A process equipment for producing oleic acid from plant waste oil

A technology for the production of oleic acid and plant waste, which is applied to the recovery of fat oil/fatty acid from waste materials, fatty acid production, and recycling technology. The effect of increasing reaction time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

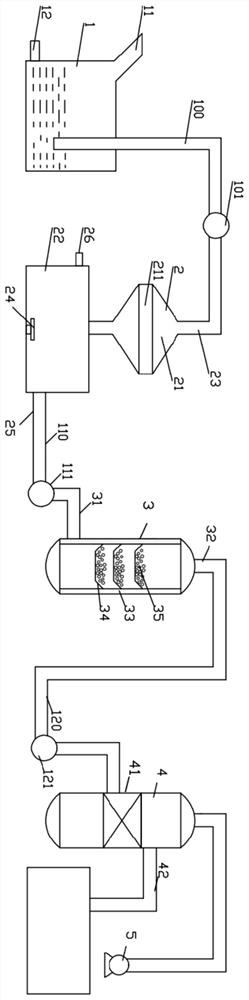

[0037] A device for producing oleic acid from plant waste oil, including a pretreatment device, a cracking device and a purification device; the pretreatment device includes a pickling tank 1 and a settling reactor 2, and the top of the pickling tank 1 is provided with a first feed port 11. A waste material outlet 12 is provided below the side; the sedimentation reactor 2 includes a reactor body 21 and a liquid storage tank 22, and the upper end of the reactor body 21 is provided with a second feed port 23; the sedimentation reactor 2 and the pickling tank 1 pass through The first feed pipe 100 is connected, one end of the first feed pipe 100 is immersed in the liquid of the pickling tank 1, and the other end is connected to the second feed port 23; the liquid storage tank 22 is arranged under the reaction kettle body 21 , connected to the reactor body 21 through the second feed pipe 110; a stirring device 24 is also provided inside the liquid storage tank 22, a first discharge...

Embodiment 2

[0060] A device for producing oleic acid from plant waste oil, including a pretreatment device, a cracking device and a purification device; the pretreatment device includes a pickling tank 1 and a settling reactor 2, and the top of the pickling tank 1 is provided with a first feed port 11. A waste material outlet 12 is provided below the side; the sedimentation reactor 2 includes a reactor body 21 and a liquid storage tank 22, and the upper end of the reactor body 21 is provided with a second feed port 23; the sedimentation reactor 2 and the pickling tank 1 pass through The first feed pipe 100 is connected, one end of the first feed pipe 100 is immersed in the liquid of the pickling tank 1, and the other end is connected to the second feed port 23; the liquid storage tank 22 is arranged under the reaction kettle body 21 , connected to the reactor body 21 through the second feed pipe 110; a stirring device 24 is also provided inside the liquid storage tank 22, a first discharge...

Embodiment 3

[0083] A device for producing oleic acid from plant waste oil, including a pretreatment device, a cracking device and a purification device; the pretreatment device includes a pickling tank 1 and a settling reactor 2, and the top of the pickling tank 1 is provided with a first feed port 11. A waste material outlet 12 is provided below the side; the sedimentation reactor 2 includes a reactor body 21 and a liquid storage tank 22, and the upper end of the reactor body 21 is provided with a second feed port 23; the sedimentation reactor 2 and the pickling tank 1 pass through The first feed pipe 100 is connected, one end of the first feed pipe 100 is immersed in the liquid of the pickling tank 1, and the other end is connected to the second feed port 23; the liquid storage tank 22 is arranged under the reaction kettle body 21 , connected to the reactor body 21 through the second feed pipe 110; a stirring device 24 is also provided inside the liquid storage tank 22, a first discharge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com