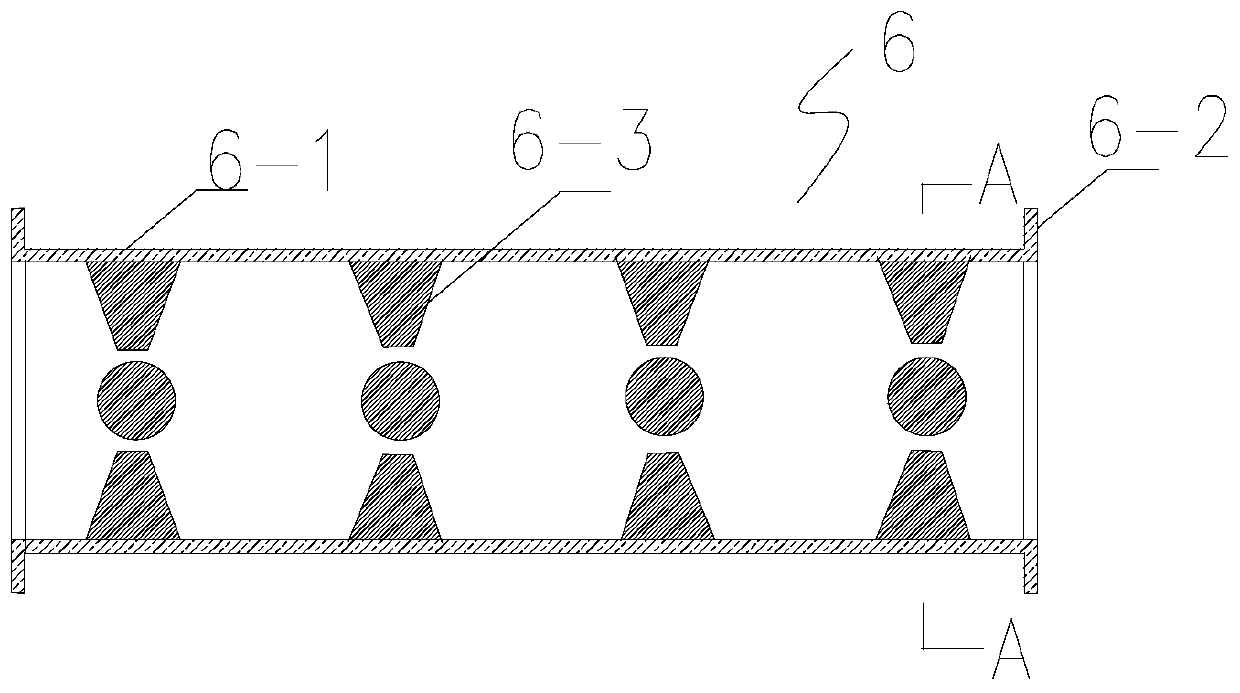

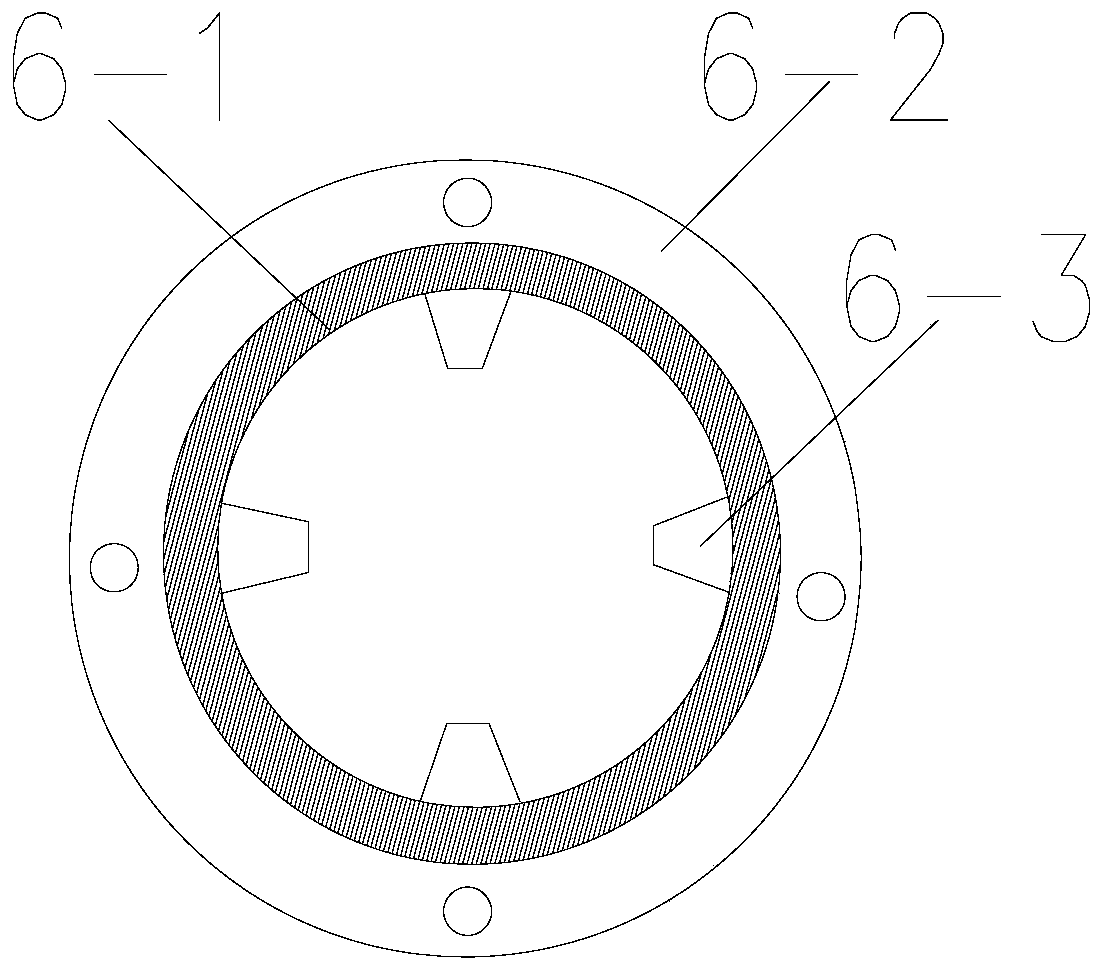

[0025] Below in conjunction with preferred embodiment, the specific implementation mode provided according to the present invention is described in detail as follows:

[0026] See the accompanying drawings for details. This embodiment provides a method to improve the separation efficiency of the sludge gravity concentration tank. Through the optimized coagulant dosing position and the method of setting the spoiler in the pipeline mixer, the coagulant in the tank can be increased. The contact time with sludge can improve the utilization rate of coagulant, enhance the effect of coagulation reaction and reduce the effect of coagulant dosage. The specific steps are as follows:

[0027] 1) In the body of the sludge thickening tank with a circular shape, the sludge inlet pipe is placed on the upper side wall of the sludge thickening tank body, the mud inlet pipe is connected with the coagulant dosing device, and the sludge lifting pump sends the sludge into the inlet mud pipe;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com