Energy-saving underground pollution discharge pipeline

A technology for sewage pipes and pipes, which is applied in sewer pipe systems, roads, roads, etc., and can solve the problems of multiple resources, increased cost of sewage degreasing, and excessive oil pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

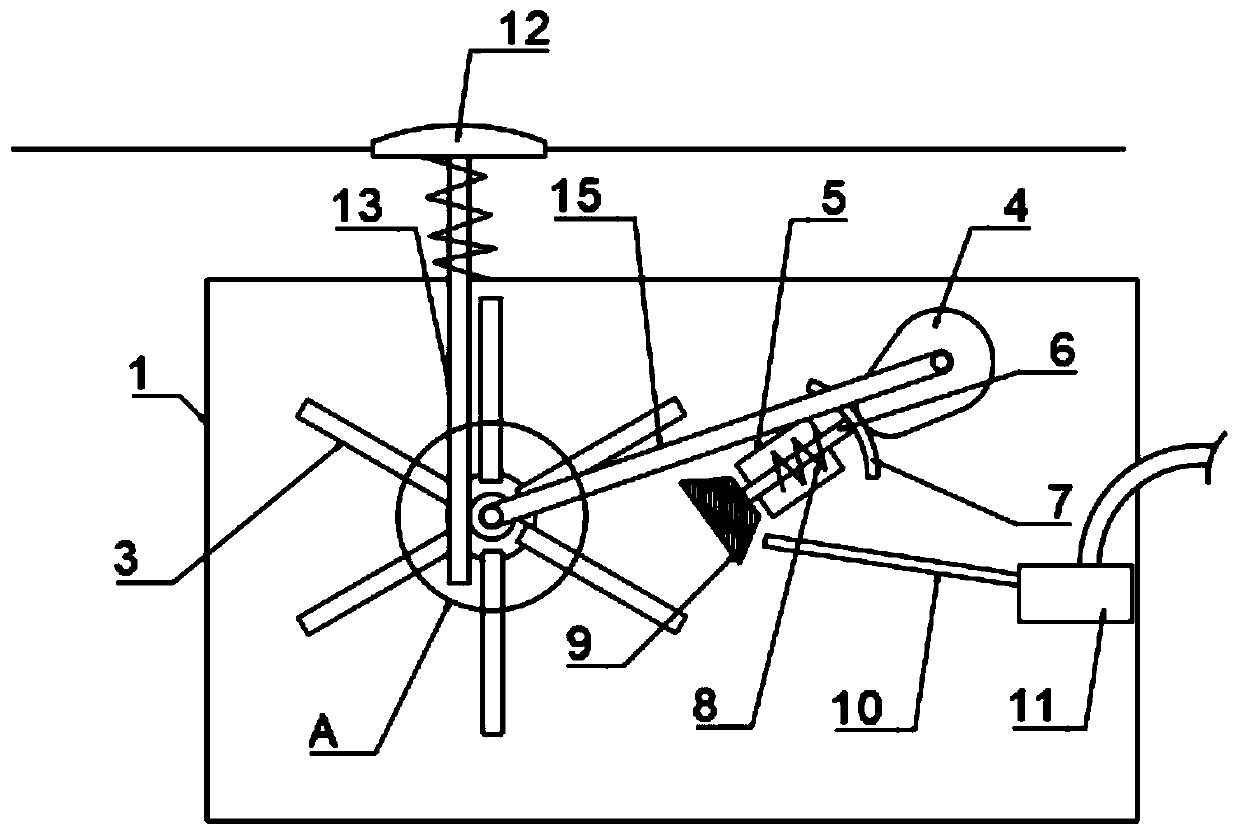

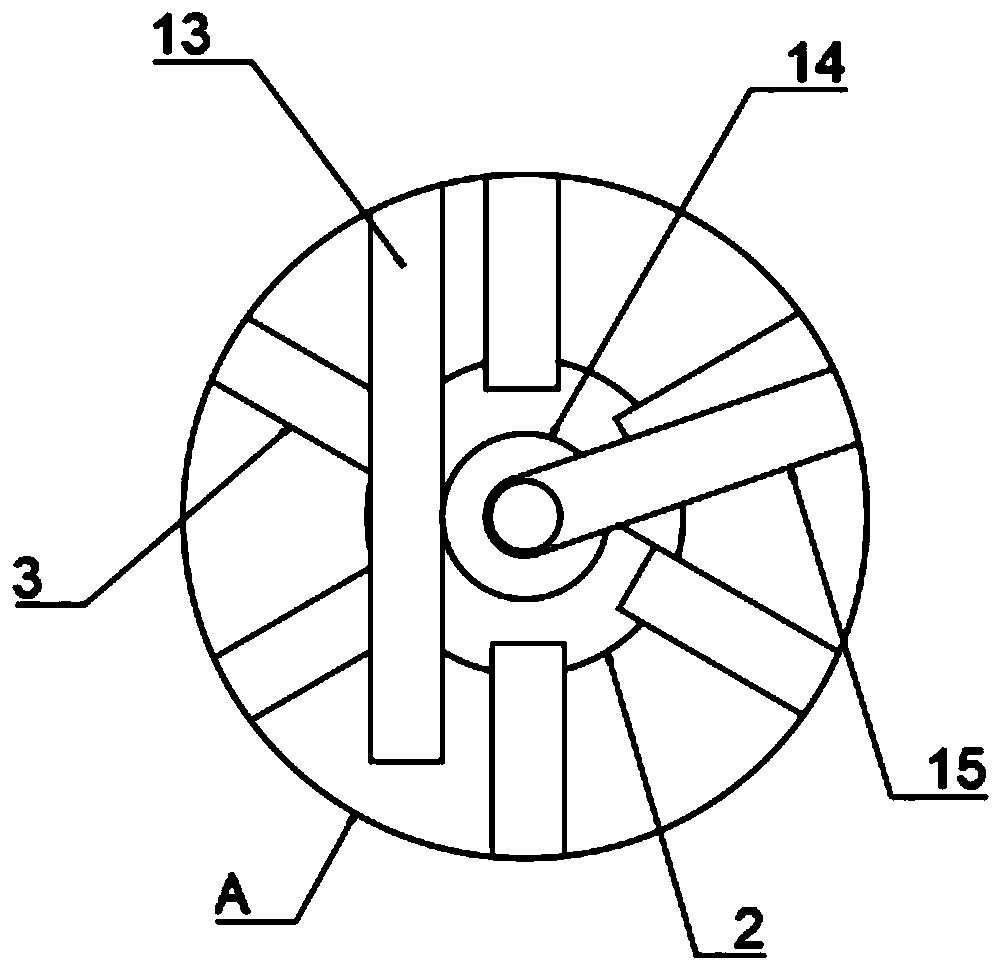

[0020] refer to Figure 1-2 , an energy-saving underground sewage pipeline, including a pipeline body 1 located under the ground, a rotating shaft 2 is installed on the inner wall of the pipeline body 1, and a plurality of fan blades 3 are evenly distributed on the outer wall of the rotating shaft 2, and when sewage is discharged in the pipeline , under the contact between the water flow and the fan blades 3 and the impact of the water flow, a plurality of fan blades 3 are driven to rotate, and a cam 4 is installed in the pipe body 1 through a rotating rod, and a bearing is fixedly embedded on the inner wall of the pipe body 1, and the rotating shaft 2 and the end of the rotating rod are inserted in the bearing and fixedly connected with the inner ring of the bearing, a belt 15 is set between the rotating shaft 2 and the rotating rod, a pulley is fixed on the outer wall of the end of the rotating shaft 2 and the rotating rod, and there are 15 sets of belts On the outer walls o...

Embodiment 2

[0025] The difference from Embodiment 1 is that there is a deceleration belt 12 moving on the ground, the lower side wall of the deceleration belt 12 is fixed with a tooth plate 13, and the outer wall of the tooth plate 13 is provided with a deceleration belt 12 and the upper side wall of the pipeline 1. Between the return spring, the end of the rotating shaft is also fixed with the gear 14 meshed with the tooth plate 13. When the vehicle passes the deceleration belt 12, the deceleration belt 12 and the tooth plate 13 are squeezed to move down, and the tooth plate 13 drives the gear. 14 rotates, and then drives the rotating shaft 2 to rotate, can drive the rotating shaft to rotate through the combination of water flow impact and vehicle extrusion deceleration belt 12 moving down, or adopt the single mode of water flow impact and vehicle extrusion deceleration belt 12 moving down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com