A kind of wool processing system and processing method

A processing system, wool technology, applied in lighting and heating equipment, drying solid materials without heating, washing/scouring of animal loose hair fibers, etc., can solve the problems of low efficiency, poor effect and high labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

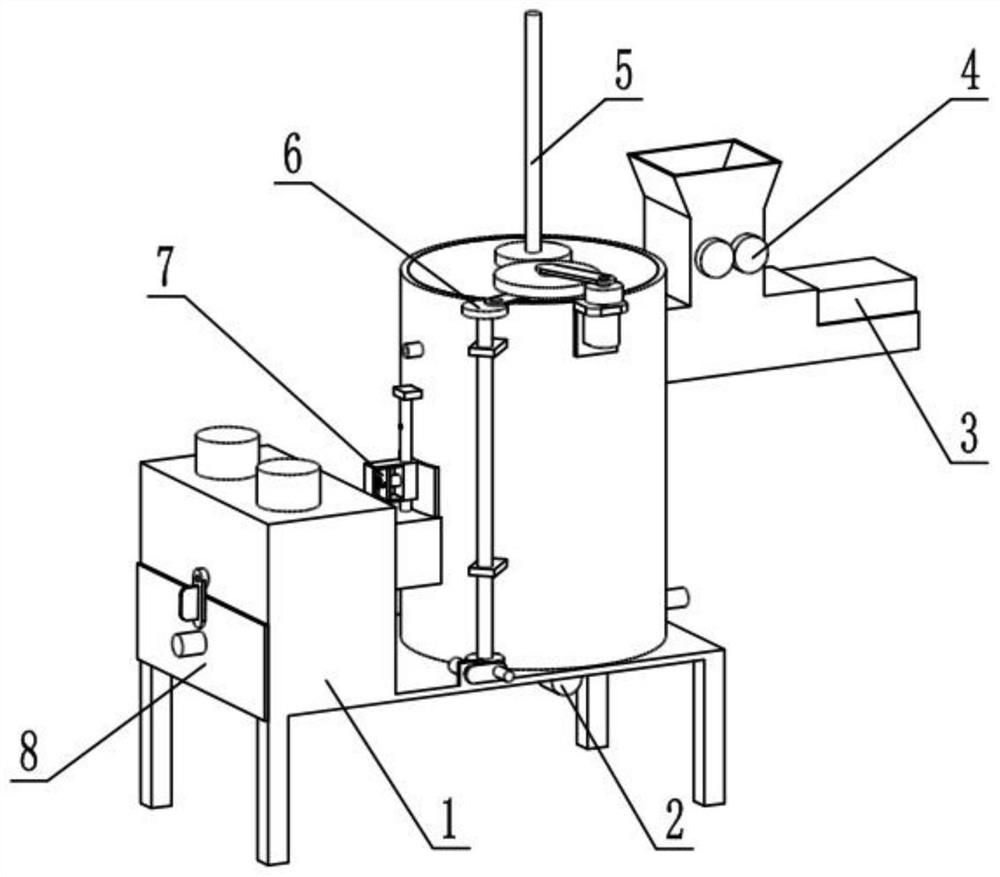

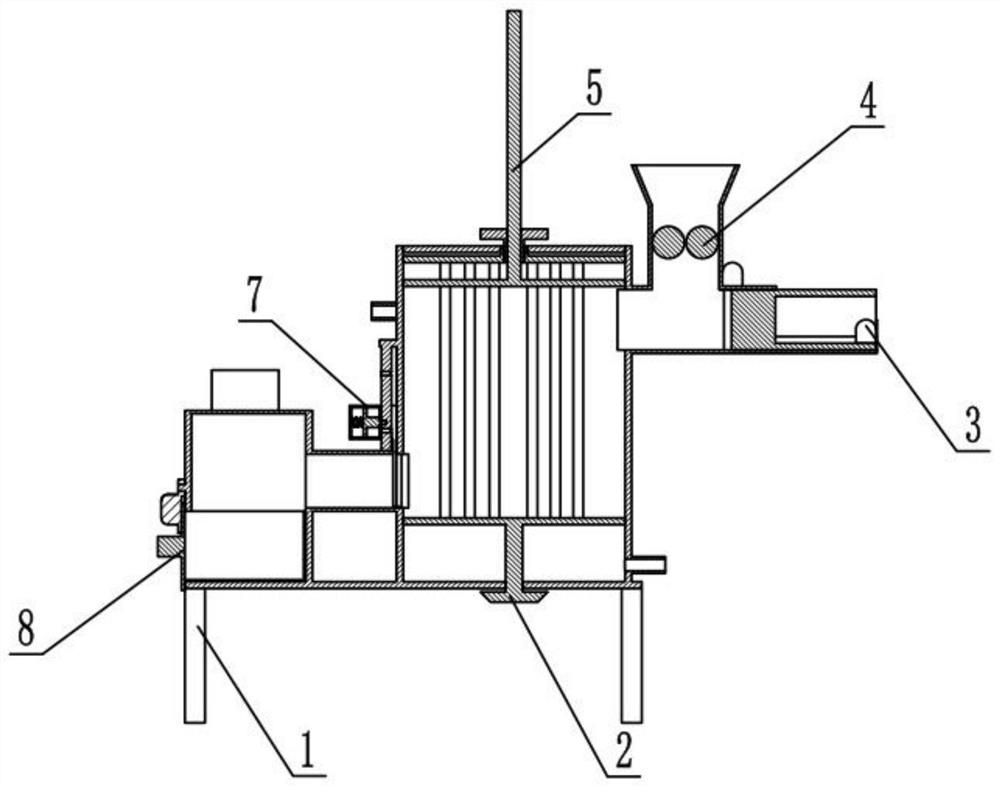

[0035] Such as Figure 1-11 As shown, a wool processing system includes a support frame 1, a stirring mechanism 2, a pushing mechanism 3, a conveying mechanism 4, an extrusion mechanism 5, an extrusion control mechanism 6, a door opening and closing device 7 and a collection device 8. The stirring Mechanism 2 is connected in support frame 1, and described pushing mechanism 3 is slidably connected to the right end of support frame 1, and described delivery mechanism 4 is connected on support frame 1, and delivery mechanism 4 is positioned at the top of push mechanism 3, and described The extruding mechanism 5 is slidably connected to the stirring mechanism 2, the extruding mechanism 5 is rotationally connected with the supporting frame 1, the described extruding control mechanism 6 is connected with the supporting frame 1, and the extruding mechanism 5 is connected with the extruding control mechanism 6 through transmission. The door switch device 7 is slidably connected to the...

specific Embodiment approach 2

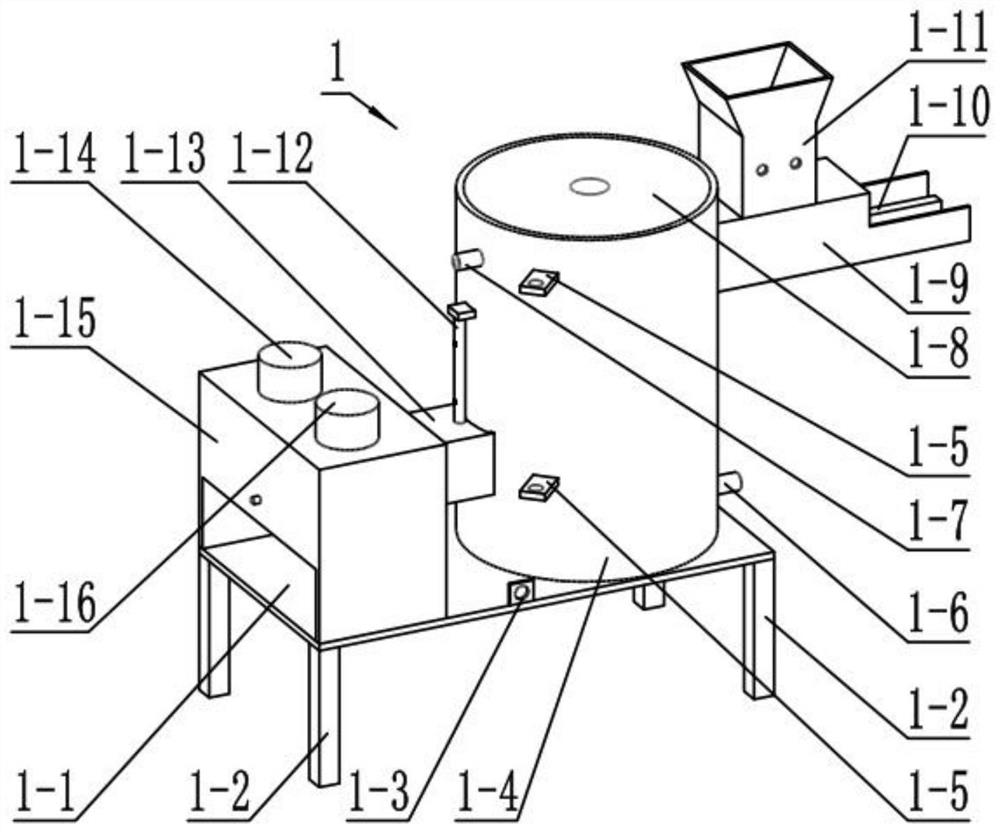

[0038] Such as Figure 1-11 As shown, the support frame 1 includes a main board 1-1, a leg 1-2, a fixed plate I1-3, a fixed pipe 1-4, a fixed plate II1-5, a sewage pipe 1-6, and a liquid inlet pipe 1- 7. Upper cover 1-8, horizontal feeding pipe 1-9, rack 1-10, feeding pipe 1-11, fixed slide bar 1-12, connecting pipe 1-13, exhaust fan 1-14, air exhaust box 1- 15 and blower 1-16, the four corners of the main board 1-1 are all fixedly connected with supporting legs 1-2, the fixed pipe 1-4 is fixedly connected on the right side of the main board 1-1, and the fixed pipe 1-4 is provided with a heating ring , the exhaust box 1-15 is fixedly connected to the left side of the main board 1-1, the left end of the communication pipe 1-13 communicates with the exhaust box 1-15, the right end of the communication pipe 1-13 communicates with the fixed pipe 1-4, and the fixed plate I1 -3 is fixedly connected to the front end of the main board 1-1, two fixed plates Ⅱ 1-5 are provided, and the...

specific Embodiment approach 3

[0041] Such as Figure 1-11 As shown, the stirring mechanism 2 includes a stirring motor 2-1, a stirring gear 2-2, a stirring shaft 2-3, a lower connecting plate 2-4, a stirring column 2-5, an upper connecting plate 2-6 and a connecting circle Set 2-7, the stirring motor 2-1 is fixedly connected to the lower end surface of the main board 1-1, the stirring shaft 2-3 is rotatably connected to the main board 1-1 through a bearing, and the stirring gear 2 is fixedly connected to the lower end of the stirring shaft 2-3 -2, the upper end of the stirring shaft 2-3 is fixedly connected with a lower connecting plate 2-4, and a plurality of stirring columns 2-5 are fixedly connected between the lower connecting plate 2-4 and the upper connecting plate 2-6, and the connecting ring sleeve 2 -7 is fixedly connected to the center of the upper connecting plate 2-6, the connecting ring sleeve 2-7 is rotatably connected to the upper cover 1-8, the stirring motor 2-1 and the stirring gear 2-2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com