Alkali aluminosilicate flexible glass suitable for ultraviolet laser processing

A technology of silicate glass and flexible glass, applied in the field of flexible glass, to avoid the reduction of average transmittance, reduce glass coloration, and solve the problem of ultraviolet picosecond laser processing

Active Publication Date: 2020-08-14

山东柔光新材料有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0014] In order to overcome the defects of the prior art, the present invention designs an alkali-aluminosilicate flexible glass suitable for ultraviolet laser processing, realizes high ultraviolet absorption and high visible light transmission of the alkali-aluminosilicate flexible glass, and effectively solves the problem of such problems. The problem of ultraviolet picosecond laser processing of flexible glass lays the foundation for the application of flexible glass in folding mobile phones and flexible photovoltaic products

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0037] Example 1. Flexible glass includes 3.0% of UV absorber composition and 97.0% of oxide of alkali aluminosilicate glass batch.

Embodiment 2

[0038] Example 2, flexible glass comprising 5.0% of UV absorber composition and 95.0% of oxide of alkali aluminosilicate glass batch.

Embodiment 3

[0039] Example 3, the flexible glass comprises 4.0% of the ultraviolet absorber composition and 96.0% of the oxide of the alkali-aluminosilicate glass batch.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

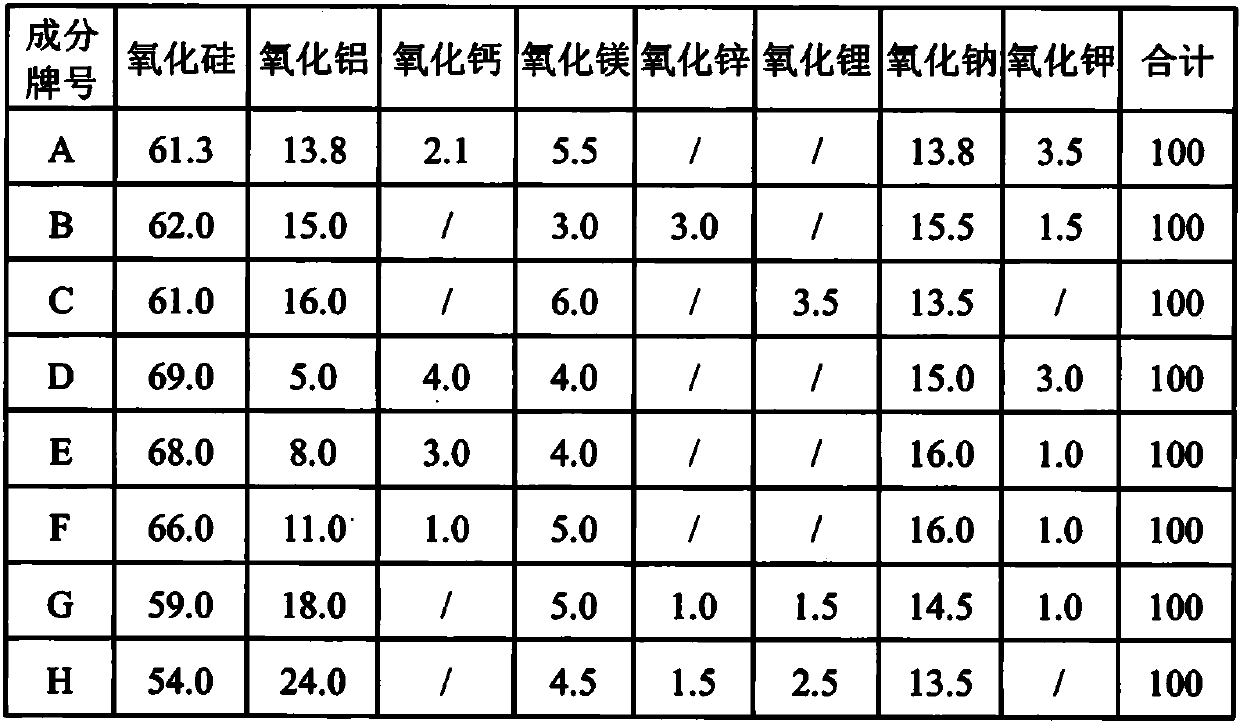

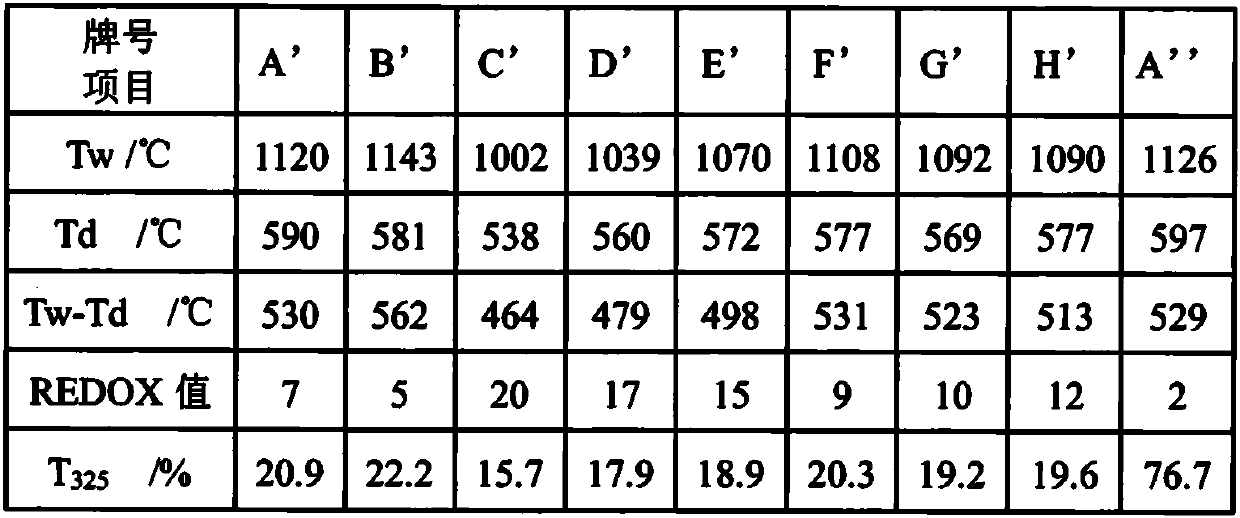

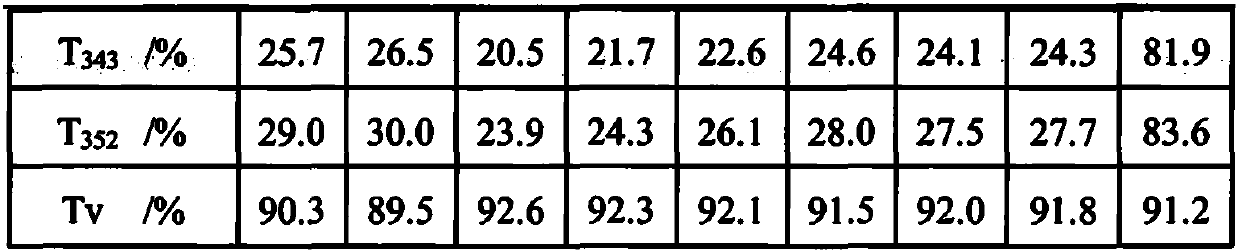

The invention discloses alkali aluminosilicate flexible glass suitable for ultraviolet laser processing and belongs to the technical field of flexible glass. The alkali aluminosilicate flexible glassis prepared from 3.0 to 5.0 percent of an ultraviolet ultraviolet absorbent composition and 95.0 to 97.0 percent of oxide of an alkali aluminosilicate glass batch, wherein the ultraviolet absorbent composition comprises ferric oxide, molybdenum oxide, erbium oxide and potassium nitrate, and the ratio of ferric oxide to molybdenum oxide to erbium oxide to potassium nitrate in parts by weight is (1-3): (10-20): (4-8): (70-80); the oxide of the alkali aluminosilicate glass batch comprises the following, by weight, 54.0%-69.0% of silicon oxide, 5.0%-24.0% of aluminum oxide, 13.5%-18.0% of monovalent oxide and 4%-6% of divalent oxide, wherein the monovalent oxide is prepared from 0 to 3.5 percent of lithium oxide, 13.5 to 16.0 percent of sodium oxide and 0 to 3.5 percent of potassium oxide; andthe divalent oxide comprises 0-4.0% of calcium oxide, 3.0-6.0% of magnesium oxide and 0-3.0% of zinc oxide. According to the invention, high ultraviolet absorption and high visible light transmissionare realized, and a foundation is laid for application of the flexible glass in folding mobile phones and flexible photovoltaic products.

Description

technical field [0001] The invention belongs to the technical field of flexible glass, and relates to alkali aluminosilicate flexible glass, in particular to alkali aluminosilicate flexible glass suitable for ultraviolet laser processing. Background technique [0002] With the development of electronic information display products in the direction of thinner, larger, flexible, high-resolution, and high-contrast, under the traction of demand, electronic glass also develops in the direction of thinner, larger, and flexible. When the glass thickness reaches 0.1 When it is below mm (100μm), the glass will show excellent flexibility, so flexible glass was born. [0003] Flexible glass will change the way of flat glass storage and storage, which can meet the bending and winding method, and will realize roll-to-roll process technology in terms of processing and use. Technological workers have proposed many application scenarios for flexible glass, including flexible displays, flex...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C03C4/08C03C1/00C03C3/095C03C3/087

CPCC03C4/085C03C1/00C03C3/095C03C3/087

Inventor 田英良侯延升徐正本徐强

Owner 山东柔光新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com