Artificial turf system

A technology of artificial turf and buffer layer, which is applied in textiles and papermaking, roads, buildings, etc., can solve the problems of reduced shock absorption capacity, difficult recycling of artificial turf systems, and increased cost, and achieves the effect of easy recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0164] 1. Materials

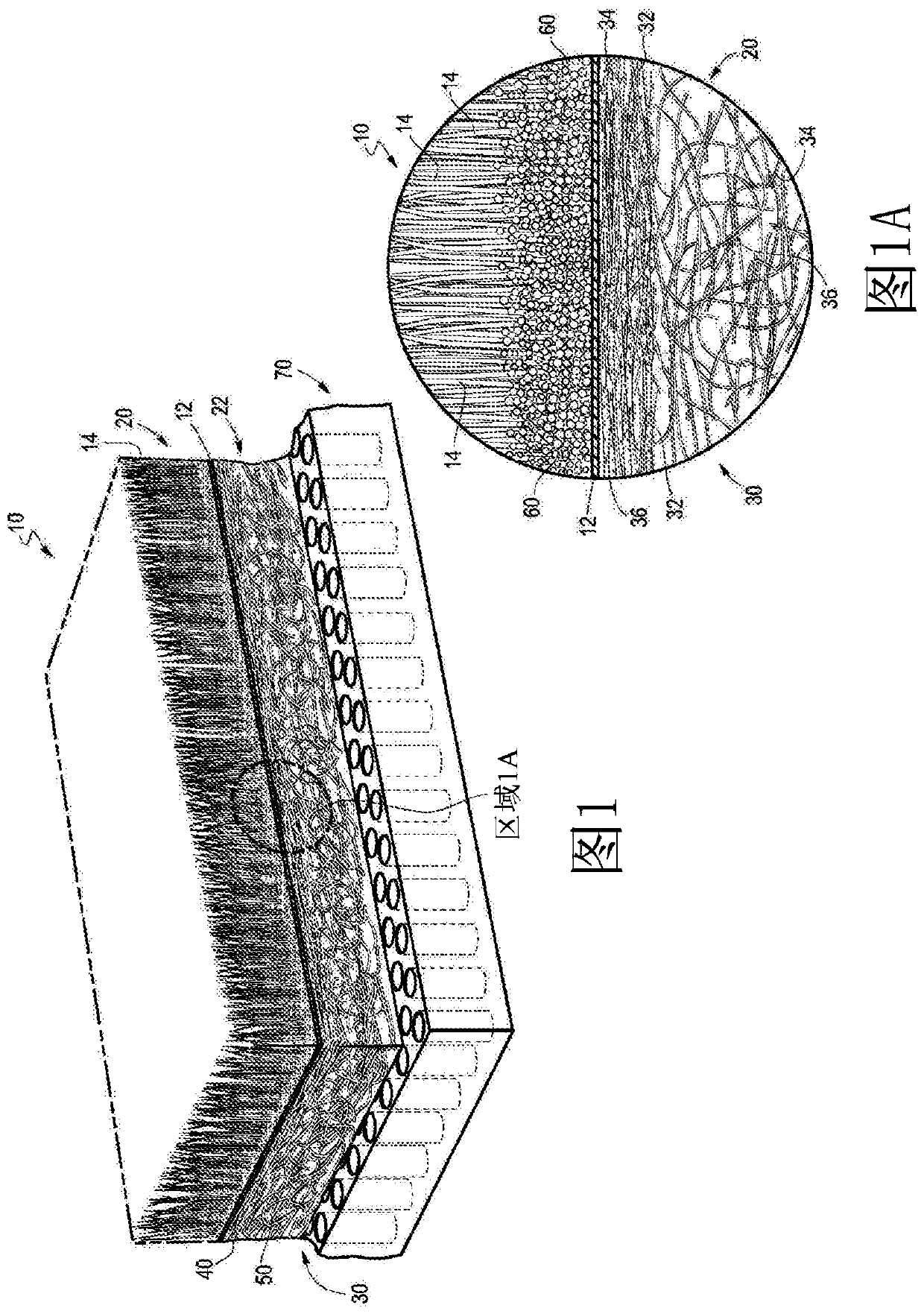

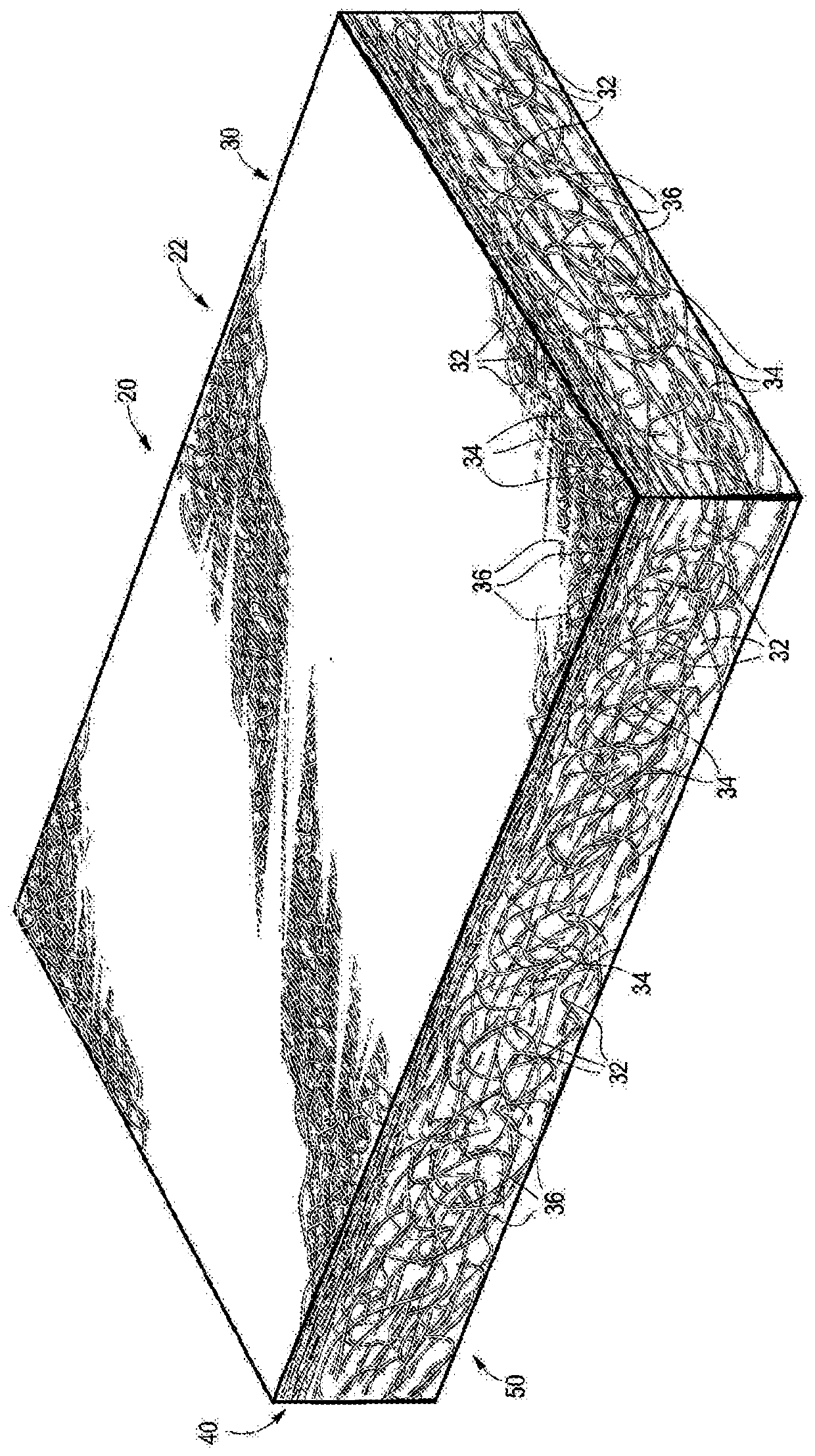

[0165] A shock absorbing assembly with a cushioning layer integrated with a shock absorbing pad was produced on the C-ENG line (Duralastic, US). The formant damper assembly has figure 2 The structure of the shock-absorbing assembly 20 is shown, and the shock-absorbing assembly 20 has a buffer layer 40 and a shock-absorbing pad 50 . The 3DRLM of the formant shock absorber assembly is a continuous fiber composed of ethylene / octene alpha-olefin copolymer with a density of 0.905 g / cc.

[0166] Table 1 below provides the characteristics of the formant damper assembly (hereinafter referred to as SAC1).

[0167] Table 1 - SAC1 Characteristics

[0168] Nominal size = 305mm × 305mm × 54mm

[0169] SAC1

[0170] sample mass (g) Thickness (mm) Volume (cc) Density(g / cc) Porosity(%) Shock absorbing components 310.1 54 5016.8 0.0618 93.17% Cushion 187.9 48 4459.3 0.0421 95.34% The buffer layer 122.2 6 557.4 0.2192 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap