Multifunctional mobile test device

A test device and multi-functional technology, applied in the mechanical field, can solve the problems of test personnel and laboratory equipment danger, difficulty in placement process, and influence on test results, so as to improve test efficiency and accuracy, shorten test time, and reduce manpower resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

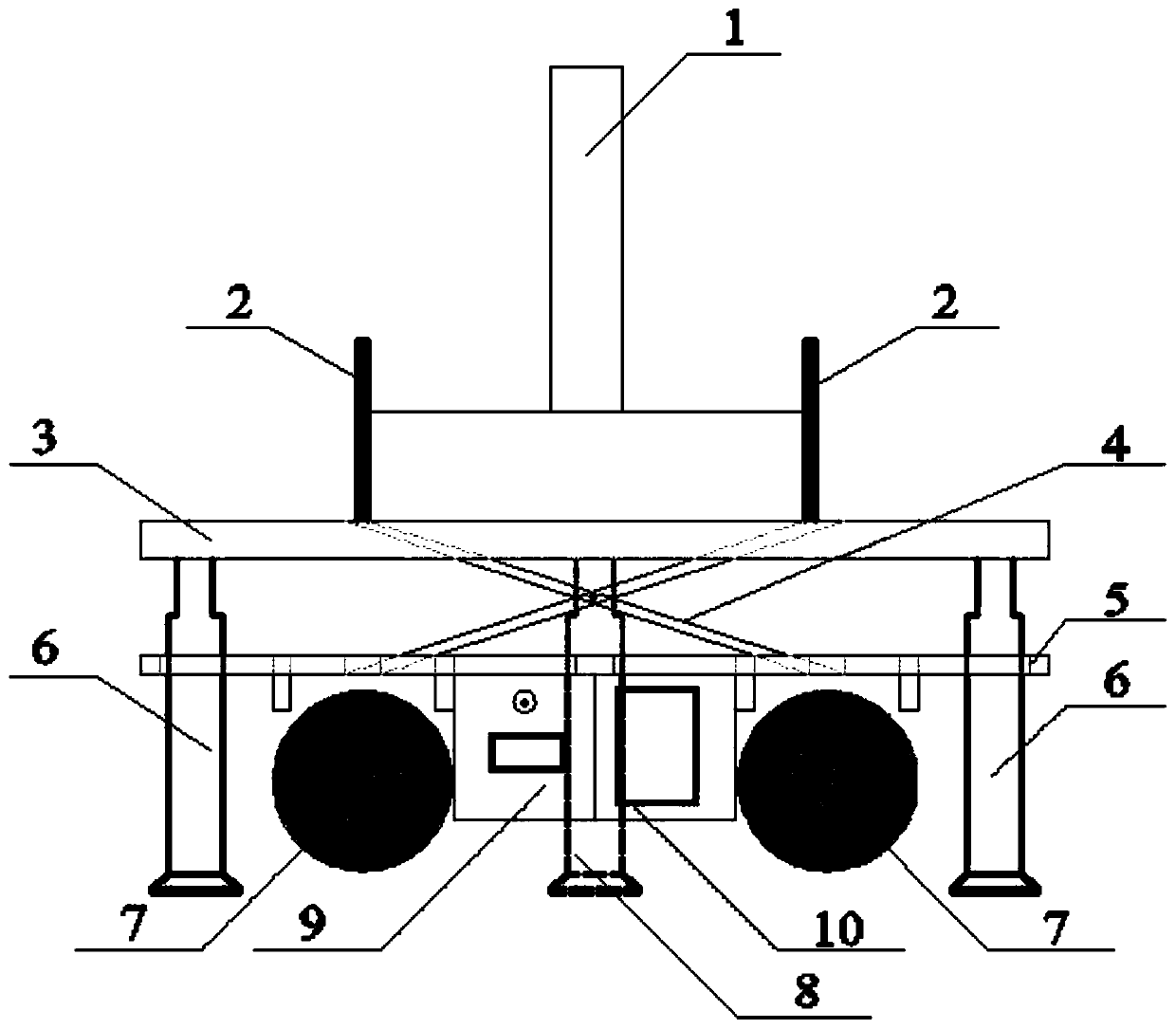

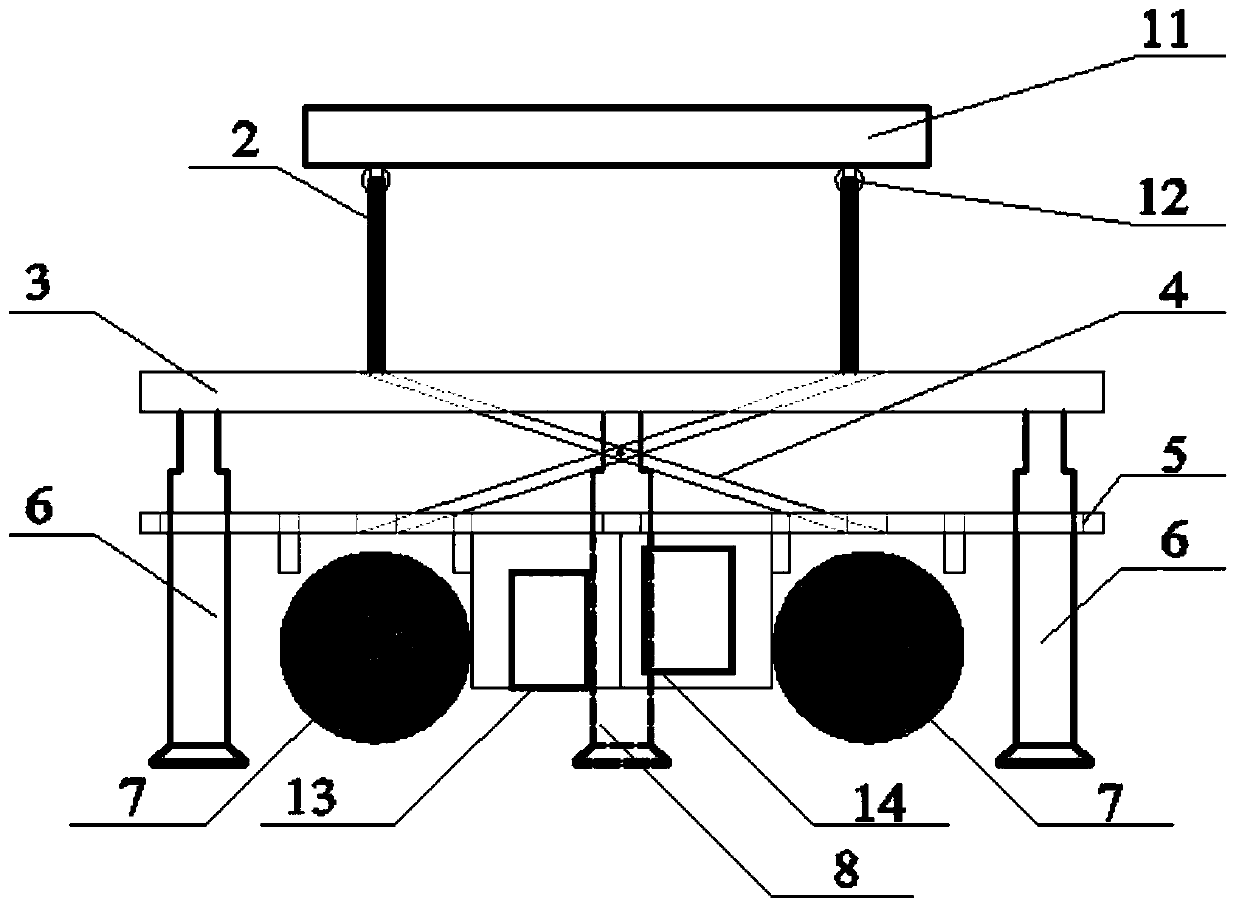

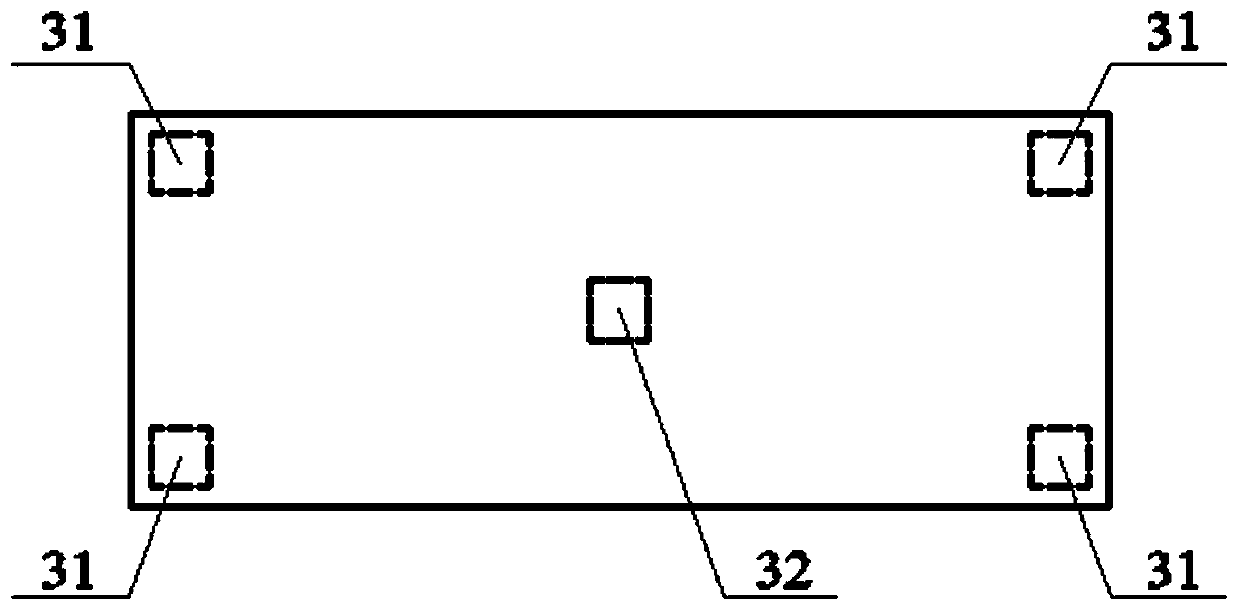

[0030] see Figure 1-10 Describe this embodiment, a multifunctional mobile test device, which includes a mobile splint 2, a lifting plate 3, a scissor support hydraulic mechanism 4, a chassis 5, a corner jack 6, a moving mechanism, a middle jack 8, a fuel tank 9, and a hydraulic control device 10. Battery 13 and signal control device 14, the lower part of the chassis 5 is provided with a moving mechanism, the upper part of the chassis 5 is connected to the lifting plate 3 through the scissors support hydraulic mechanism 4, and the four corners of the lifting plate 3 are respectively provided with corner jacks 6 , the center of the lifting plate 3 is connected to the middle jack 8, the upper part of the lifting plate 3 is provided with a track 42, the number of the moving splint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com