Low-water-level precipitation vacuum and surcharge united preloading reinforcement deep soft foundation method and system

A combined stacking and vacuum technology, applied in basic structure engineering, soil protection, construction, etc., can solve the problems of poor reinforcement effect of deep soft soil, insufficient reinforcement depth, and high stacking cost, so as to shorten the consolidation time and speed up the process. Pumping speed, the effect of reducing the vacuum preloading cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

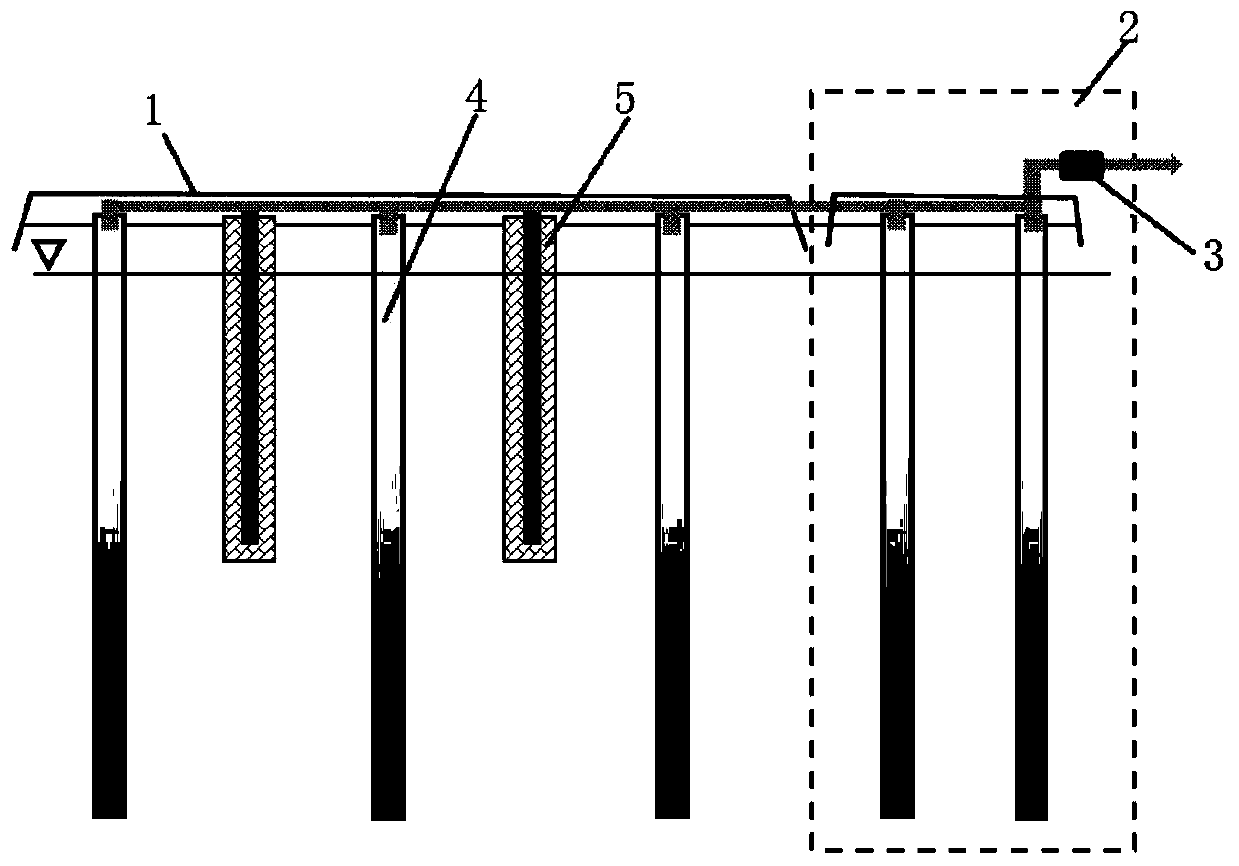

[0039] 1. The plastic drainage board is of SPB-B type, with a thickness of 4mm, a width of 100mm, and a permeability coefficient of 5*10-3cm3 / s. It is laid on a soft soil foundation for 25m; Wrapped with filter cloth, the lower end of the tube is equipped with a filter screen with a hole diameter of 300mm and a depth of 15m. Arrange the plastic drainage boards in a square with an interval of 1m, and arrange a dewatering well in the center of the square. Arranged as Figure 4 ;

[0040] 2. Leave an area of 8*8m on the soft soil foundation 2 In the water drawing area, sand cushions are laid out on the soft ground and technical areas respectively, and drainage pipes are laid out in the sealing membrane. Connect the drain hose to the vacuum pump.

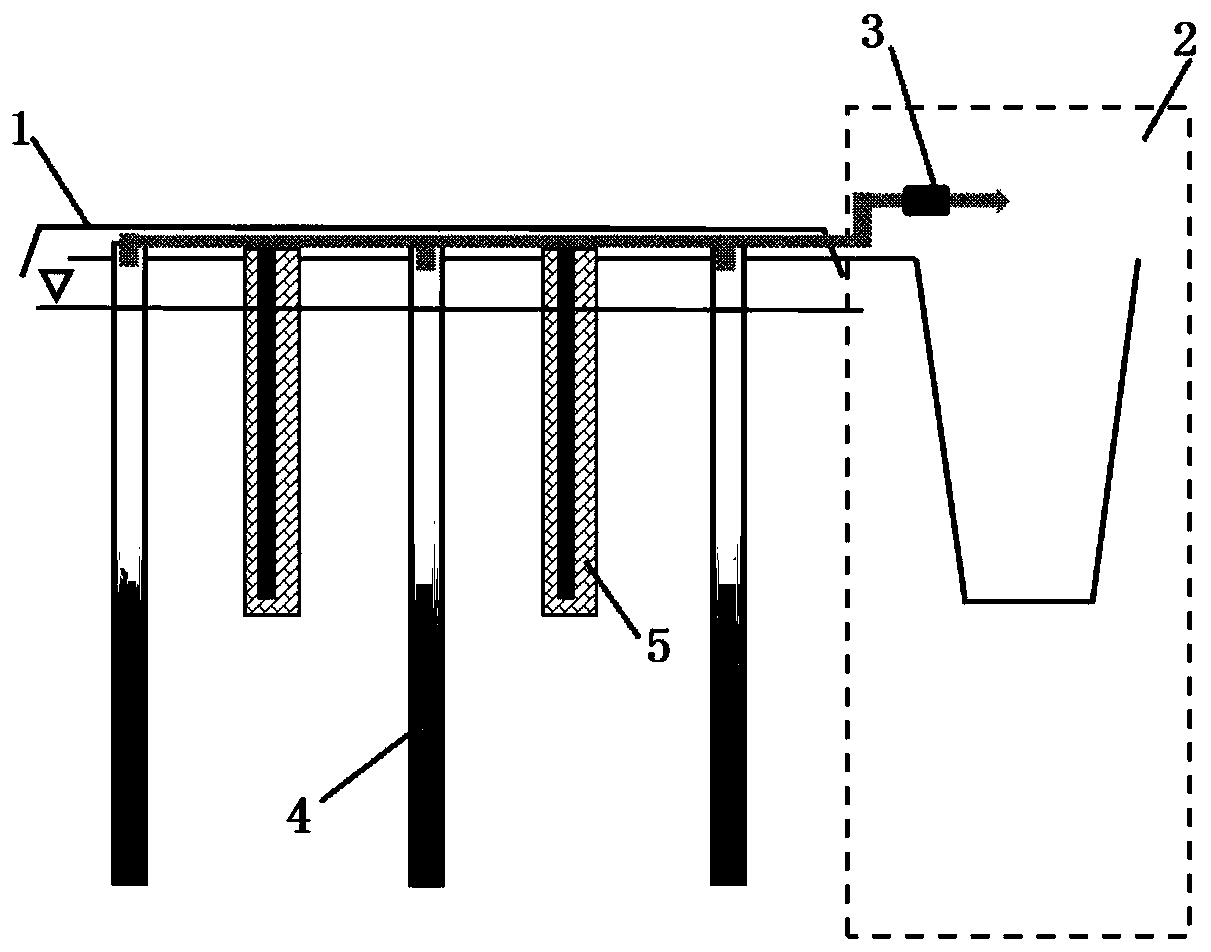

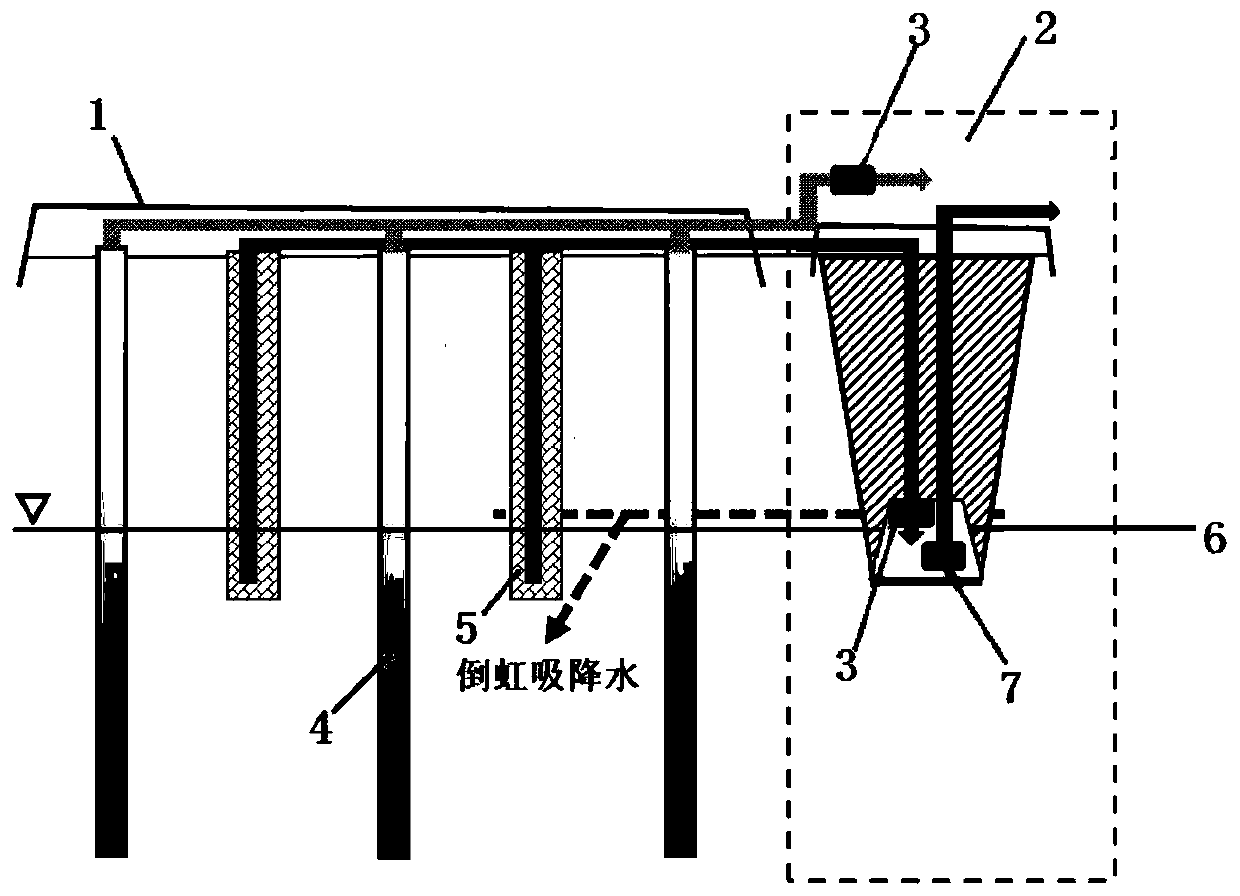

[0041] 3. Through the vacuum preloading method, the deep soft soil foundation will be constructed for one month, and part of the water in the soft soil foundation will be drained. At this time, the vacuum preloading drainage effec...

Embodiment 2

[0048] 1. The plastic drainage board is of SPB-B type, with a thickness of 4mm, a width of 100mm, and a permeability coefficient of 5*10 -3 cm 3 / s, 20m laid on the soft soil foundation; the dewatering well is made of steel pipe, the pipe wall is covered with leak holes, the surface is wrapped with filter cloth, and the lower end of the pipe is equipped with a filter screen with a hole diameter of 300mm and a depth of 10m. Arrange plastic drainage boards in a square with a spacing of 0.8m, and arrange a dewatering well in the center of the square;

[0049] 2. Leave an area of 6*6m on the soft soil foundation 2 In the water drawing area, sand cushions are laid out on the soft ground and technical areas respectively, and drainage pipes are laid out in the sealing membrane. Connect the drain hose to the vacuum pump. Lay a sealing film on the sand cushion;

[0050] 3. Through the vacuum preloading method, the deep soft soil foundation will be constructed for two months to dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com