Sleeve valve pipe grouting method suitable for deep covering layer permanent curtain

A technology of deep covering layer and sleeve valve tube, which is applied in water conservancy projects, water conservancy engineering equipment, buildings, etc., can solve the water blocking effect of the water blocking curtain, the reliability is not good, it cannot solve the water gushing and sand gushing, and the grouting needs cannot be met, etc. problems, to achieve the effect of easy promotion and application, improved grouting effect and efficiency, and good cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

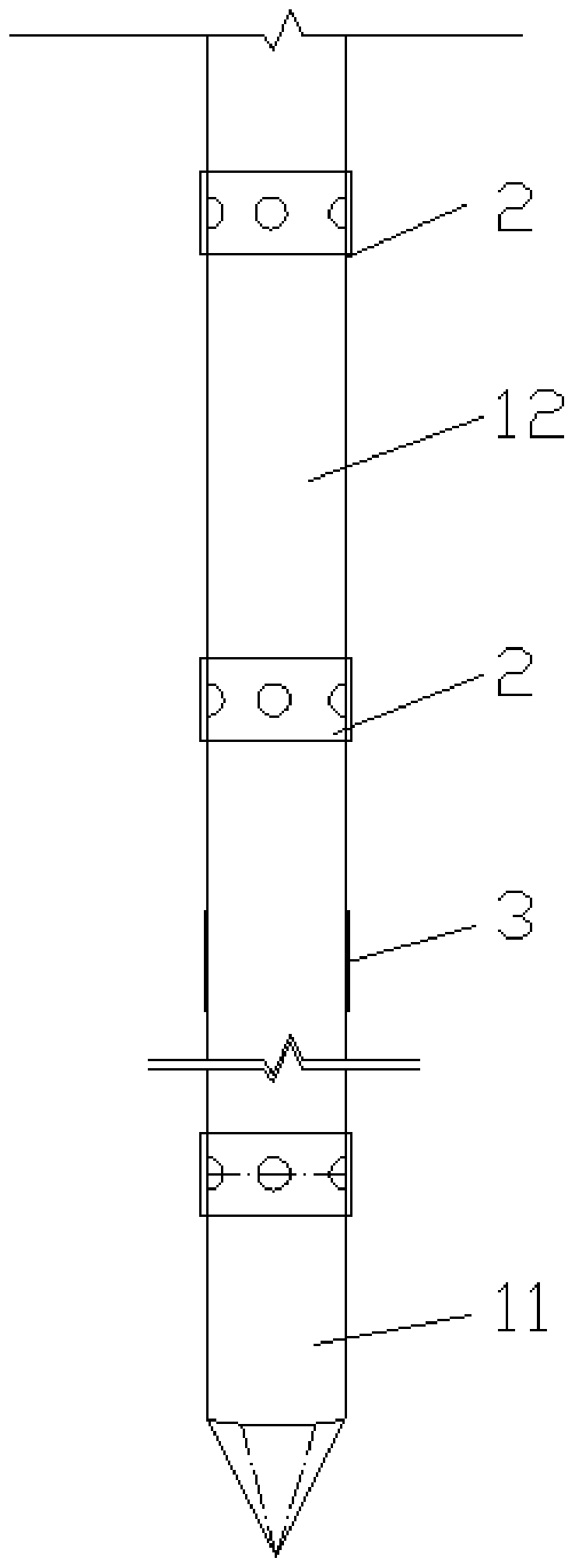

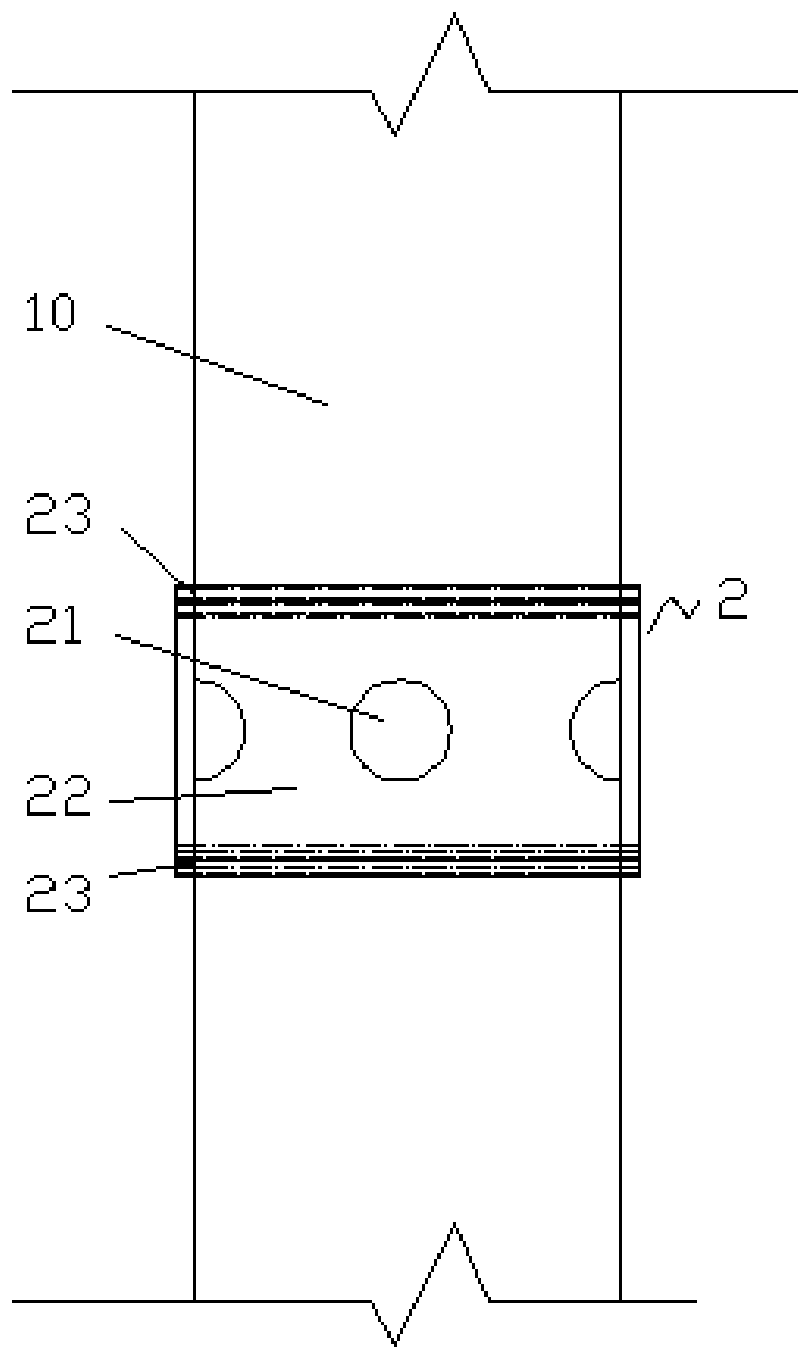

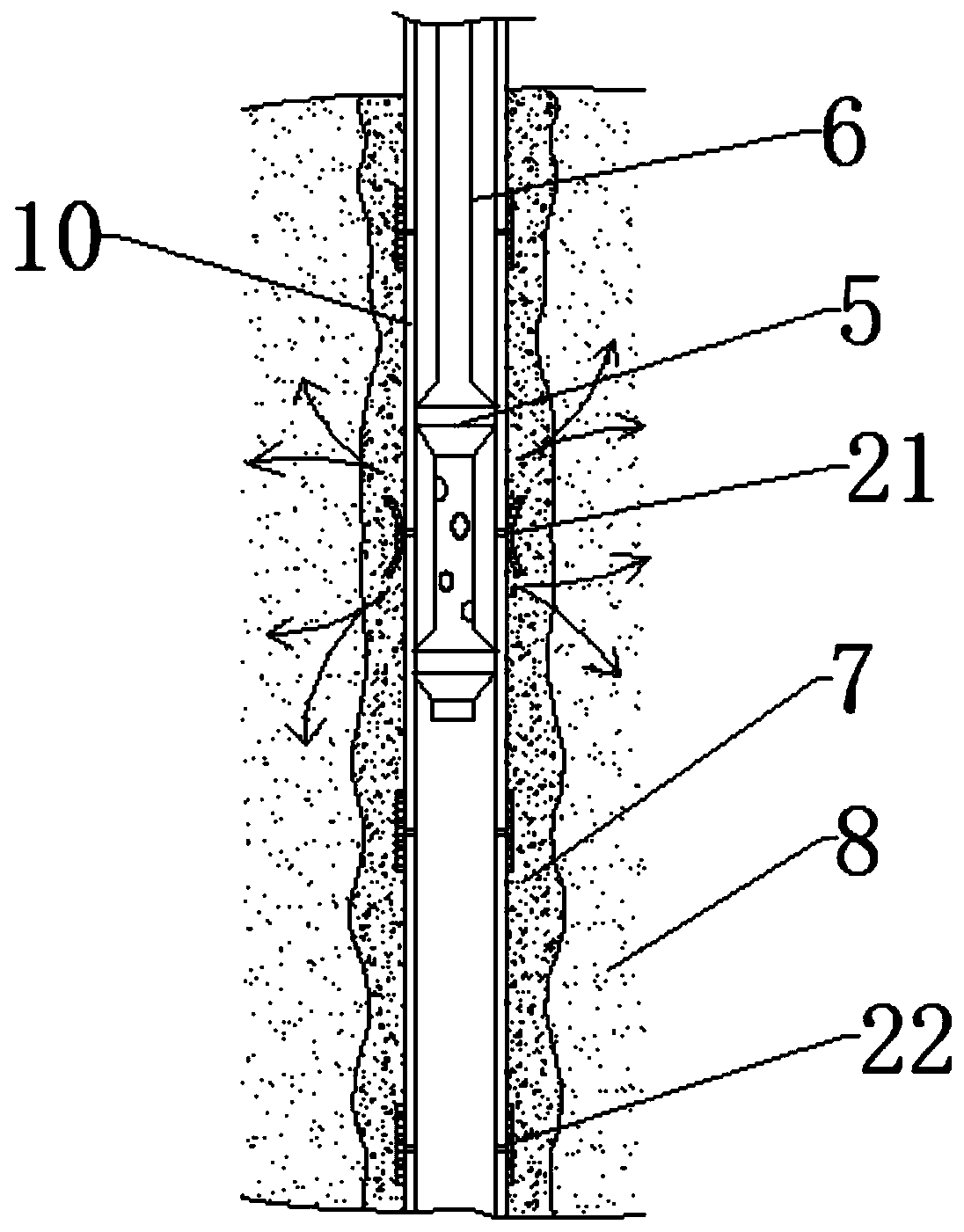

[0042] The application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain related inventions, rather than to limit the invention. It should also be noted that, for ease of description, only parts related to the invention are shown in the drawings.

[0043] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present application will be described in detail below with reference to the accompanying drawings and embodiments.

[0044] Below, this embodiment describes the detailed process of the application scheme with the following items:

[0045] A hydropower station has stored water, the dam crest elevation is 1385m, and the normal water storage elevation is about 1375m. There is water and sand gushing in the downstream,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com