Alkali aluminosilicate flexible glass with ultraviolet absorption and low surface tension

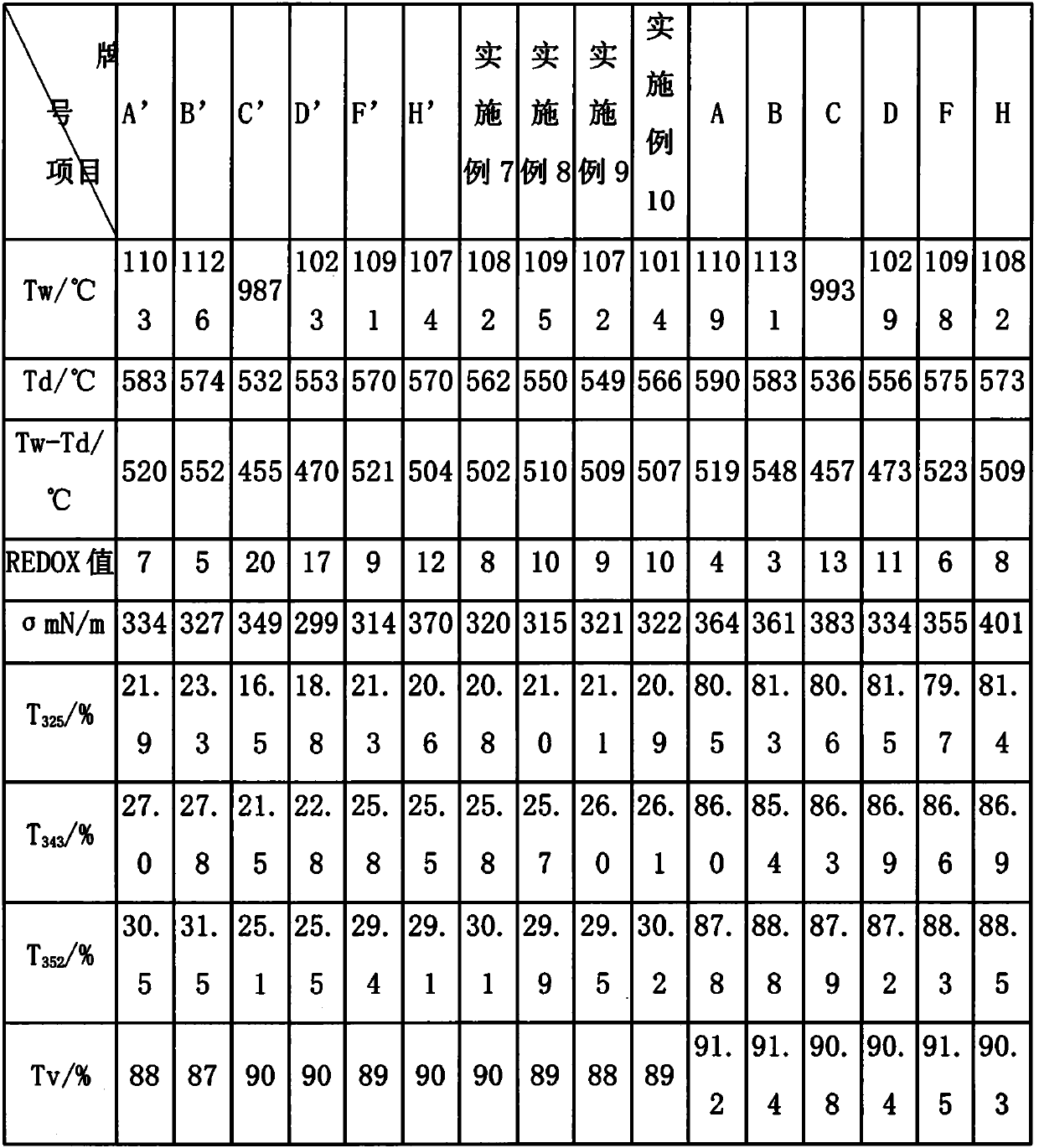

A low surface tension, silicate glass technology, applied in the field of flexible glass, can solve the problems of high surface tension of glass melt, unfavorable flexible glass forming, low quality of picosecond UV laser processing, etc. The information shows the effect of product application and solving the problem of picosecond UV laser processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] An alkali aluminosilicate flexible glass with both ultraviolet absorption and low surface tension, comprising 4% of glass melt active material composition, 4% of ultraviolet absorber composition and alkali aluminosilicate glass by mass percentage Material 92%, wherein the glass melt active material composition includes 1.5g of niobium pentoxide, 25g of antimony trioxide, 37.5g of potassium nitrate, and the ultraviolet absorber composition includes: 2g of ferric oxide, 15g of molybdenum oxide, erbium oxide 6g and potassium nitrate 37.5g, the alkali aluminosilicate glass batch material comprises: silicon oxide 61.3g, aluminum oxide 13.8g, sodium oxide 12.8g, potassium oxide 3.5g, calcium oxide 2.1g, magnesium oxide 5.5g, Zirconium dioxide 1g.

Embodiment 2

[0031] An alkali-aluminosilicate flexible glass with both ultraviolet absorption and low surface tension, comprising 3% of glass melt active material composition, 5% of ultraviolet absorber composition, and alkali-aluminosilicate glass compound Material 92%, wherein the glass melt active material composition includes niobium pentoxide 1g, antimony trioxide 20g, potassium nitrate 35g, and the ultraviolet absorber composition includes: ferric oxide 1g, molybdenum oxide 10g, erbium oxide 4g and Potassium nitrate 35g, the alkali aluminosilicate glass batch material comprises: silicon oxide 62g, aluminum oxide 15g, sodium oxide 15.5g, potassium oxide 1.5g, magnesium oxide 3g, zinc oxide 3g.

Embodiment 3

[0033] An alkali aluminosilicate flexible glass with both ultraviolet absorption and low surface tension, comprising 5% of glass melt active material composition, 3% of ultraviolet absorber composition, alkali aluminosilicate glass compound Material 92%, wherein glass melt active material composition comprises niobium pentoxide 2g, antimony trioxide 30g, potassium nitrate 40g, and ultraviolet absorber composition comprises: ferric oxide 3g, molybdenum oxide 20g, erbium oxide 8g and Potassium nitrate 40g, the alkali aluminosilicate glass batch material includes: silicon oxide 61g, aluminum oxide 16g, lithium oxide 3.5g, sodium oxide 13.5g, magnesium oxide 6g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com