Gas monitoring calibration method and system based on linear regression

A linear regression and gas monitoring technology, applied in measuring devices, material analysis through electromagnetic means, instruments, etc., can solve problems such as inability to obtain more accurate component information, mixed interference of various gas factors, and unresponsive impact effects. Achieve the effect of improving the difficulty of calibration, reducing the number of manual maintenance, and improving the accuracy of monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

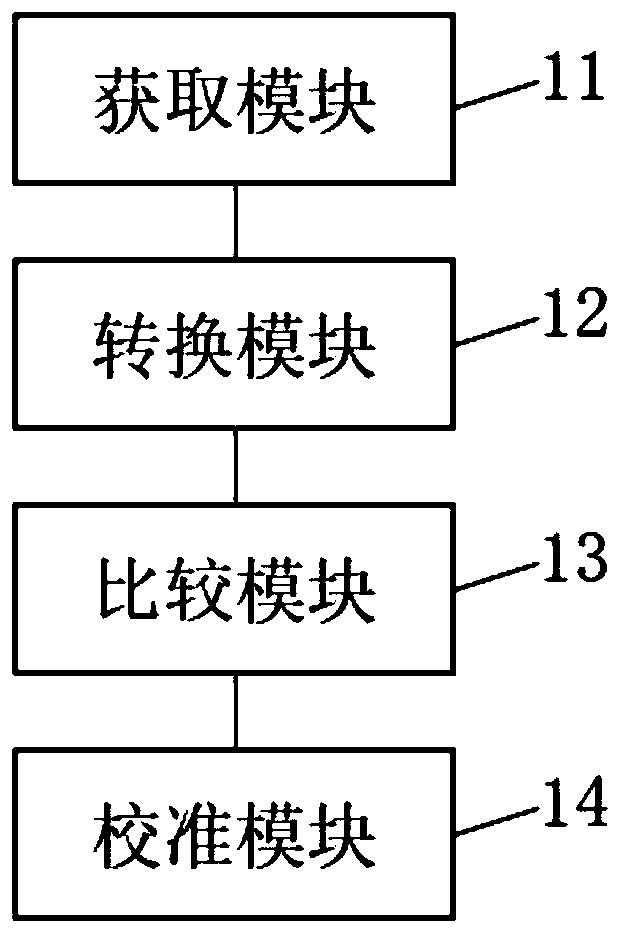

[0047] This embodiment provides a gas monitoring calibration system based on linear regression, such as figure 1 shown, including:

[0048] An acquisition module 11, configured to acquire the gas mixture monitoring value of the environment where the monitoring equipment is located;

[0049] A conversion module 12, configured to convert the obtained mixed monitoring value into a gas component value based on linear regression;

[0050] A comparison module 13, configured to compare the converted gas composition value with the standard source data, and generate a new gas composition value according to the comparison result;

[0051] The calibration module 14 is configured to perform calibration processing on the obtained new composition value to obtain final composition information.

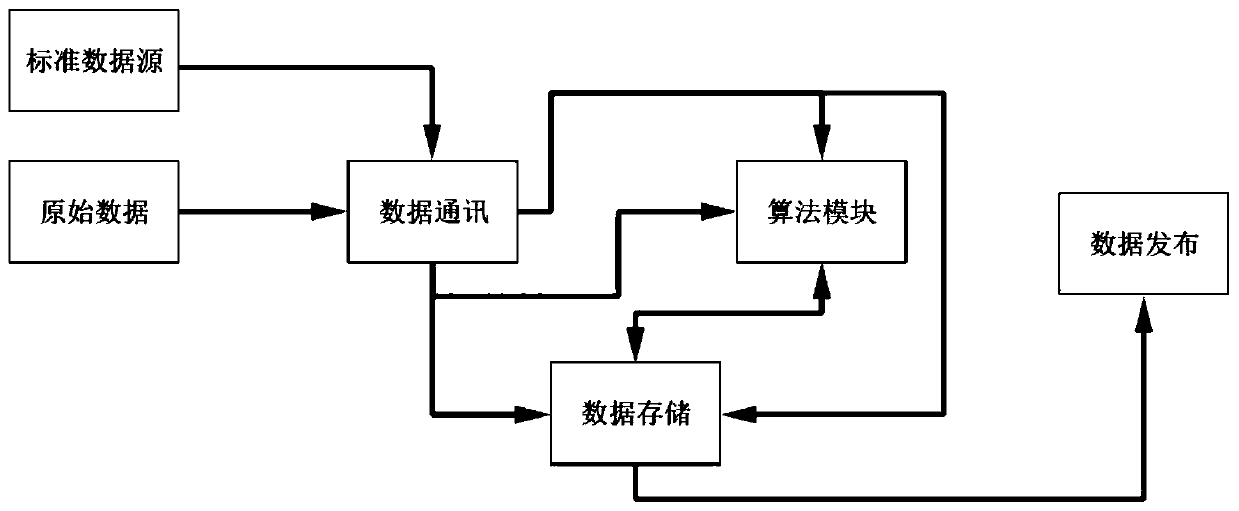

[0052] In this embodiment, the hardware equipment is composed of four parts: field equipment (that is, monitoring equipment, that is, electrochemical sensors), an Internet of Things server, a natio...

Embodiment 2

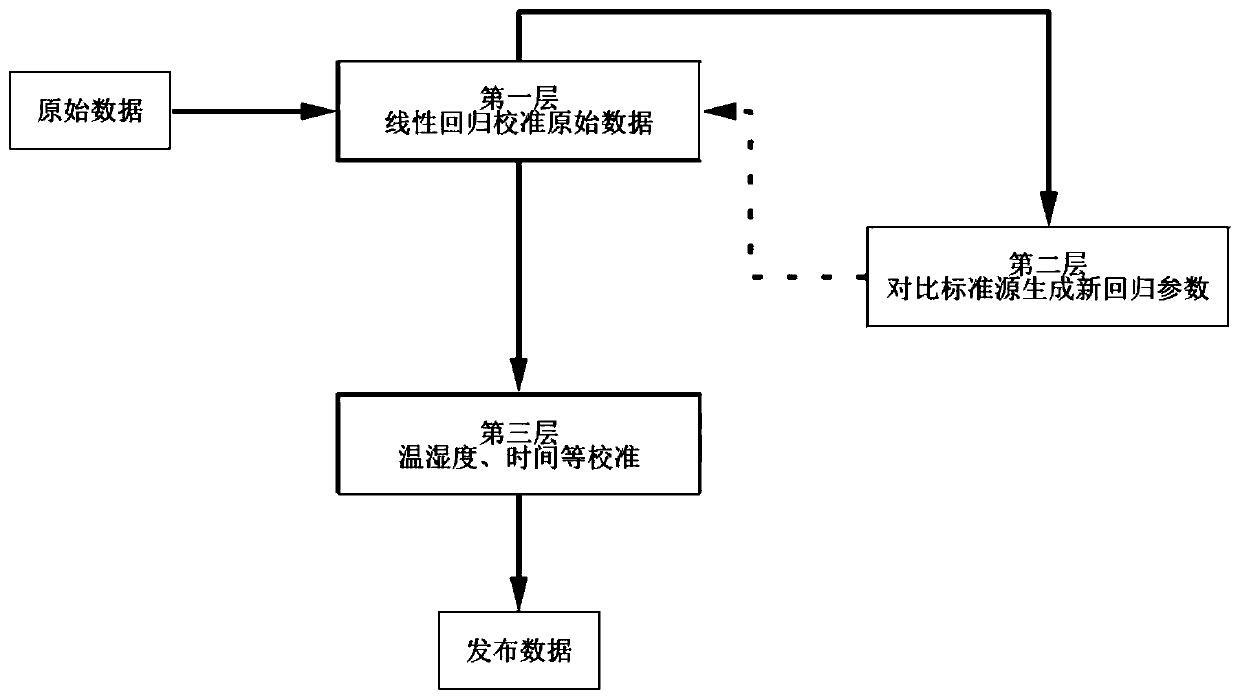

[0091] This embodiment discloses a gas monitoring calibration method based on linear regression, such as Figure 4 shown, including steps:

[0092] S11. Obtain the gas mixing monitoring value of the environment where the monitoring equipment is located;

[0093] S12. Convert the obtained mixed monitoring value into a gas component value based on linear regression;

[0094] S13. Comparing the converted gas composition value with the standard source data, and generating a new gas composition value according to the comparison result;

[0095] S14. Perform calibration processing on the obtained new composition value to obtain final composition information.

[0096] Further, the step S12 specifically includes:

[0097] S121. Construct a regression parameter pool based on the obtained mixed monitoring value based on the square of the linear regression and the minimum gradient direction;

[0098] S122. Perform a variance test and a level test on the parameters in the regression p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com