Stable adjusting device for automobile part electrophoresis buffer solution

A technology for electrophoresis buffer and auto parts, applied in the direction of electrophoresis plating, electrolytic coating, electrolysis process, etc., can solve problems such as suspension, and achieve the effect of easy dressing change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

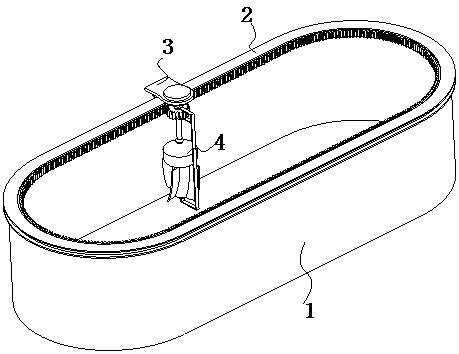

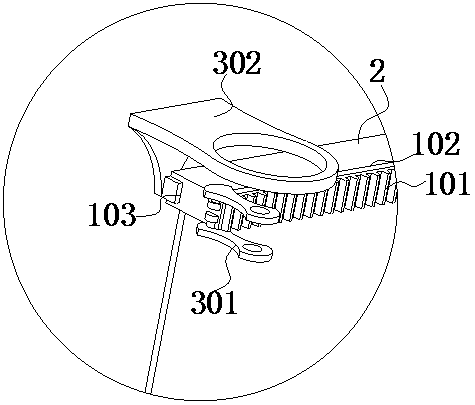

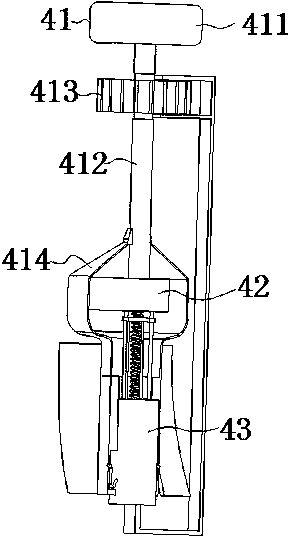

[0024] Embodiment one, such as Figure 1-7As shown, a device for stabilizing the electrophoresis buffer of auto parts includes an electrophoresis tank 1, a guide rail 2 is fixedly installed on the top of the electrophoresis tank 1, and a bracket 3 is slidably connected to the upper surface of the guide rail 2, and a mixing bracket 3 is fixedly installed inside the bracket 3. Material mechanism 4, the material mixing mechanism 4 is located inside the electrophoresis tank 1, the material mixing mechanism 4 meshes with the guide rail 2, the inner side of the guide rail 2 is provided with tooth grooves 101, the upper and lower sides of the guide rail 2 are provided with limiting grooves 102, the guide rail 2 The outer side is provided with a sliding groove 103, the mixing mechanism 4 includes a power mechanism 41, the power mechanism 41 is rotatably connected to the inside of the bracket 2, the bottom end of the power mechanism 41 is sleeved with a differential mechanism 42, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com