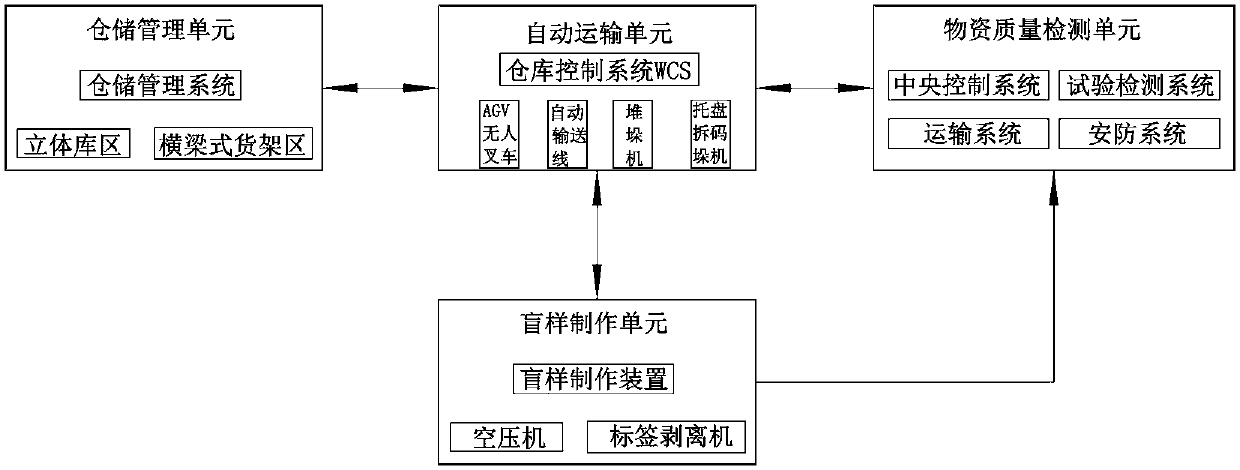

Electric power material storage and inspection integrated system and method

A technology of electric power materials and storage management system, applied in the field of integrated storage and inspection of electric power materials, can solve the undiscovered problems such as integration of storage and inspection of electric power materials, achieve the effect of improving material turnover rate, less impact, and improving support capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

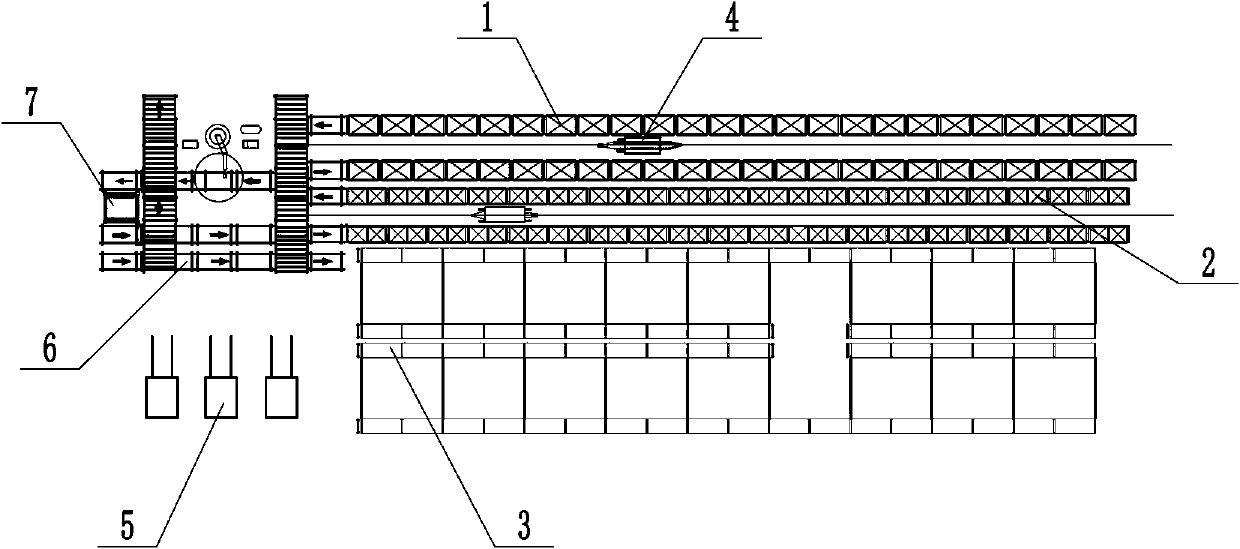

[0131] Example 1: Integration of storage and inspection of distribution transformers in the three-dimensional storage area

[0132] S01: The distribution transformer procurement contract is signed, and the material supply plan is generated. After the warehouse management system generates the material sampling inspection plan according to the material supply plan, it pushes the sampling inspection plan to the central control system of the material quality inspection unit, and the central control system generates a testing test plan, and Feedback the inspection test plan to the warehouse management system.

[0133] S02: The supplier completes the production preparation of distribution transformers according to the material supply plan. After the delivery conditions are met, the supplier fills in the material warehousing reservation application in the warehouse management system according to the material supply plan. After the reservation is approved, the warehouse management syst...

Embodiment example 2

[0139] Implementation case 2: Integration of storage and inspection of JP cabinets in the beam-type shelf area

[0140] S01: The procurement contract for JP cabinets is signed and a material supply plan is generated. After the warehouse management system generates a material sampling inspection plan according to the material supply plan, it pushes the sampling inspection plan to the central control system of the material quality inspection unit. The central control system generates a testing test plan and sends The inspection test plan is fed back to the warehouse management system.

[0141] S02: The supplier completes the production preparation of JP cabinets according to the material supply plan. After meeting the delivery conditions, the supplier fills in the material warehousing reservation application in the warehouse management system according to the material supply plan. Electric transformers are pre-allocated for storage space, and the specific arrival time of materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com