Construction process of rigid waterproof roofing

A rigid waterproofing and construction method technology, applied in the direction of roofing, building, building structure, etc., can solve the problems of the rigid waterproofing roof not reaching the waterproofing effect, aging and becoming brittle, losing, and the rigid waterproofing layer leaking water, etc., to avoid dry shrinkage. Cracks and evaporative cracks, improved water resistance, reduced width effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

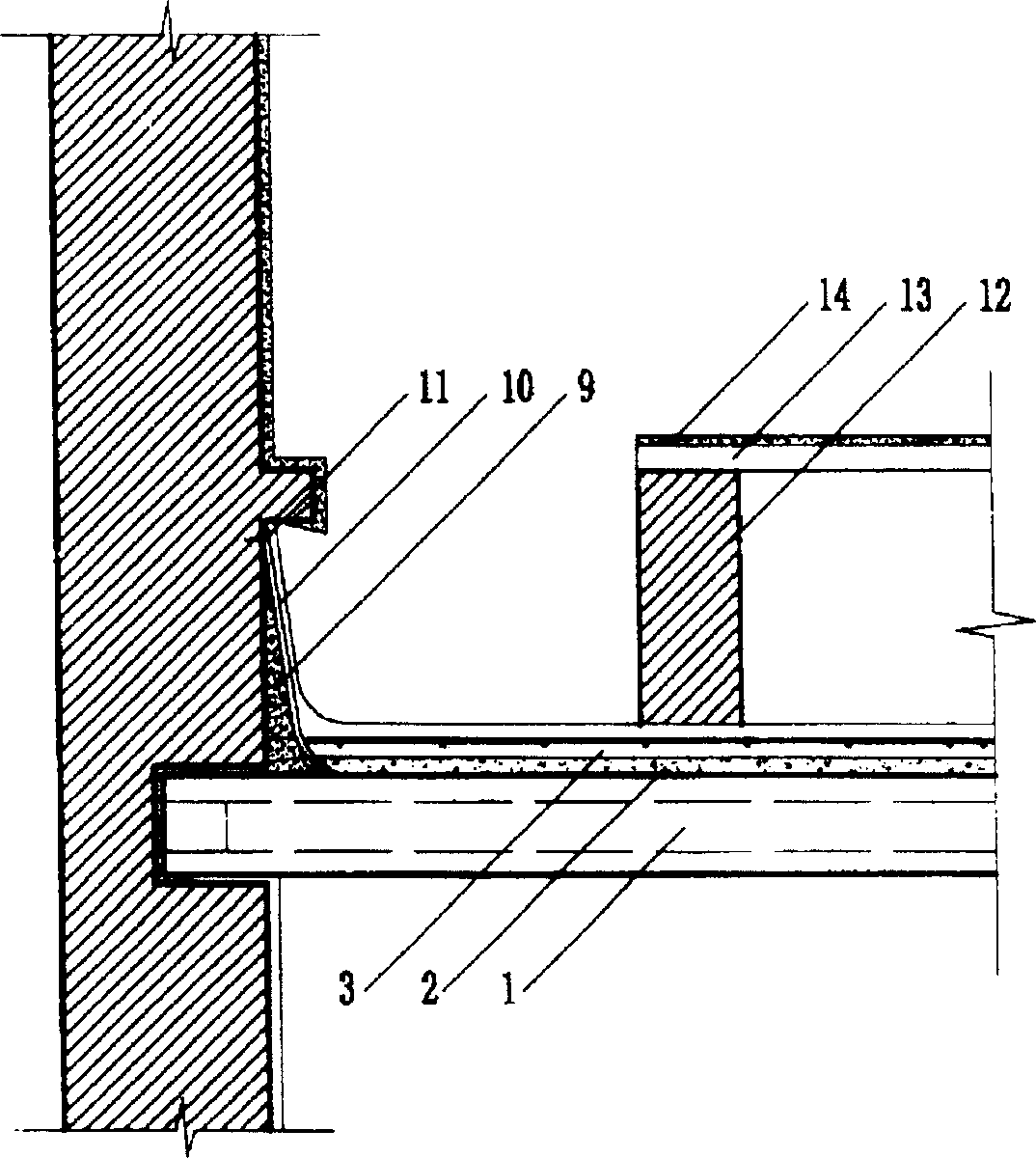

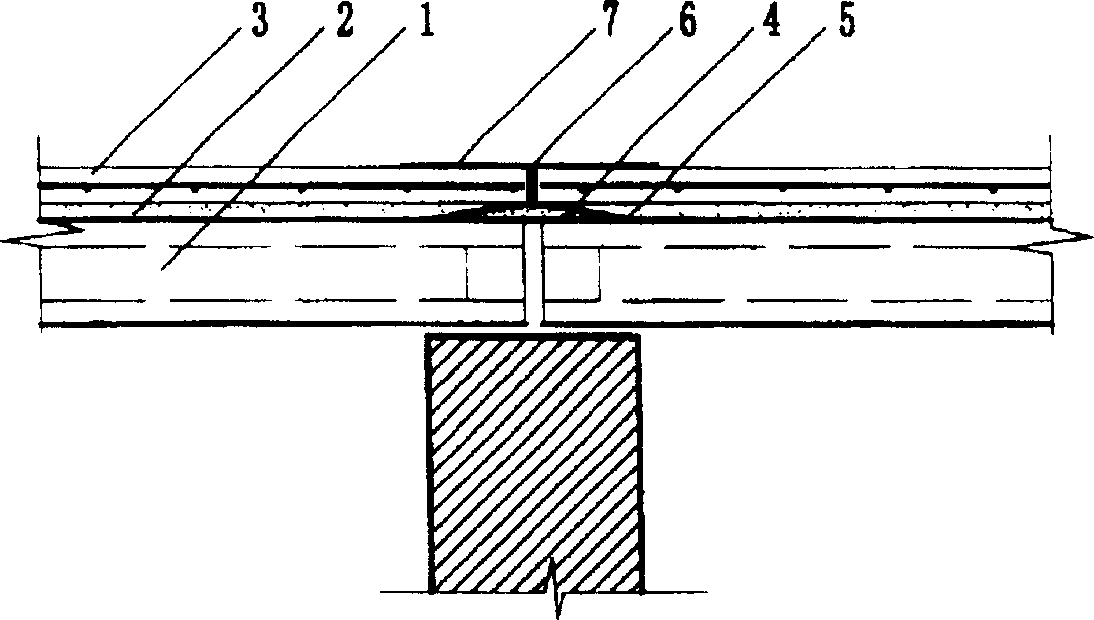

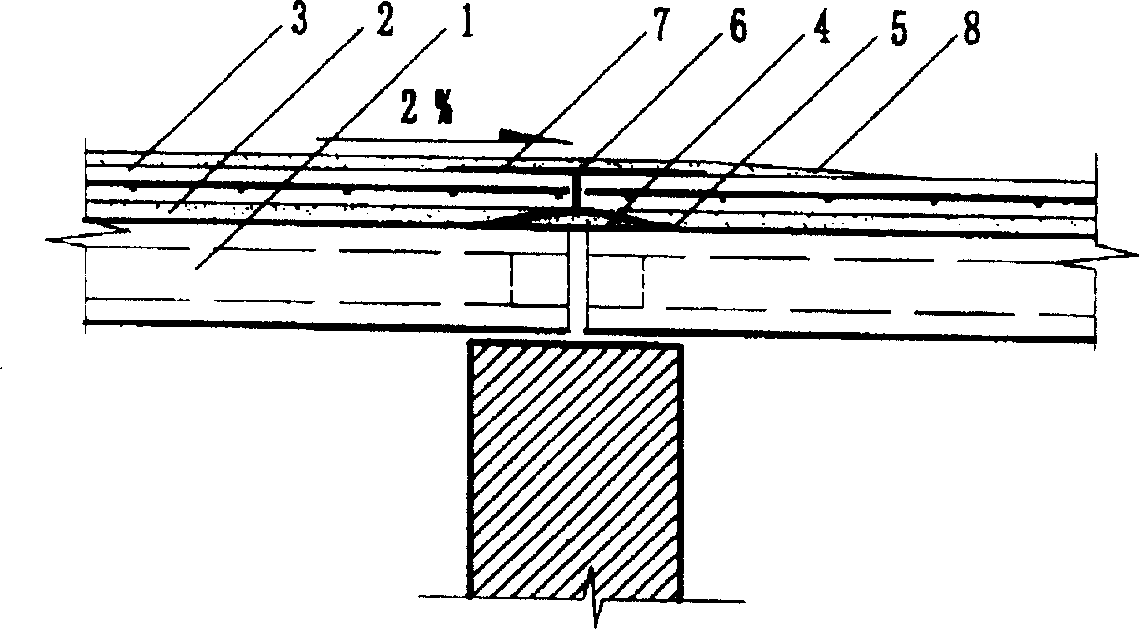

[0029] Referring to the accompanying drawings, it can be seen that a concrete construction method of a rigid waterproof roof is as follows:

[0030] 1. At the expansion joints 15, 16, 17, and 18 of the rigid waterproof layer reserved for the roof panel 1, use 1:2 cement mortar to form a 300mm wide arc 4, and then stick it with a 330mm wide linoleum 5 ; Use 1:2 cement mortar to form a tile shape 9 at the flashing place where the roof panel 1 is connected to the parapet wall, and then stick it on it with linoleum 10. Cement mortar, linoleum joint lap should preferably be greater than 50mm.

[0031] 1. Then lay a 1:3 lime or yellow mud mortar cushion 2 on the roof panel 1, and its thickness is 20mm;

[0032] 2. On the lime or yellow mud mortar cushion layer 2, pour the first C20 waterproof concrete rigid waterproof layer 3 in separate boxes, and then after its strength reaches 1.2MPa, dry paste 40mm at expansion joints 15, 16, 17, and 18 Two layers of high linoleum strips 6; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com