A biological reduction treatment technology for bulky sludge

A technology for bulking sludge and sludge, applied in the field of environmental pollution control, can solve the problems of difficult dehydration, high water content, poor sedimentation, etc., and achieve the effects of simple and convenient operation, improved dehydration performance, and strong affinity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1: Demonstration of the effect of treating bulk sludge produced by a petrochemical PTA enterprise

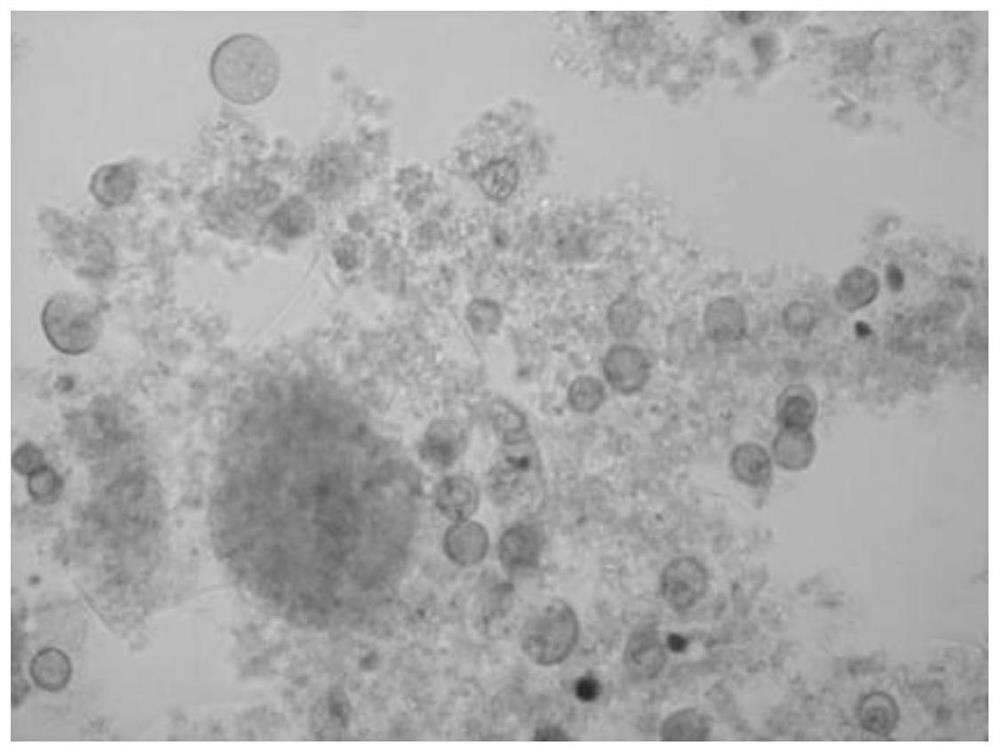

[0056] The excess sludge produced by a company producing PTA after treating sewage is bulky hazardous waste sludge. In the untreated case, the sludge settling ratio was 99%. After 24 hours of standing and settling, the bulked sludge is concentrated, flocculated and filtered by a belt filter press, and the moisture content of the obtained mud cake is still as high as 92%.

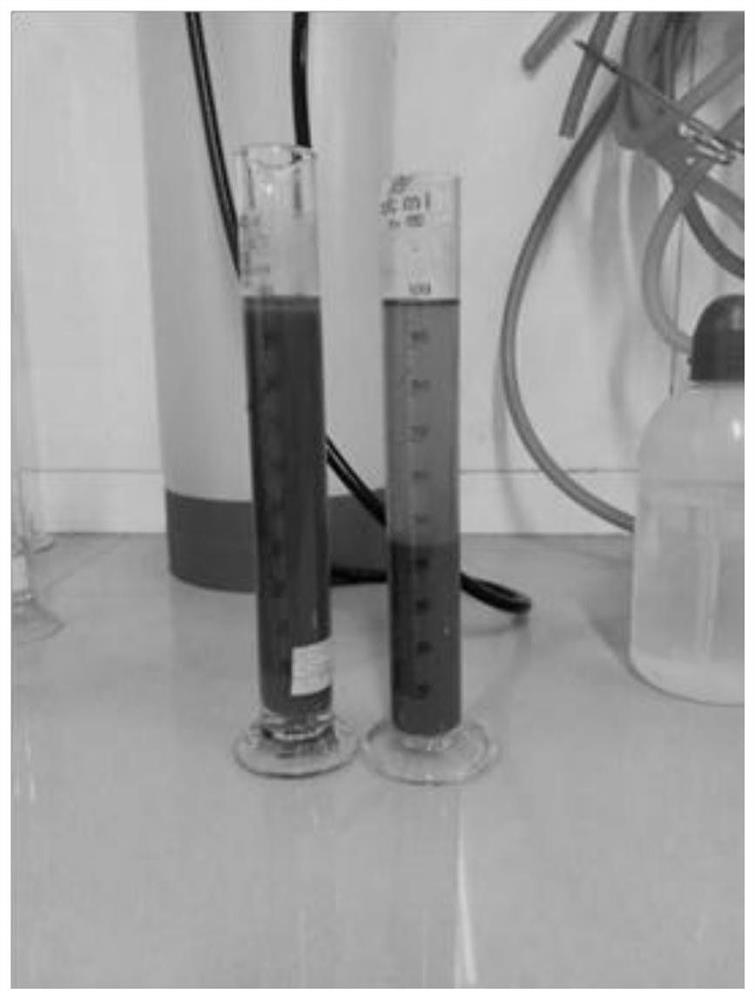

[0057] The composite microbial seed solution optimized by using the bulk sludge to be treated is prepared according to the above method. 5m generated by the above-mentioned PTA manufacturers 3 The bulky excess sludge (water content 99%) was added to the reaction tank, and then 150L of the optimized composite microbial seed solution was added (the volume of the optimized composite microbial seed solution was 3% of the bulk sludge volume), and then 15g / LFeSO 4 ·7H 2 O, after fully mixing, tu...

Embodiment 2

[0059] Example 2: Demonstration of the effect of treating bulk sludge produced by a biopharmaceutical enterprise

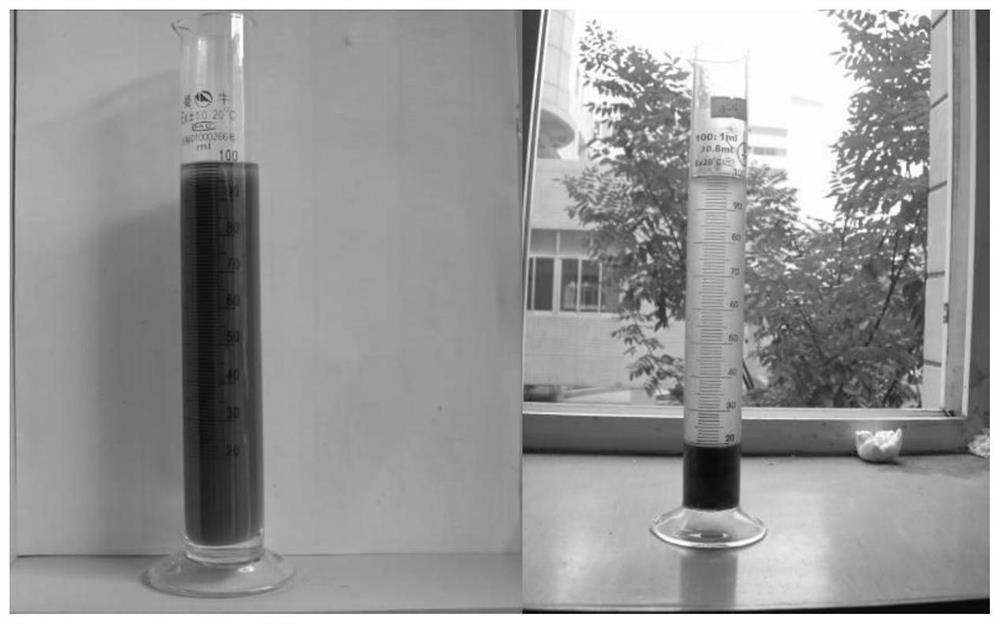

[0060] A biopharmaceutical company mainly produces biopharmaceuticals from human blood. The sedimentation ratio of the sludge liquid after standing in a 100mL graduated cylinder for 24h was used as the test index. In the case of untreated, the sedimentation ratio of bulk sludge produced by the enterprise's sewage treatment is 98-99%. After 24 hours of standing and settling, the bulk sludge is dewatered by a belt filter press, and the moisture content of the obtained mud cake is still as high as 93%, which needs to be treated as hazardous waste.

[0061] The optimized composite microbial seed solution of bulk sludge was prepared according to the above method. 25m generated from the MBR pool of the above-mentioned biopharmaceutical enterprises 3 The bulky excess sludge (with a moisture content of 98%) was put into the sludge biological treatment tank, and then 35...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sedimentation rate | aaaaa | aaaaa |

| sedimentation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com