A kind of LED full-color display panel and packaging method thereof

A technology of full-color display and packaging method, applied in the manufacturing of semiconductor devices, electrical components, semiconductor/solid-state devices, etc., can solve the problems of difficult calibration, low product yield, and high price, so as to reduce manufacturing difficulty and cost, and simplify inspection. Process, the effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

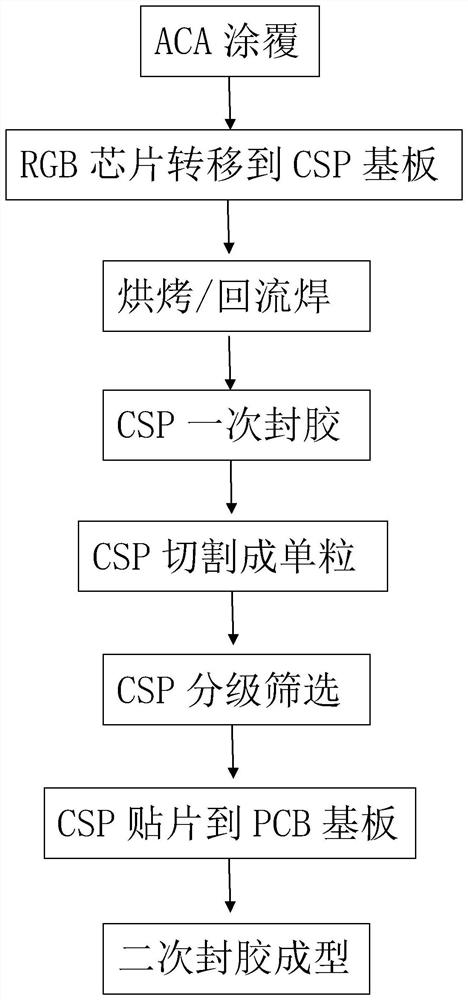

[0034] A kind of LED full-color display panel packaging method, such as figure 1 shown, including the following steps:

[0035] S1: Use ACA welding technology to seal the CSP device once, and cut the CSP device into single grains.

[0036] S11: Coating ACA on the CSP substrate.

[0037] ACA (Anisotropic Conductive Adhesive) is able to conduct electricity in the longitudinal direction, but not in the transverse direction. Therefore, the spacing between the light-emitting units can be greatly seen, and the use of ACA soldering technology instead of traditional solder paste printing can solve the problem that the yield rate of solder paste printed with small spacing is difficult to guarantee, and the cost is lower than that of using solder paste printing. During ACA coating, only one layer of ACA needs to be coated on the substrate, the coating process is convenient, the equipment used has no precision requirements, and the cost of the equipment is low.

[0038] Using ACA sold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com