A core-shell structure high-nickel ternary precursor and its preparation method, and a hollow-doped high-nickel ternary positive electrode material

A core-shell structure and precursor technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of poor conductivity, unstable cycle structure, and low initial capacity of high-nickel NCM, and achieve improved internal structure and easy design. Assembly and structural regulation, and the effect of improving cycling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

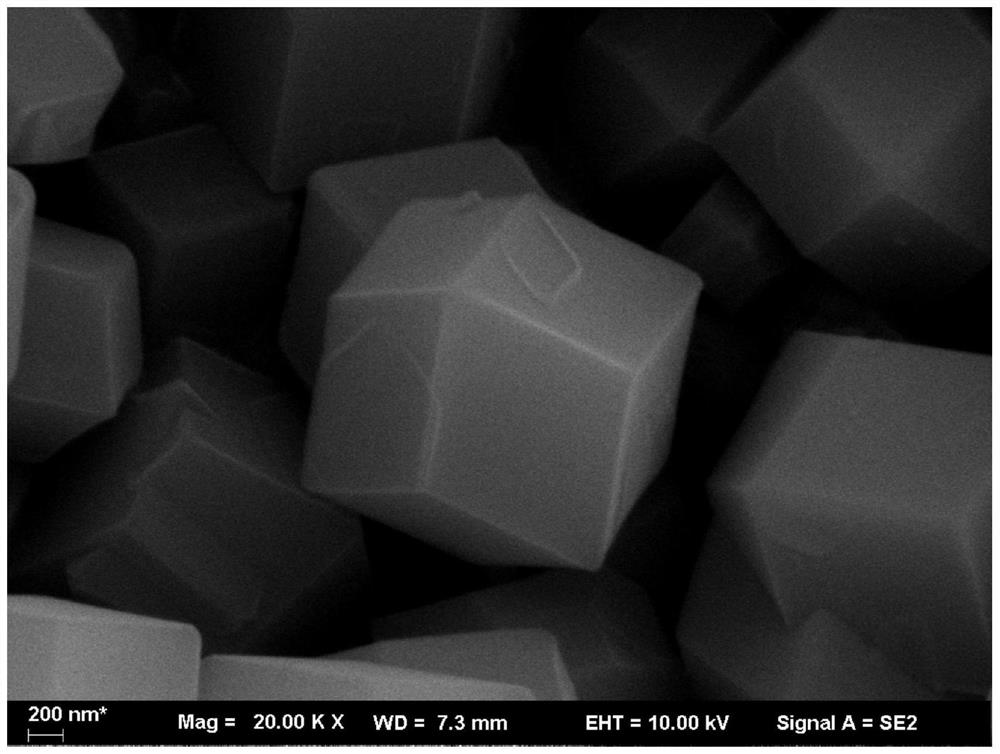

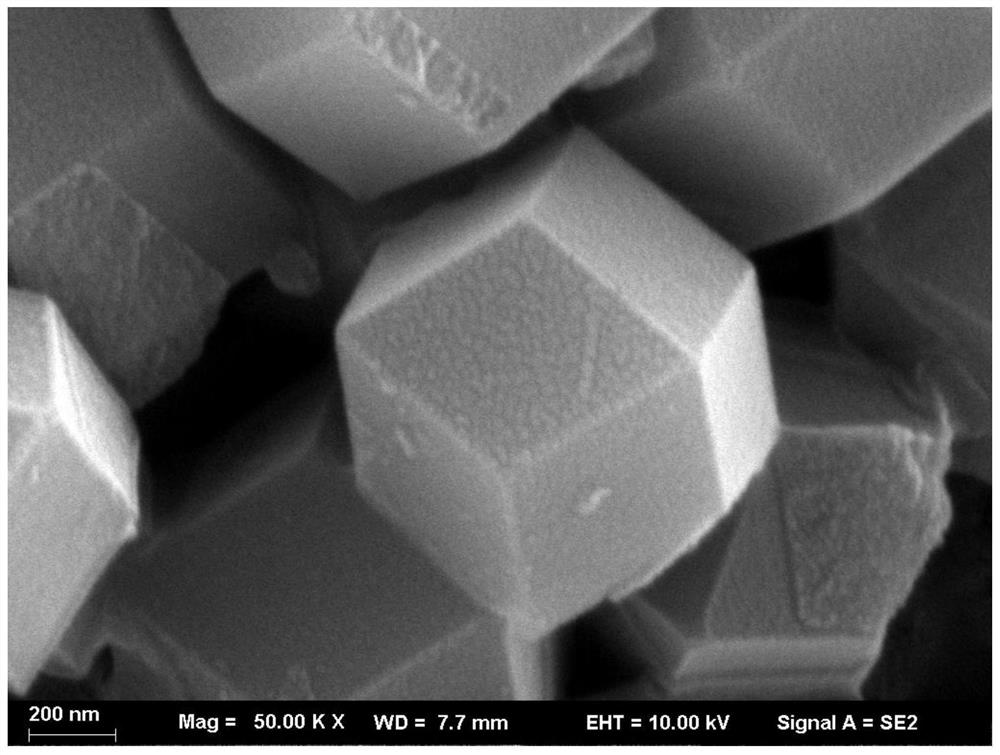

[0042] The preparation of a high-nickel ternary precursor with a core-shell structure includes the following steps:

[0043] (1) The concentration of zinc nitrate is adjusted and controlled at 2mol / L; the concentration of 2-methylimidazole is adjusted and controlled at 4mol / L;

[0044] (2) Slowly add the uniformly stirred metal salt solution into the 2-methylimidazole solution, stir for 30min, and let stand for 24h;

[0045] (3) The Zn-MOF was washed by centrifugation, dried at 80°C for 8 hours, and then soaked in 0.1mol / L boric acid solution for 6 hours;

[0046] (4) Industrial 28% ammonia water is mixed with deionized water and the concentration is adjusted to be 10mol / L; NaOH is mixed with deionized water to adjust the concentration to be 4mol / L;

[0047] (5) dissolving soluble nickel nitrate, cobalt nitrate, and manganese nitrate with a molar ratio of Ni:Co:Mn=7:2:1 and a total concentration of 2mol / L in hot water at 70°C, and stirring until completely dissolved;

[0048...

Embodiment 2

[0058] The preparation of a high-nickel ternary precursor with a core-shell structure includes the following steps:

[0059] (1) The concentration of zinc nitrate is adjusted and controlled at 2mol / L; the concentration of 2-methylimidazole is adjusted and controlled at 4mol / L;

[0060] (2) Slowly add the uniformly stirred metal salt solution into the 2-methylimidazole solution, stir for 30min, and let stand for 24h;

[0061] (3) The Zn-MOF was washed by centrifugation, dried at 80°C for 12h, and then soaked in 0.05mol / L boric acid solution for 10h;

[0062] (4) Industrial 28% ammonia water is mixed with deionized water and the concentration is adjusted to be 10mol / L; NaOH is mixed with deionized water to adjust the concentration to be 4mol / L;

[0063] (5) dissolving soluble nickel nitrate, cobalt nitrate, and manganese nitrate with a molar ratio of Ni:Co:Mn=6:2:2 and a total concentration of 2mol / L in hot water at 70°C, and stirring until completely dissolved;

[0064] (6) P...

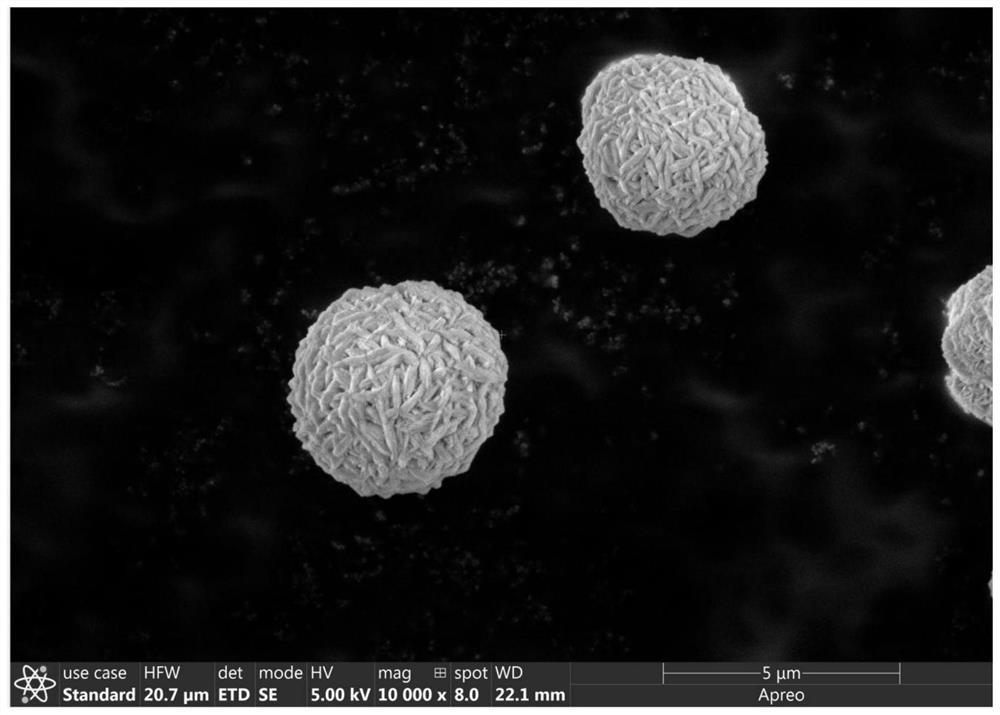

Embodiment 3

[0069] The preparation of a high-nickel ternary precursor with a core-shell structure includes the following steps:

[0070] (1) The concentration of zinc nitrate is adjusted and controlled at 1.5mol / L; the concentration of 2-methylimidazole is adjusted and controlled at 3mol / L;

[0071] (2) Slowly add the uniformly stirred metal salt solution into the 2-methylimidazole solution, stir for 15 minutes, and let stand for 20 hours;

[0072] (3) The Zn-MOF was washed by centrifugation, dried at 100°C for 6h, and then soaked in 0.02mol / L boric acid solution for 24h

[0073] (4) Industrial 28% ammonia water is mixed with deionized water and the concentration is adjusted to be 10mol / L; NaOH is mixed with deionized water to adjust the concentration to be 4mol / L;

[0074] (5) dissolving soluble nickel sulfate, cobalt sulfate, and manganese sulfate with a molar ratio of Ni:Co:Mn=8:1:1 and a total concentration of 2mol / L in hot water at 70°C, and stirring until completely dissolved;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com