Shrinkage-reducing type concrete high-efficiency water reducing agent

A high-efficiency water reducer and concrete technology, which is applied in the field of concrete admixtures, can solve the problems of exacerbating the risk of concrete cracking, the difficulty of expanding the expansion agent, and the uncertainty of the expansion agent, achieving good shrinkage resistance, reducing shrinkage, and good adaptability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

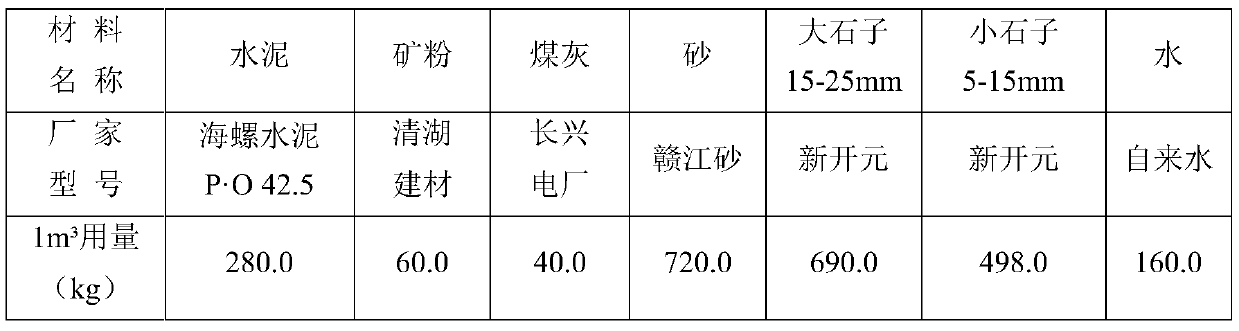

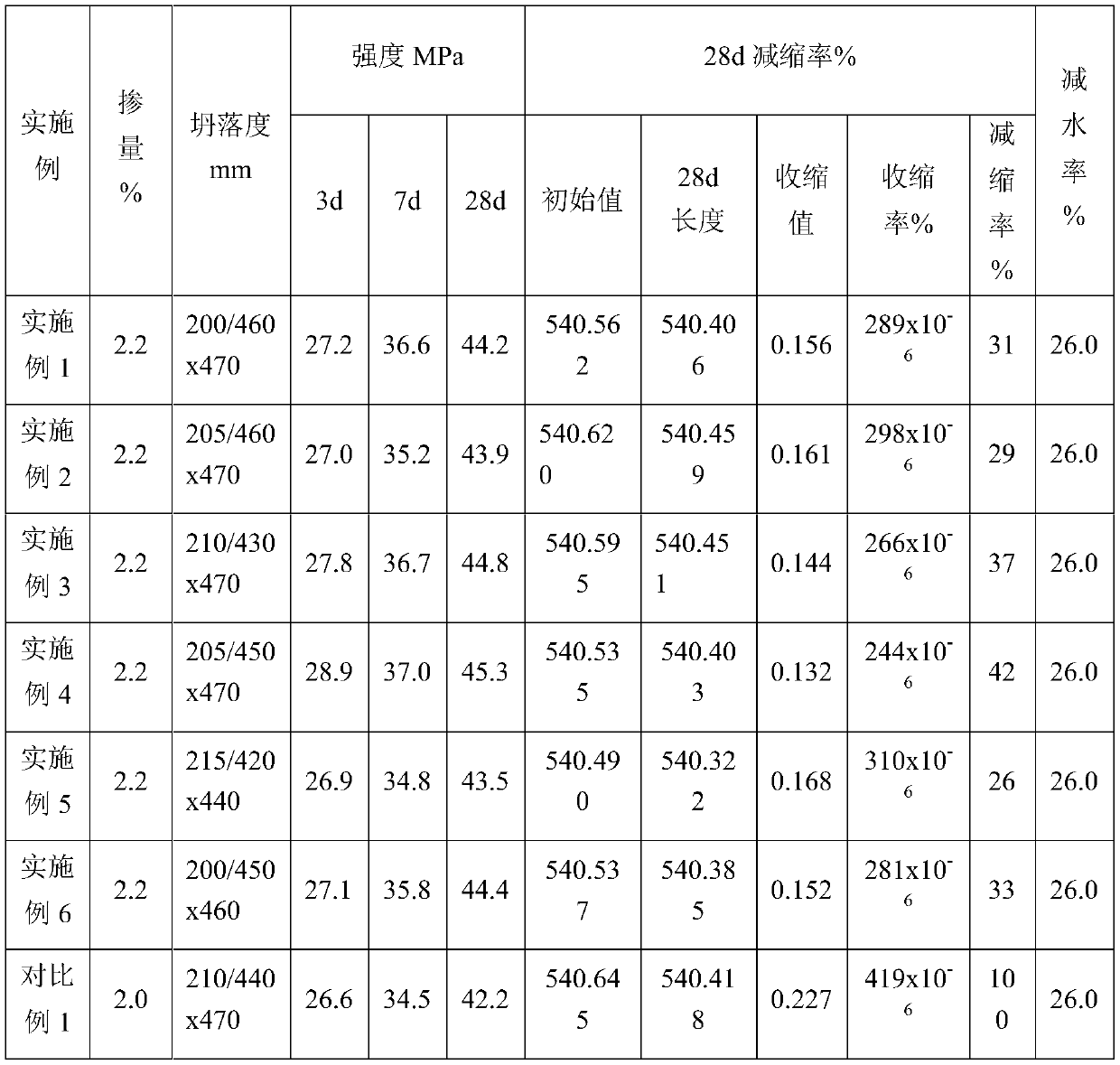

Method used

Image

Examples

Embodiment 1

[0027] This embodiment is composed of the following components according to weight percentage: 87.3% of naphthalene-based high-efficiency water reducer, 8.2% of polyethylene glycol, 2.5% of neopentyl glycol, and 2.0% of xanthan gum.

[0028] After weighing each component according to the number of parts by weight, first add 87.3% of naphthalene-based high-efficiency water reducer into the reactor, heat it to 50-60°C, and then add the shrinkage-reducing component polyethylene glycol 8.2 every 10-15 minutes. % and neopentyl glycol 2.5% until completely dissolved, maintain the temperature of the reactor at 50-60°C, continue stirring for 30 minutes, then cool down to 30-40°C, add 2.0% xanthan gum, the thickening component, and continue stirring for 30 minutes until Cool to room temperature and the product is complete.

Embodiment 2

[0030] The method is basically the same as that of Example 1, except that the raw materials are different. This example is composed of the following components according to weight percentage: 88.1% naphthalene-based high-efficiency water reducer, 9.7% polyethylene glycol, carboxymethyl cellulose 2.2%.

Embodiment 3

[0032] The method is basically the same as in Example 1, except that the raw materials are different. This example is composed of the following components according to weight percentage: 95.0% naphthalene-based high-efficiency water reducer, 3.5% neopentyl glycol, 1.5% xanthan gum %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com