Method for detecting paint film coating uniformity of enameled wire

An enameled wire varnish and detection method technology, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of less enameled wires, enameled wire skew, and reduced testing efficiency, and achieve improved detection efficiency, low use cost, and improved reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The method for detecting the uniformity of enameled wire paint film coating by using the above-mentioned auxiliary tools and equipment includes the following steps:

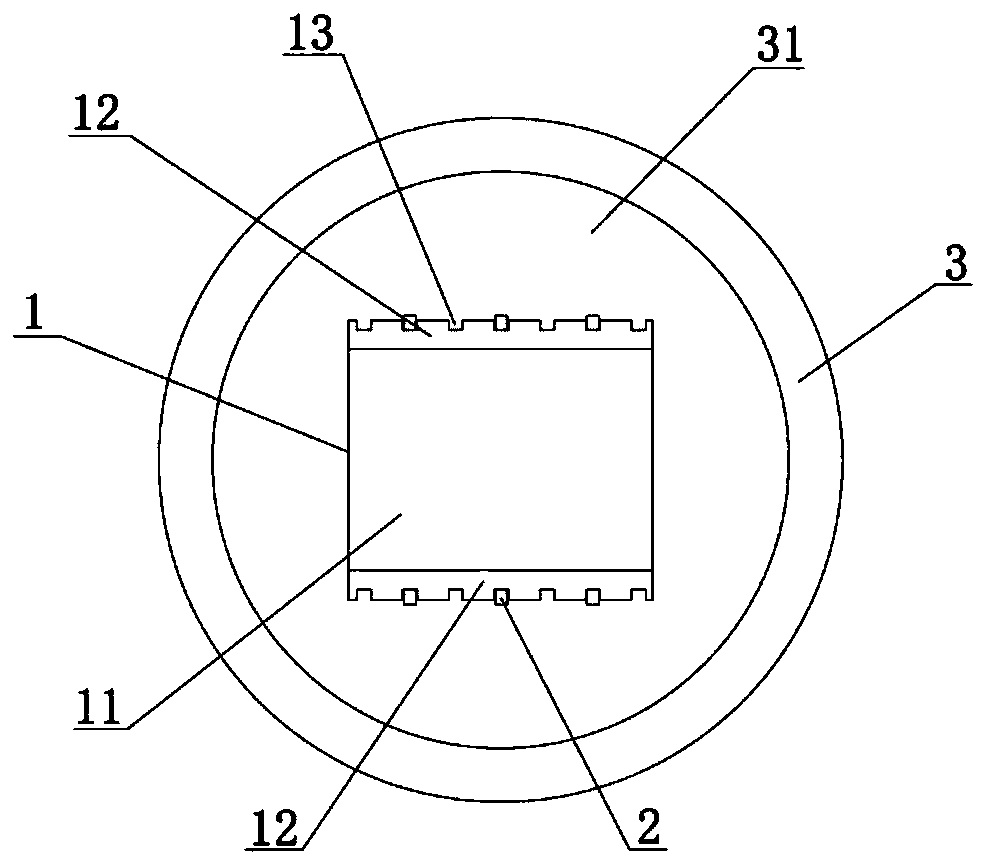

[0038] 1) Cut off the round enameled wire with a tool, cut 8 pieces of single-coated enameled wire with a length of 10mm and a diameter of 0.85mm, type QA grinding and polishing wire sample 2, manually straighten the grinding and polishing wire sample 2 respectively, and then vertically position it at the vertical On the vertical positioning groove 13 on the positioning plate 1, the adjacent grinding and polishing line samples 2 are arranged at intervals, and one end of the grinding and polishing line sample 2 is stretched out from the verticality positioning plate 1 for a certain distance, and the grinding and polishing line sample 2 is held Put the verticality positioning plate 1 into the center of the glue filling space 31 of the forming mold 3 at one end.

[0039] 2) Prepare the cold buried resin powde...

Embodiment 2

[0047] 1) Cut off the flat enameled wire with a tool, and cut off 4 single-coated enameled wires with a length of 10mm and a section length of 4mm and a section width of 1.96mm. Vertically positioned on the vertical positioning groove 13 on the verticality positioning plate 1, the adjacent grinding and polishing line samples 2 are arranged at intervals, and one end of the grinding and polishing line sample 2 is stretched out from the verticality positioning plate 1 for a certain distance, holding the grinding wheel One end of the throwing line sample 2 puts the verticality positioning plate 1 into the center of the glue filling space 31 of the forming mold 3 .

[0048] 2) Prepare the cold buried resin powder and liquid curing agent according to the volume of 2:1, first put the cold buried resin powder into the container, then pour the liquid curing agent into the container, stir evenly until a gel-like solidifying liquid without bubbles is formed , inject the prepared pouring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com