Dust removal device for machining

A dust removal device and mechanical processing technology, applied in the field of mechanical processing, can solve problems that affect the safety of the working environment, affect the safety of the worker's respiratory tract, and affect the health of the worker, and achieve the goal of enhancing environmental protection, improving safety, and facilitating recycling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

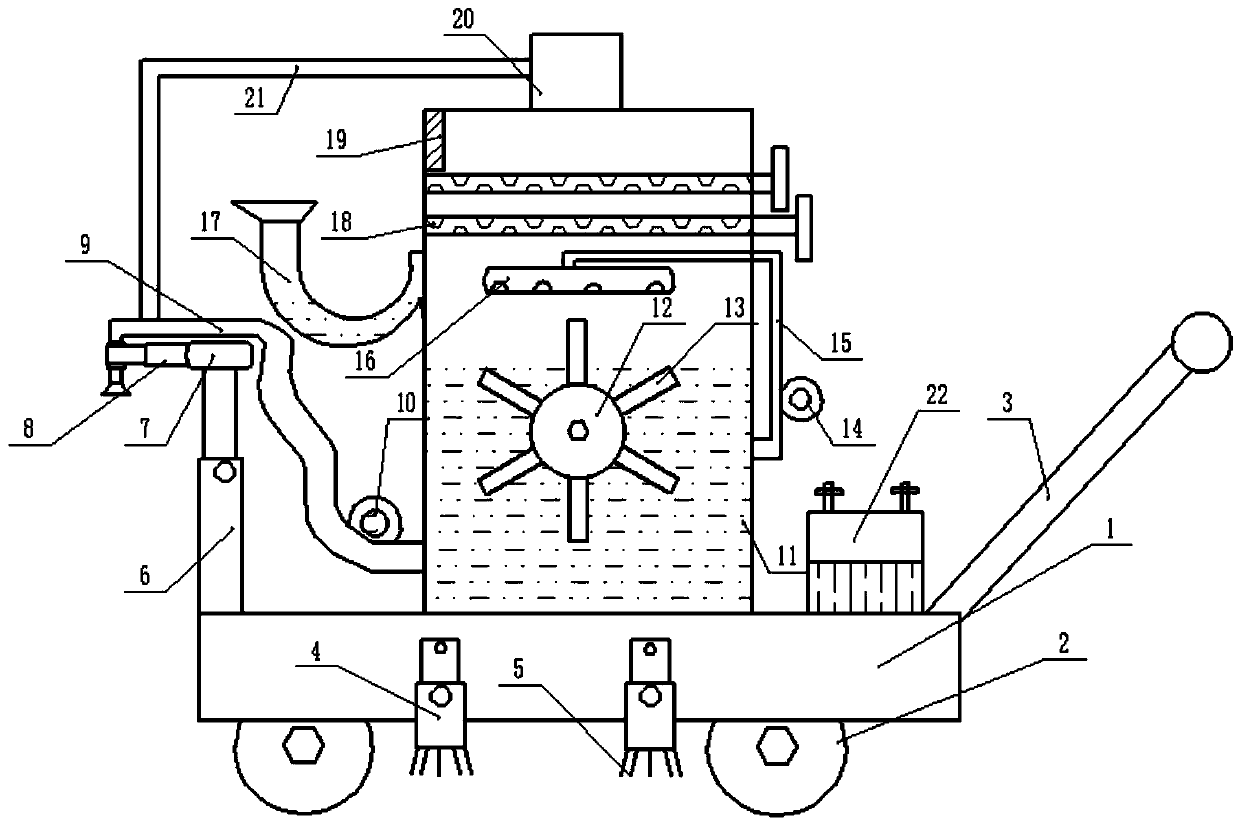

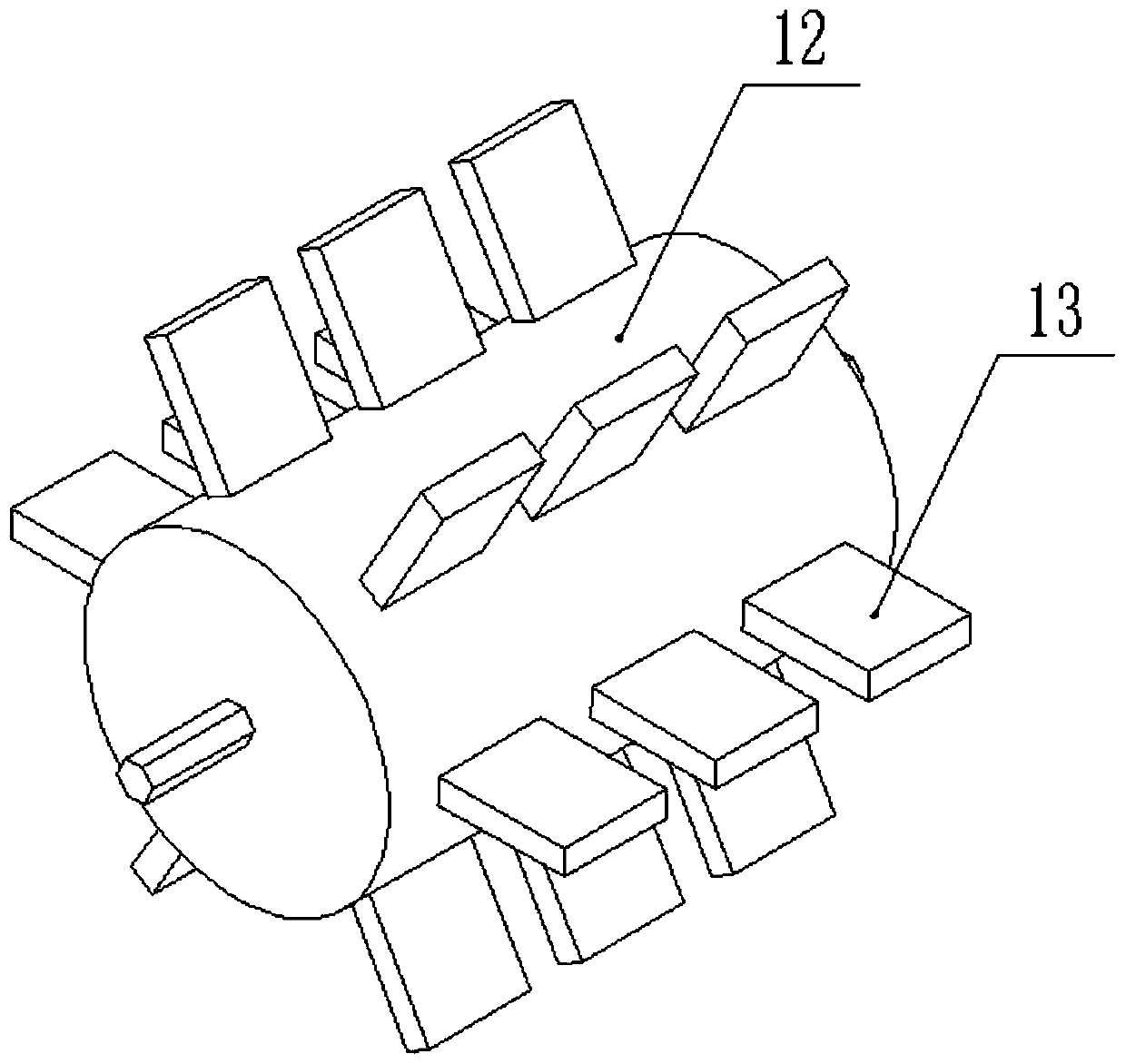

[0020] Example 1: Please refer to Figure 1-3 , a dust removal device for mechanical processing, including a base 1 and a filter box 11, the bottom of the base 1 is provided with a guide wheel 2, the base 1 is provided with a push handle 3, the push handle 3 facilitates the direction of movement of the control device, and the guide wheel 2 It is convenient to ensure the movement of the device, which is beneficial to the use of the device at various positions, and is beneficial to the collection of fine chips generated during different mechanical processing, which is convenient for its subsequent centralized processing and convenient use. At the same time, the whole device is moved to make it convenient to replenish water in the filter box 11, to facilitate the filtering, and to facilitate the concentrated discharge of the collected fine dust particles, which is convenient for subsequent recycling and convenient use.

[0021] The upper surface of the base 1 is provided with a f...

Embodiment 2

[0028] Embodiment 2: On the basis of Embodiment 1, the side wall of the base 1 is provided with a vertical telescopic column 4, and the bottom end of the vertical telescopic column 4 is provided with a fixed claw 5. Adjust the vertical telescopic column 4 to make the fixed claws 5 tightly grasp the ground, ensure the stability of the device, avoid device sliding, improve the safety of the device, and facilitate dust removal during machining, which is convenient for use.

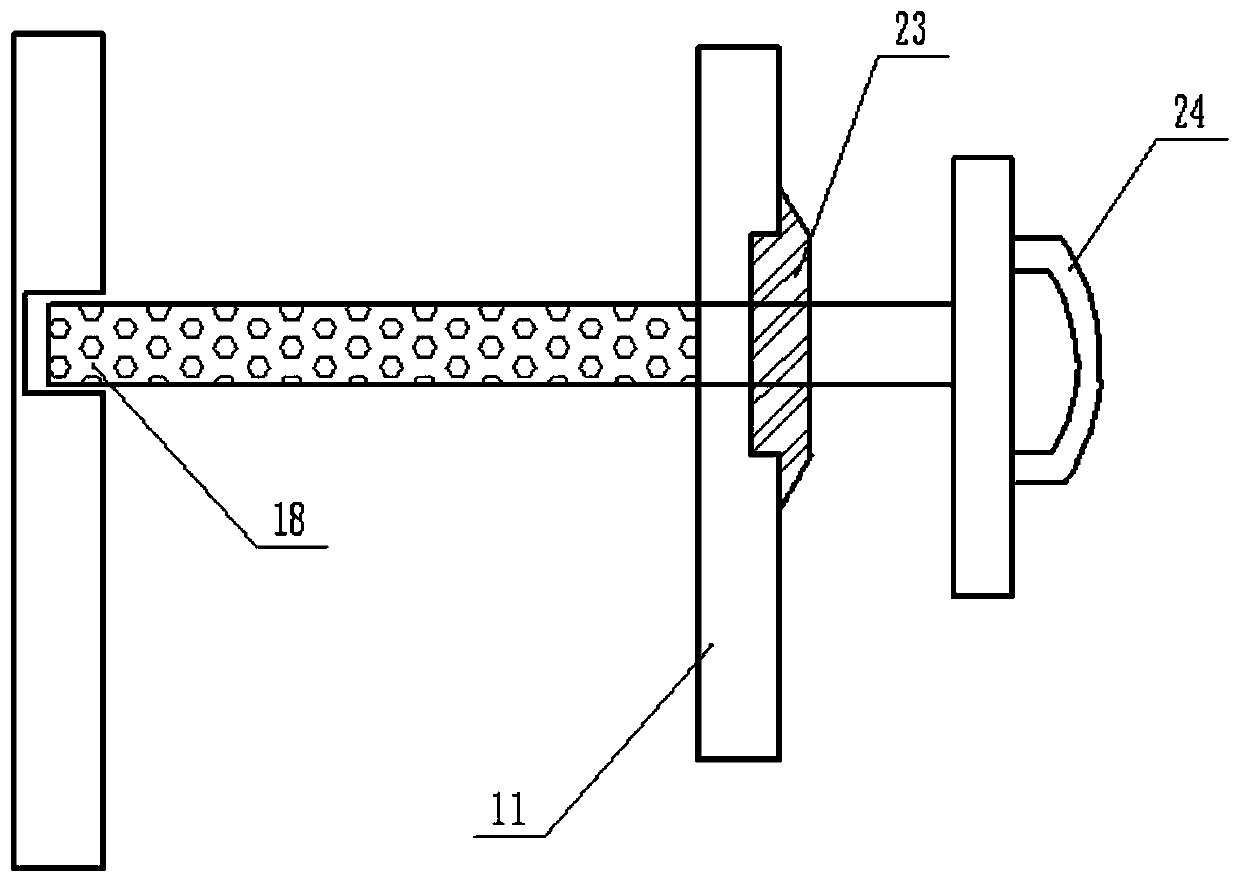

[0029] The side wall of the filter box 11 is provided with a water inlet elbow 17, and a control valve is arranged on the water inlet elbow 17. The water inlet elbow 17 is convenient to replenish the water in the filter box 11 in time, which is beneficial to the water filtration. Close the control valve on the water inlet elbow 17, the remaining water at the bottom of the water inlet elbow 17 increases air tightness, improves the effect and efficiency of machining dust treatment, and is convenient to use.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com