Integral sprayed wall body structure with internal and external molds

An internal and external mold, integral technology, applied in the direction of building structure, building components, walls, etc., can solve the problems of weak reinforcement of the wall layer, rebound of pulp particles, wall cracking, etc., to achieve good integrity, not easy to crack, Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

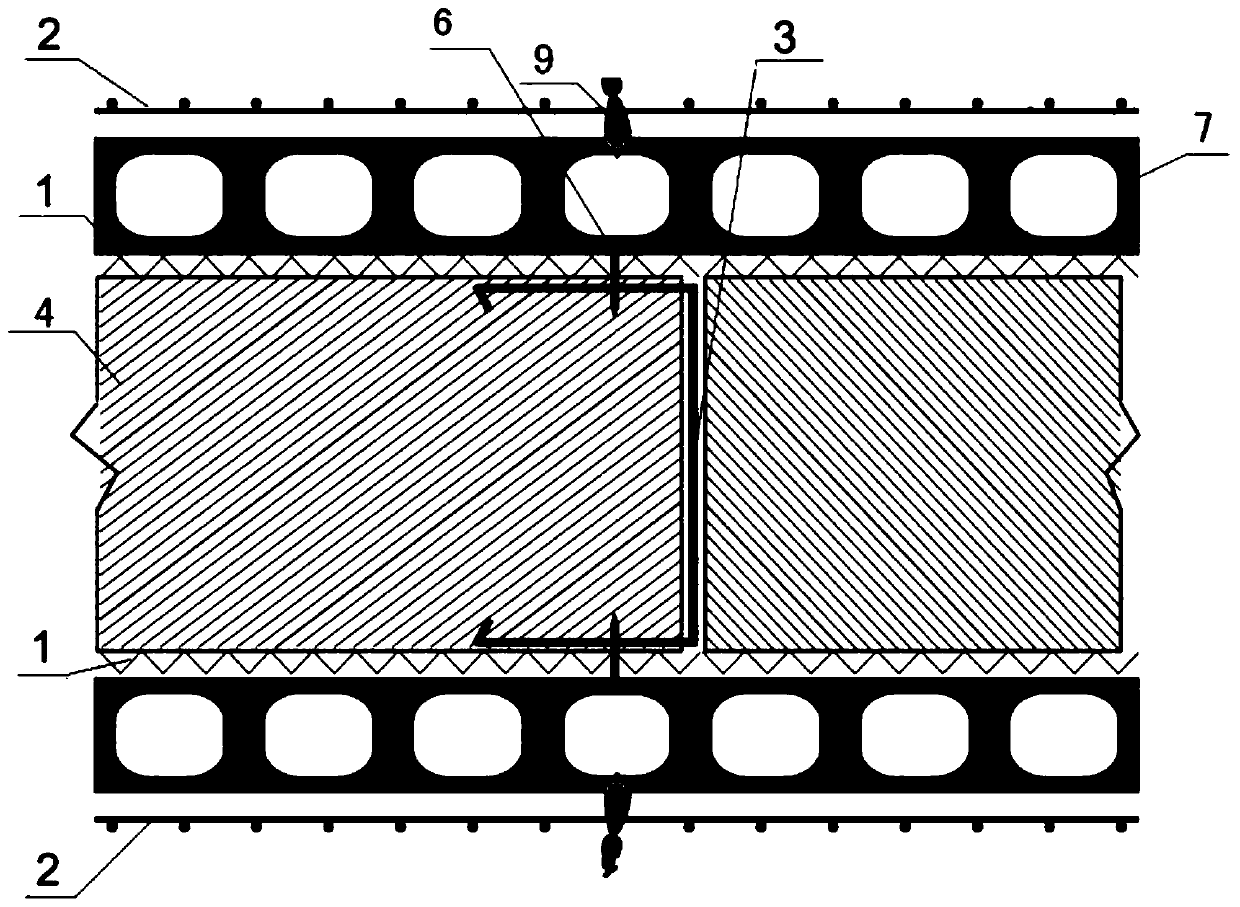

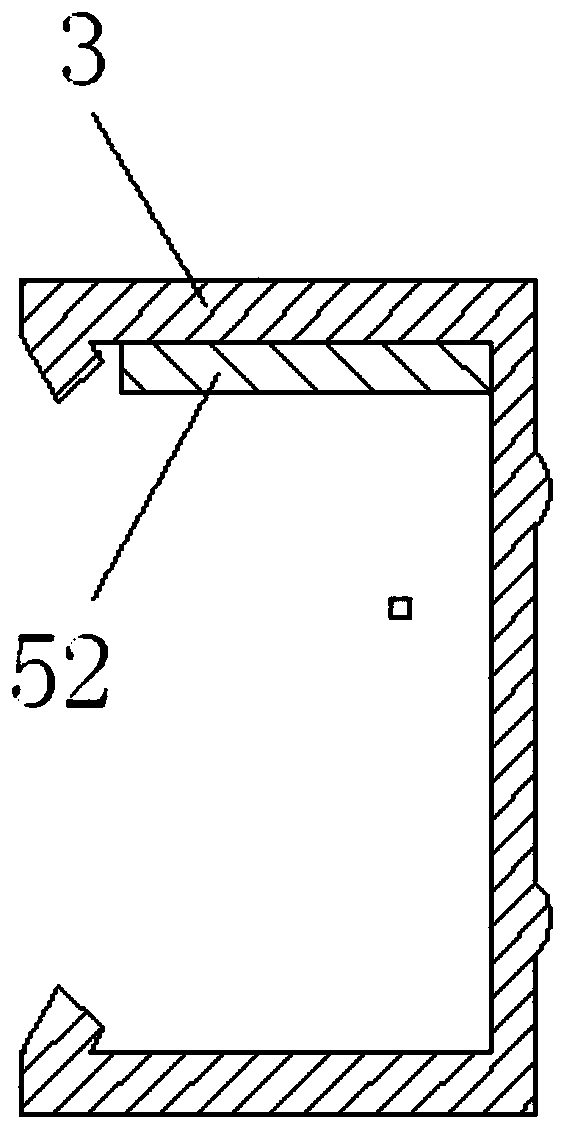

[0025] Such as figure 1 As shown, a whole sprayed wall structure with inner and outer molds, including steel mesh and leaf wall, the steel mesh is used as parallel inner mold 1 and / or outer mold 2, two inner molds 1, two The outer mold 2 is respectively located on both sides of the inner mold 1, and a light steel keel skeleton 3 connected with the inner mold 1 is arranged between the inner mold 1, and the two ends of the light steel keel skeleton 3 are assembled and connected with the structural beam through a connector; A partition is arranged between the inner mold 1 and the outer mold 2 and the three are fixedly connected. The outer mold 2 has a mesh, and the leaf wall material is sprayed on the outer mold 2 to form a leaf wall, and the leaf wall material passes through the outer mold The meshes of 2 connect and cover the inner mold 1. In this embodiment, the inner mold 1 is a dense steel mesh, the outer mold 2 is a medium mesh steel mesh, and the leaf wall material is soli...

Embodiment 2

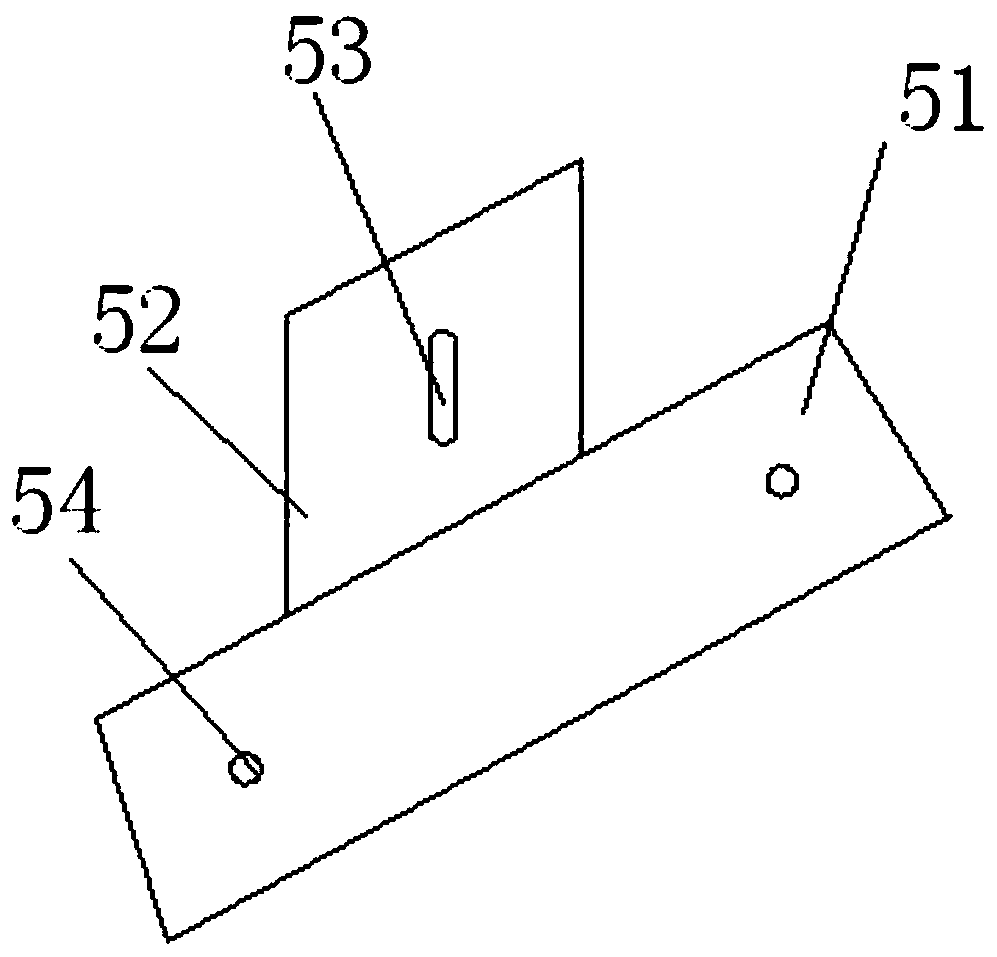

[0029] Embodiment 2: The components included in this embodiment, the structure of each component and the relationship between the components are basically the same as those in Embodiment 1, except that Figure 5 , Figure 6 As shown, the separator is a plurality of concave pads 8 distributed, the bottom surface of the concave pads 8 is closely connected to the inner mold 1, and the two sides of the concave pads 8 are provided with holes 81. An outer edge of both sides of the spacer 8 is provided with a semicircular notch 82, which is convenient for the iron wire 9 to pass through and connect the concave spacer 8 with the outer mold 2. Adopting the concave spacer 8 as a separator is more material-saving and more efficient. An embodiment that is conducive to the filling of the leaf wall material. In this embodiment, the inner mold 1 is a lightweight board, and the space between the two inner molds 1 is hollow. The outer mold 2 is a stretched steel mesh or a welded steel mesh. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com