Drilling fluid circulating system

A technology of circulation system and drilling fluid, which is used in earth-moving drilling, flushing wellbore, wellbore/well components, etc., and can solve the problems of assistant driller's personal safety threat, slow opening speed, influence of mud flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

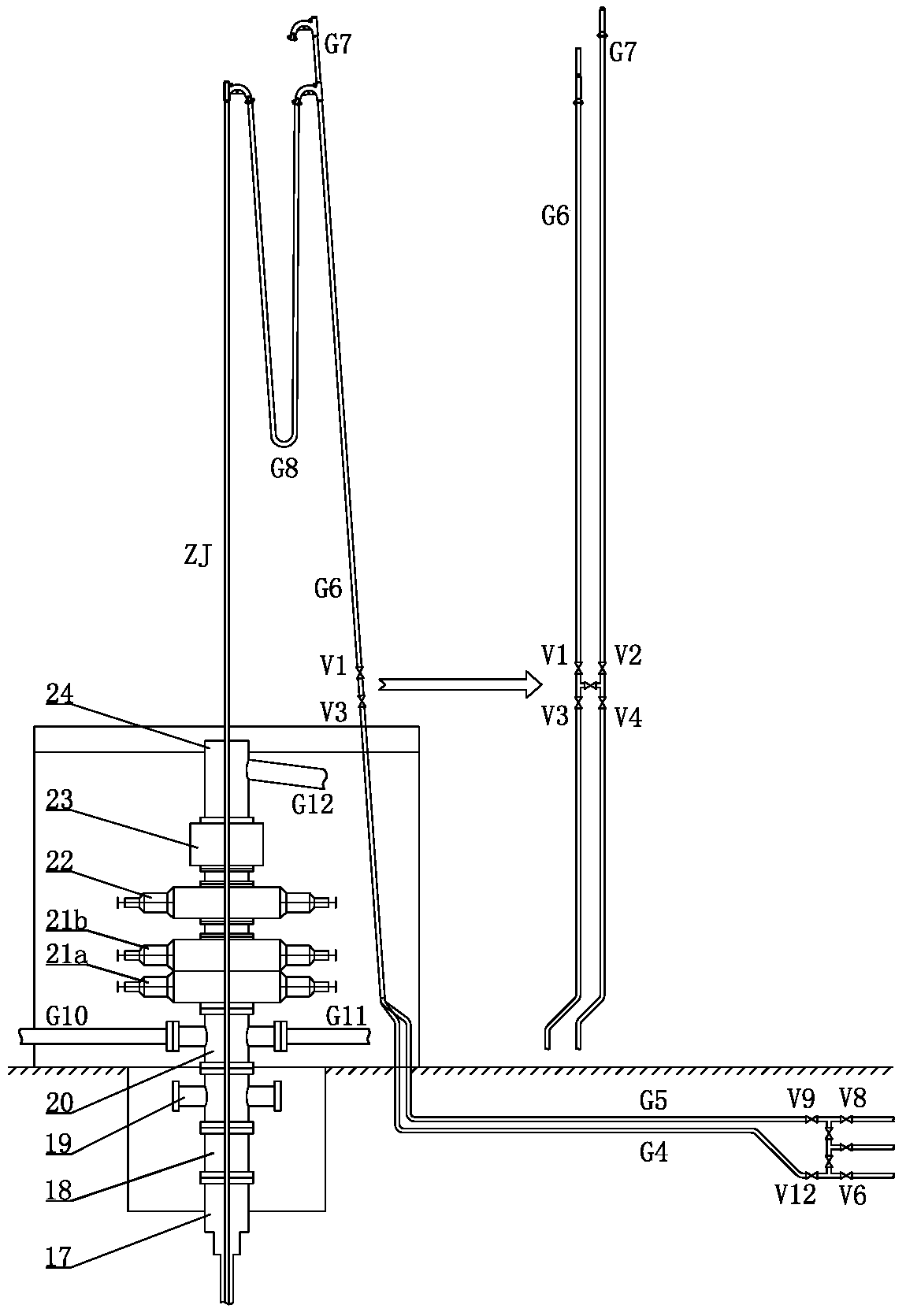

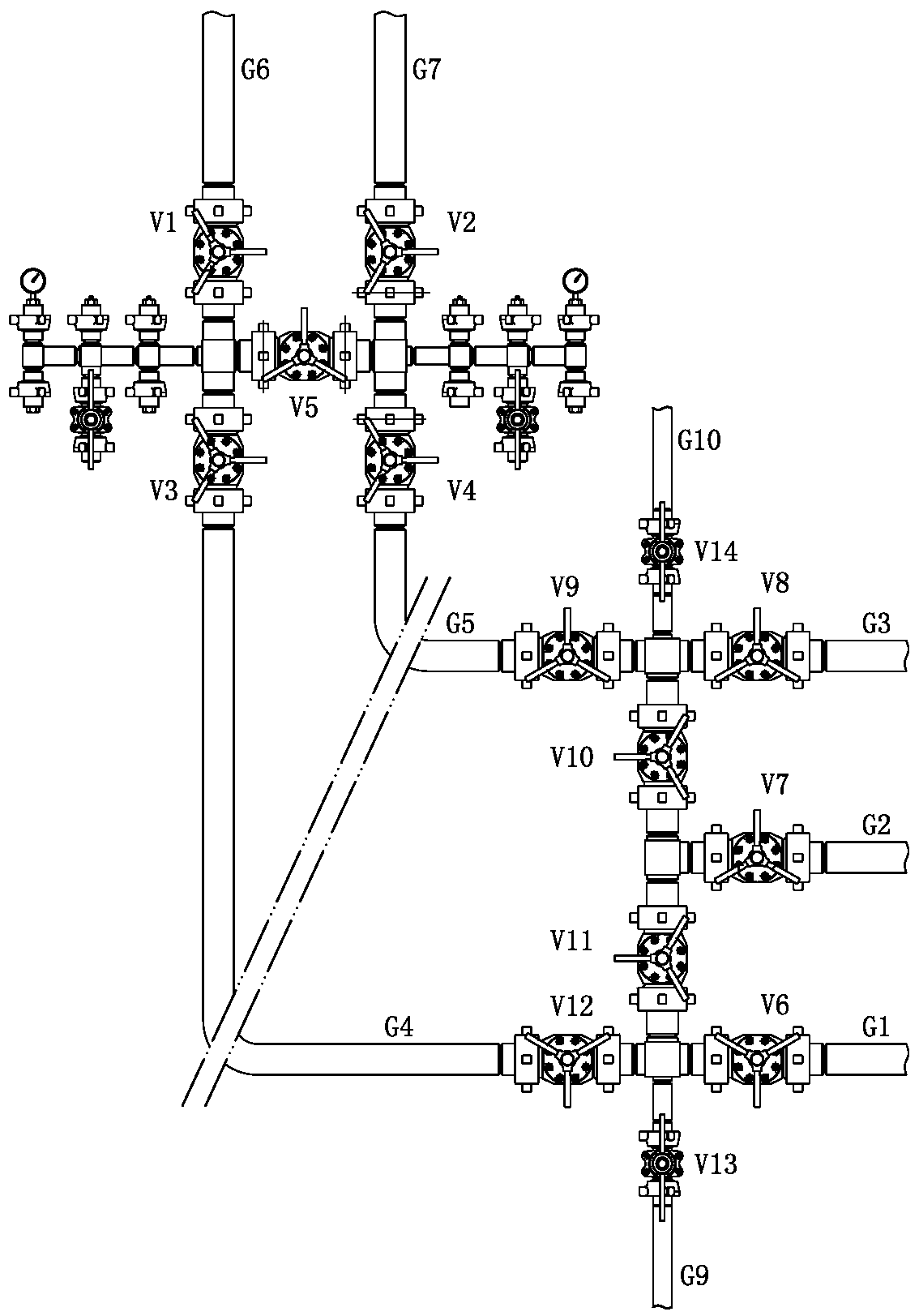

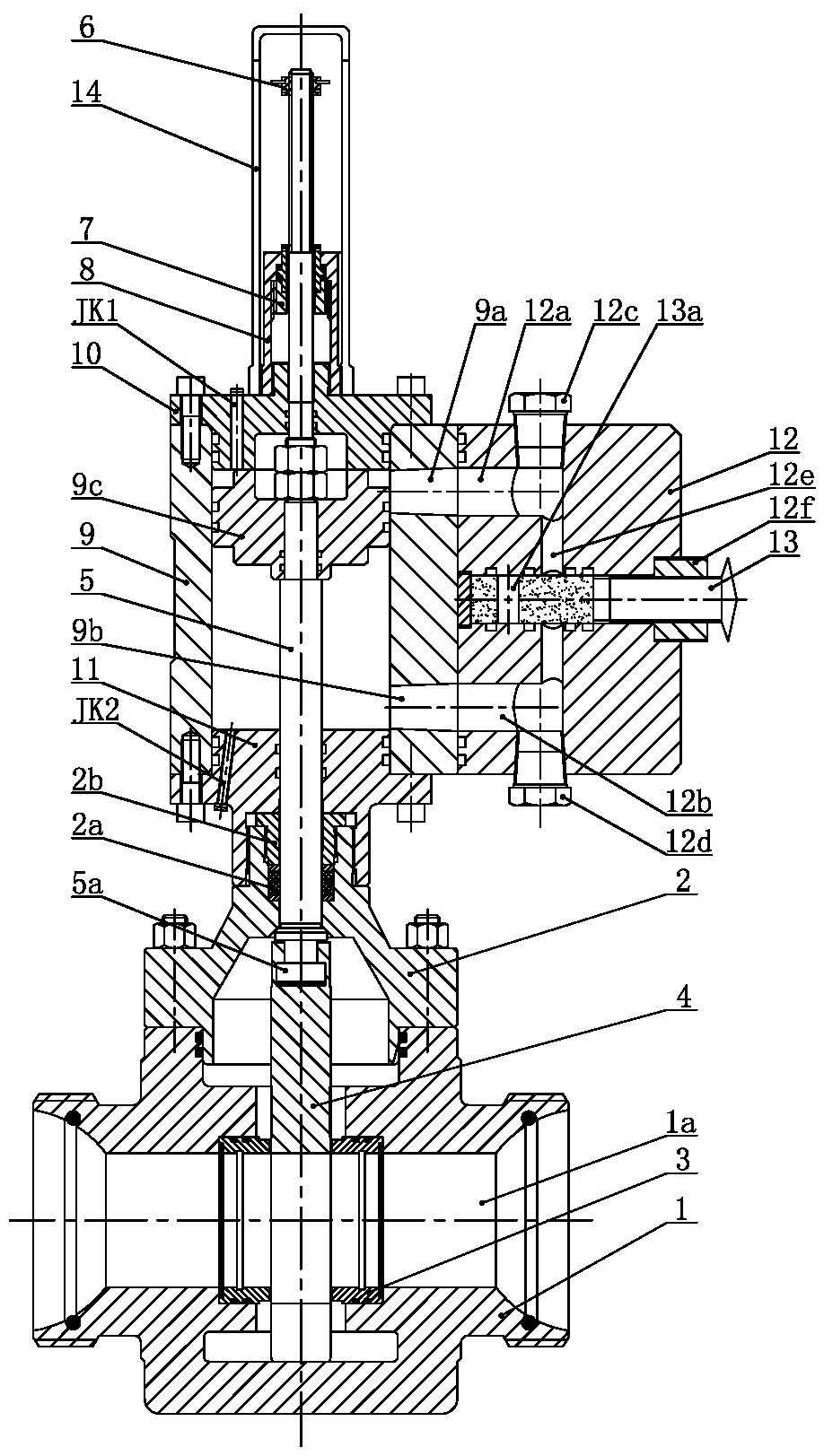

[0037] like figure 1 and figure 2As shown, the drilling fluid circulation system of the present invention includes a drill floor valve group and a surface valve group, the drill floor valve group includes valve one V1 to valve five V5, valve one V1 and valve three V3 are connected in series in the low riser G6 and valve one V1 is on the top, valve two V2 and valve four V4 are connected in series in the high riser G7 and valve two V2 is on the top, there is a low riser bypass port between valve one V1 and valve three V3, valve two V2 and valve four V4 There is a high riser bypass port between them, and the low riser bypass port is connected to the high riser bypass port through valve five V5; the ground valve group includes valve six V6 to valve twelve V12, and the No. 1 pump outlet pipe G1 is in turn Through valve six V6 and valve twelve V12, it is connected with the right ground pipe G4, and the outlet of the right ground pipe G4 is connected with the lower end of the low r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com