Synchronous belt tooth profile detection system and method based on laser triangulation method

A technology of laser triangulation and detection system, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of accelerated wear, increased transmission noise, and reduced service life of synchronous belts, achieving high reliability and improved fitting Accuracy, test results are scientific and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

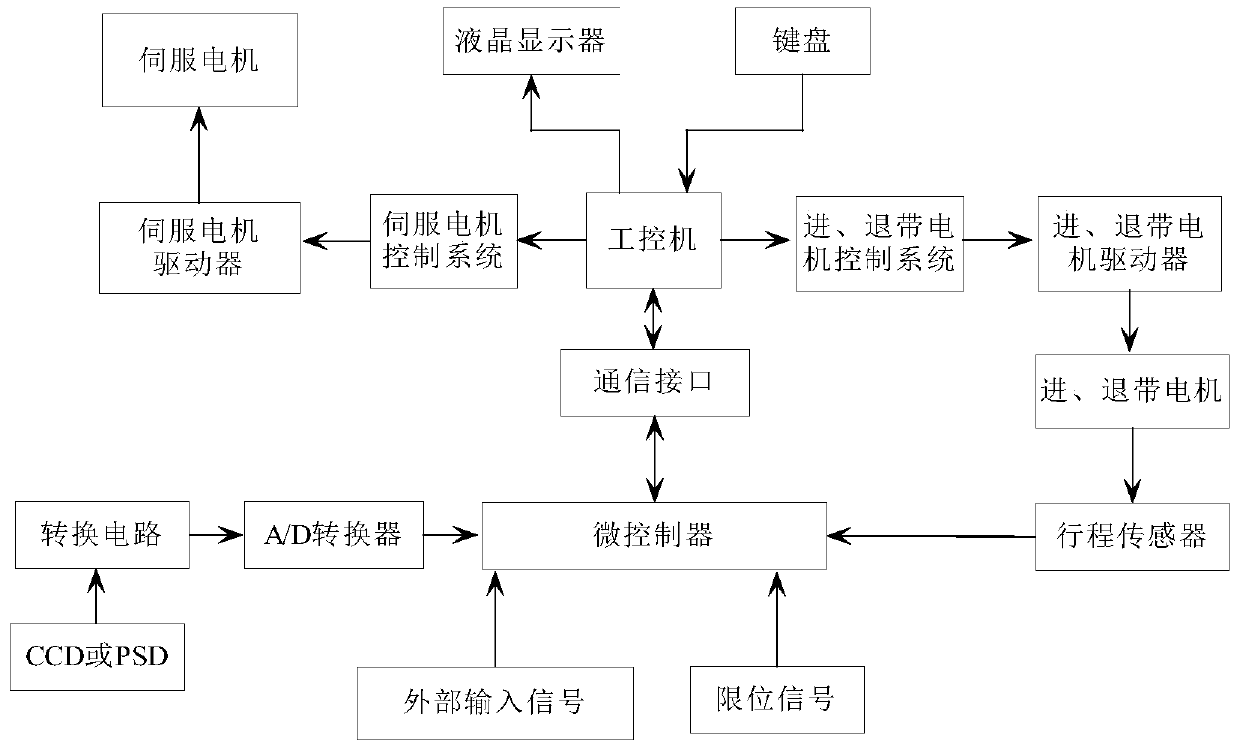

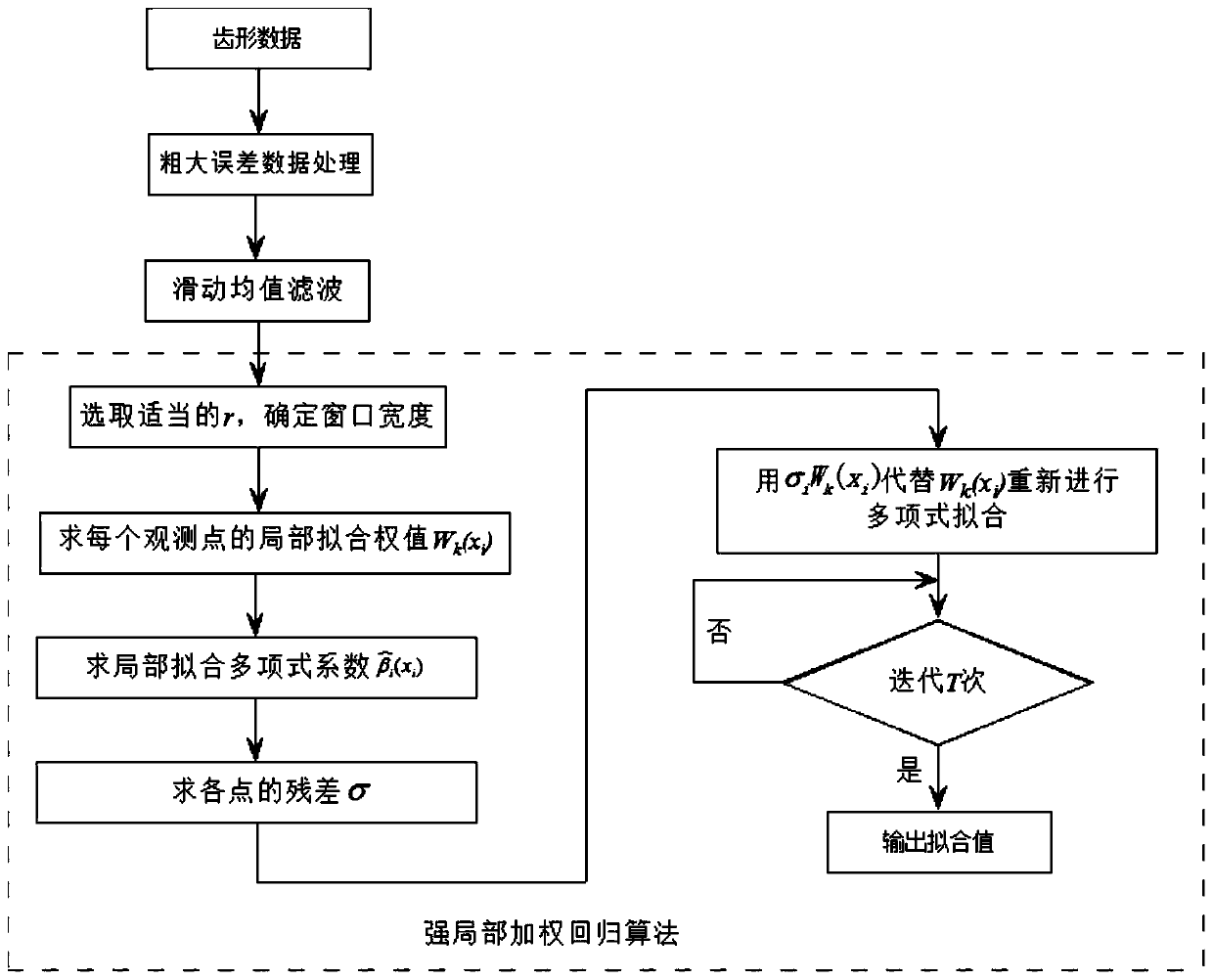

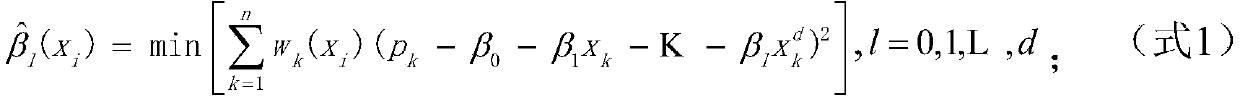

[0040] Please refer to figure 1 , the present embodiment is a synchronous belt tooth shape detection system 100 based on laser triangulation, which includes a microcontroller, a laser displacement sensor communicated with the microcontroller through an A / D converter signal, and the microcontroller The industrial computer that realizes signal communication through the communication interface, the servo motor control system and the advance / reverse belt motor control system that are connected to the circuit of the industrial computer, the servo motor driver that is connected to the circuit of the servo motor control system, and are controlled by the servo The motor driver controls the servo motor that drives the synchronous belt to move, the belt advance / retract motor driver connected to the belt advance / retract motor control system circuit, the belt advance / retract motor controlled by the belt advance / retract motor driver, and the belt advance / retract detection A stroke sensor f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com