Cashew nut shell opening machine with shell separation function

A functional, cashew nut technology, applied in the field of shell openers, can solve problems such as hand scratches and hand injuries, and achieve the effect of preventing hands from being scratched

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

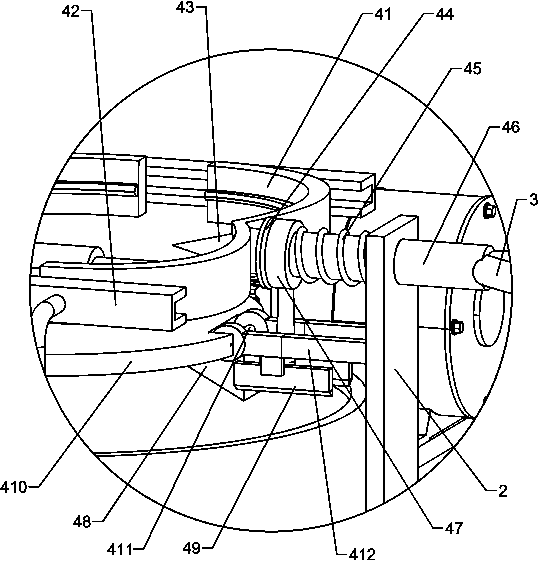

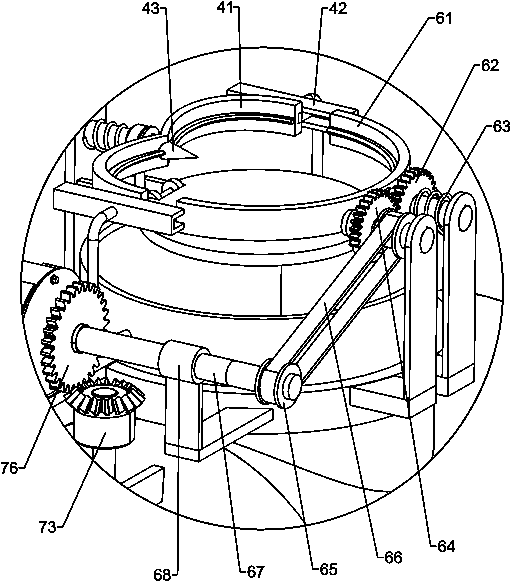

[0023] A cashew nut sheller with shell separation function, such as Figure 1-5 As shown, it includes a mounting frame 2, a pull ring 3, a clamping mechanism 4, a geared motor 5, and an opening mechanism 6. The geared motor 5 is installed on the rear side of the mounting frame 2, and the clamping mechanism is installed on the right side of the mounting frame 2. 4. A pull ring 3 is connected to the clamping mechanism 4, and a shell opening mechanism 6 is installed on the left side of the installation frame 2, and the shell opening mechanism 6 is connected to the reduction motor 5 through transmission.

[0024] The clamping mechanism 4 includes a W-shaped clamping tool rest 41, a tool rest guide rail 42, a cone head 43, a guide ring 44, a return spring 45, a connecting rod 46, a sliding connection frame 47, a wedge-shaped top block 48, a guide plate 49, and a bottom plate 410, connecting shaft 411 and fixed rod 412, two tool rest guide rails 42 are connected to the upper right s...

Embodiment 2

[0028] On the basis of Example 1, such as Figure 1-3 Shown, also include separation mechanism 7, separation mechanism 7 includes separation bucket 71, mounting rod 72, double-headed bevel gear rod 73, driven gear 74, separation rod 75 and transmission gear 76, the bottom of installation frame 2 is connected with Separation bucket 71, separation bucket 71 is connected with mounting frame 2, and the rear side upper part of separation bucket 71 is connected with installation rod 72, and the inner rotation type of installation rod 72 is connected with double-ended bevel gear rod 73, double-ended bevel gear rod 73 lower side The separating barrel 71 of the rotating type is connected with a separating rod 75, and the rear end of the separating rod 75 is connected with a driven gear 74, and the driven gear 74 meshes with the double-headed bevel gear rod 73, and the right side outer wall of the power shaft 67 is connected with a transmission gear. 76, transmission gear 76 is meshed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com