Method for Rapid Determination of Aluminum Content in Wheat Foods

A technology for rapid determination of aluminum content, applied in the measurement of color/spectral characteristics, etc., can solve the problems of low work efficiency, high detection cost, long sample processing time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

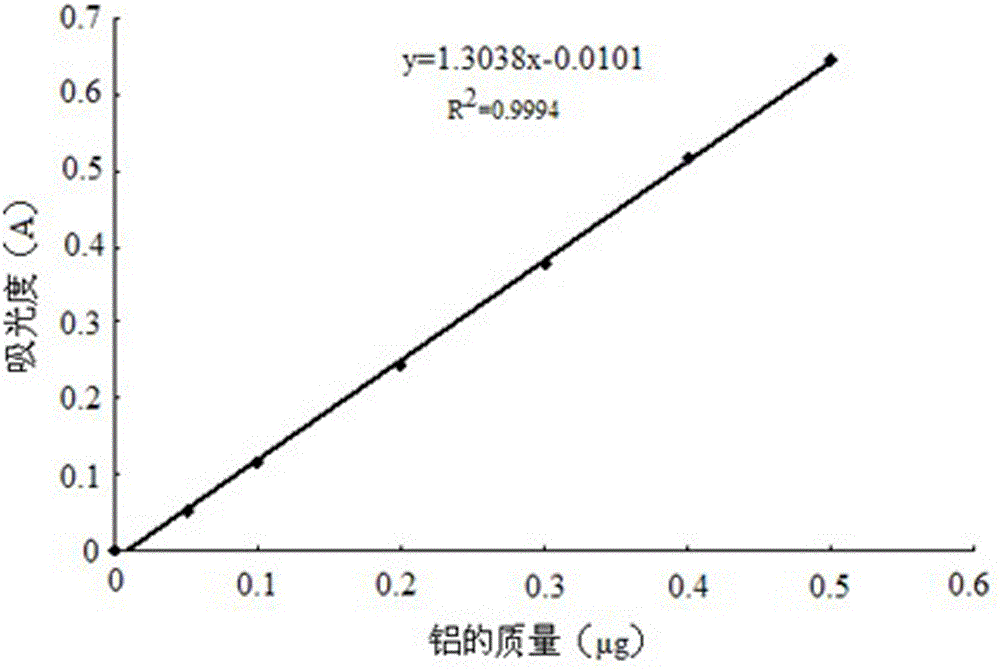

Embodiment 1

[0058] Weigh 0.1g of chromazurin S, dissolve in 100mL ethanol solution (1+1), mix well to obtain chromazurin S solution with a mass volume concentration of 1g / L; dissolve 3.0mL of emulsifier OP in 100mL of water, Make emulsifier OP solution; weigh 0.6g cetylpyridinium bromide, dissolve in 30mL ethanol (φ(C 2 h 5 OH)=95%), add water to dilute to 200mL to obtain cetylpyridine bromide solution; take 100mL of anhydrous ethylenediamine, add 200mL of pure water, and slowly add 190mL after cooling, the mass volume concentration is 1.19g / mL hydrochloric acid, stir well, and adjust the pH value to 6.7 to 7.0 to prepare ethylenediamine-hydrochloric acid buffer solution; use the aluminum standard stock solution with a mass volume concentration of 1.0 mg / mL to prepare a mass volume concentration of 0.5 μg / mL and 1.0 μg / mL, 2.0μg / mL, 3.0μg / mL, 4.0μg / mL and 5.0μg / mL six kinds of aluminum standard solutions; Each aluminum standard solution is processed as follows: draw 100μL aluminum stand...

Embodiment 2

[0062] Weigh 0.1g of chromazurin S, dissolve in 100mL ethanol solution (1+1), mix well to obtain chromazurin S solution with a mass volume concentration of 1g / L; dissolve 3.0mL of emulsifier OP in 100mL of water, Make emulsifier OP solution; weigh 0.6g cetylpyridinium bromide, dissolve in 30mL ethanol (φ(C 2 h 5 OH)=95%), add water to dilute to 200mL to obtain cetylpyridine bromide solution; take 100mL of anhydrous ethylenediamine, add 200mL of pure water, and slowly add 190mL after cooling, the mass volume concentration is 1.19g / mL hydrochloric acid, stir well, and use a pH meter to adjust the pH value to 6.7-7.0 to prepare ethylenediamine-hydrochloric acid buffer solution; prepare a mass volume concentration of 0.5 μg / mL with an aluminum standard stock solution with a mass volume concentration of 1.0 mg / mL , 1.0μg / mL, 2.0μg / mL, 3.0μg / mL, 4.0μg / mL and 5.0μg / mL six kinds of aluminum standard solutions; Each aluminum standard solution is processed as follows: draw 100μL alumin...

Embodiment 3

[0066] Weigh 0.1g of chromazurin S, dissolve in 100mL ethanol solution (1+1), mix well to obtain chromazurin S solution with a mass volume concentration of 1g / L; dissolve 3.0mL of emulsifier OP in 100mL of water, Make emulsifier OP solution; weigh 0.6g cetylpyridinium bromide (CPB), dissolve in 30mL ethanol (φ(C 2 h 5 OH)=95%), add water to dilute to 200mL to obtain cetylpyridine bromide solution; take 100mL of anhydrous ethylenediamine, add 200mL of pure water, and slowly add 190mL after cooling, the mass volume concentration is 1.19g / mL hydrochloric acid, stir well, and adjust the pH value to 6.7 to 7.0 to prepare ethylenediamine-hydrochloric acid buffer solution; use the aluminum standard stock solution with a mass volume concentration of 1.0 mg / mL to prepare a mass volume concentration of 0.5 μg / mL and 1.0 μg / mL, 2.0μg / mL, 3.0μg / mL, 4.0μg / mL and 5.0μg / mL six kinds of aluminum standard solutions; Each aluminum standard solution is processed as follows: draw 100μL aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com