Production process and production equipment of motor rotor for unmanned aerial vehicle

A technology of production equipment and production process, which is applied in the production process of motor rotors for drones and its production equipment, can solve the problems of poor motor performance, low degree of automation, and low production efficiency, so as to prevent wear and eccentricity, improve Production efficiency and degree of automation, the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A production process of a motor rotor for drones includes the following steps:

[0048] S1: Turn the rotor shaft blank into shape, and heat it through an electric melting furnace; and paint the surface for use;

[0049] S2: Punching the rotor pieces into a rotor piece group for use;

[0050] S3: The rotor sheet group and the rotor shaft are punched and formed by the cooperation of a punching machine and a punching die;

[0051] S4: Test the straightness of the rotor shaft of the rotor and leave the factory without error.

[0052] In the specific embodiment of the present invention, in step S3, the rotor shaft is immersed in oil before the rotary shaft sheet group and the rotor shaft are stamped.

[0053] Compared with the prior art, the method disclosed in the present invention has the following beneficial effects: the production process is simple to operate, has lower technical requirements for staff, and is suitable for more work groups; the production efficiency is high, and th...

Embodiment 2

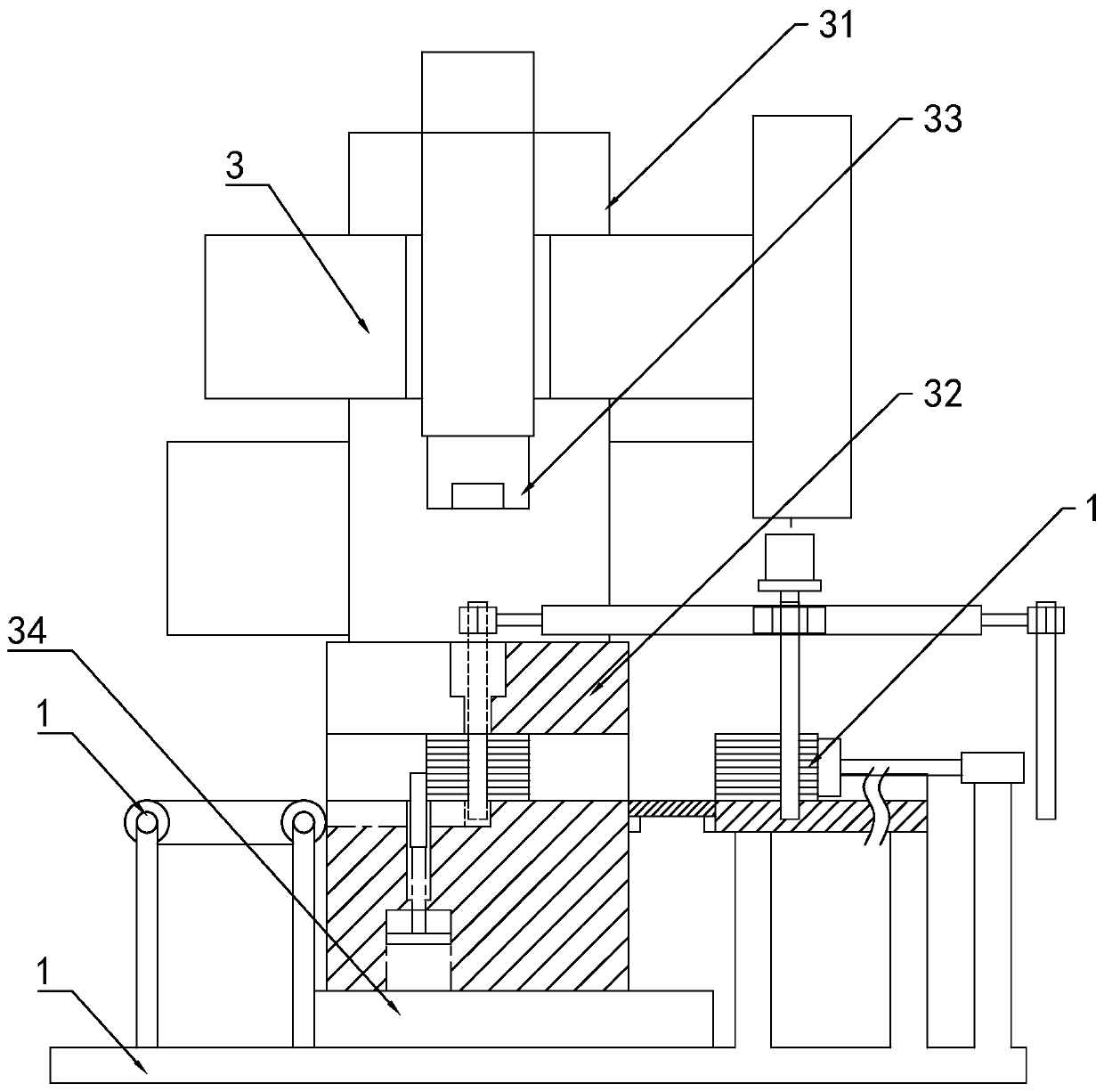

[0055] Such as Figure 1-4 As shown, in addition, the present invention also discloses a production equipment of a motor rotor for unmanned aerial vehicles, which in turn includes a turning device, a resistance furnace, a stamping device, and a straightness testing device according to the production process; the turning device is a CJK6130 CNC lathe ; The resistance furnace is a ZXRJ-2-75 well type resistance furnace.

[0056] In a specific embodiment of the present invention, the punching device includes a frame 1, a PLC control unit, a feeding unit 2, a punching unit 3, and a discharging unit 4;

[0057] The PLC control unit, the punching unit 3, the feeding unit 2 and the discharging unit 4 are all installed on the frame 1; the punching unit 3, the feeding unit 2, and the discharging unit 4 are all electrically connected to the PLC system; the discharging unit 4 is the conveyor belt.

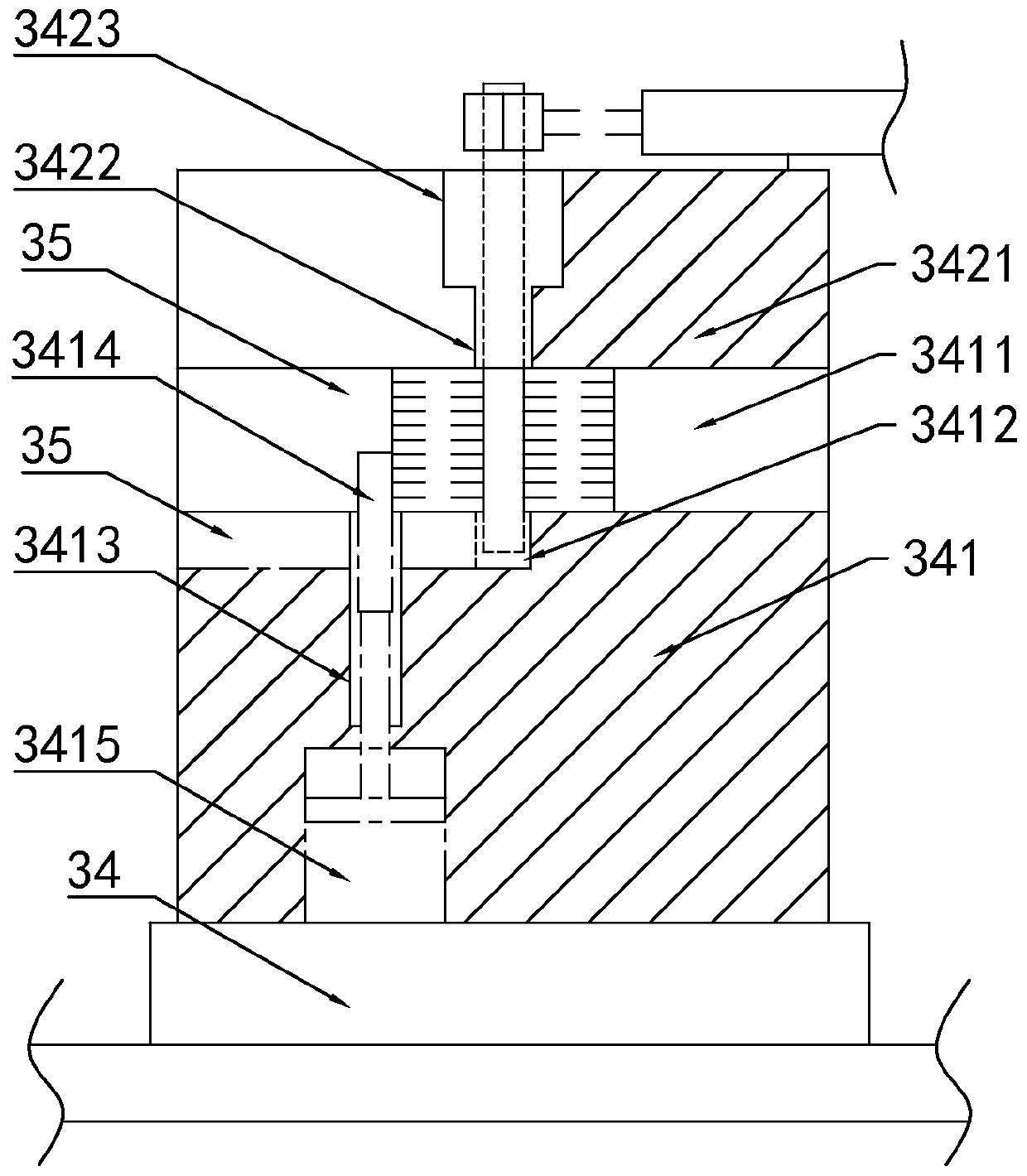

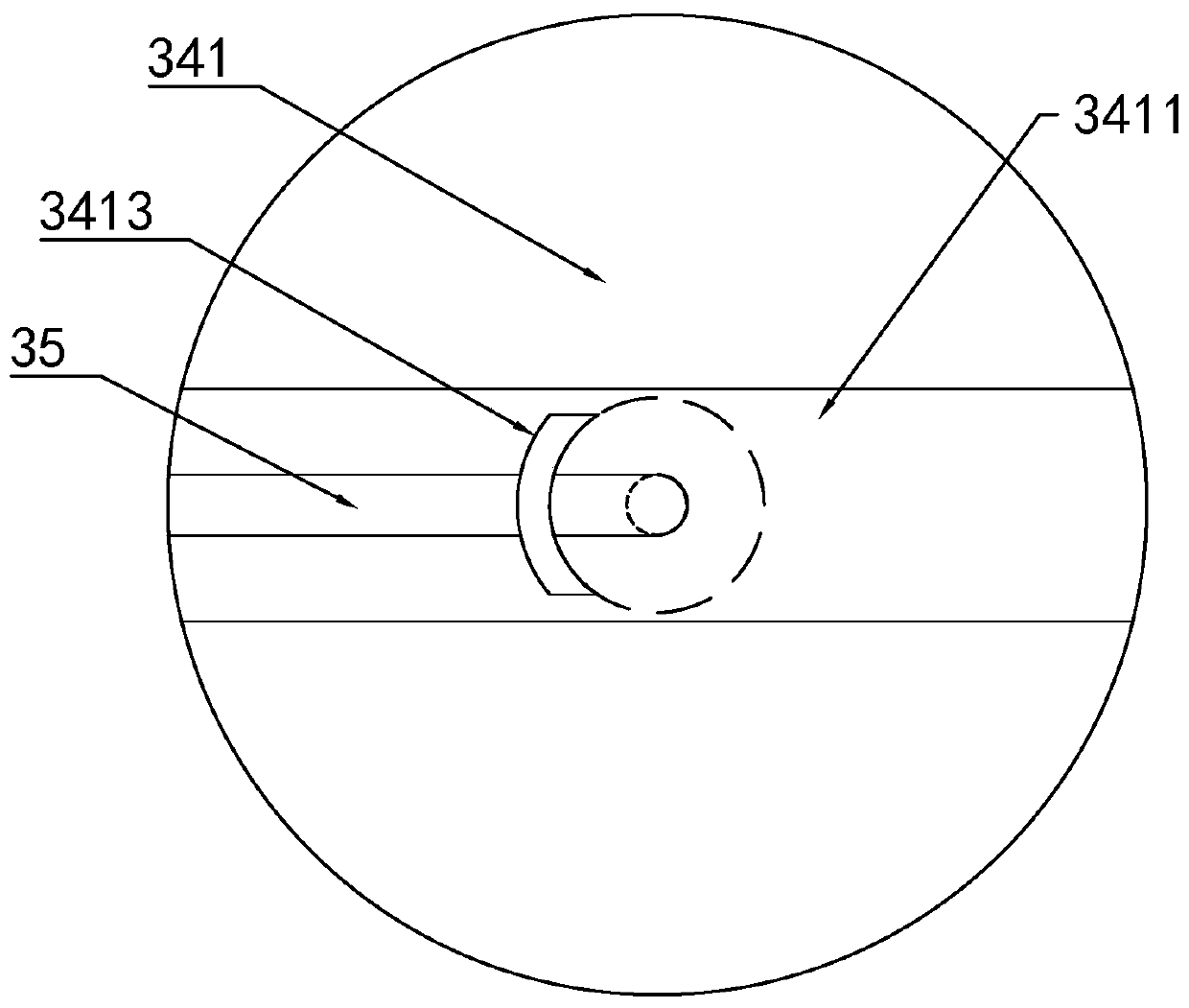

[0058] In the specific embodiment of the present invention, the punching unit 3 includes a punc...

Embodiment 3

[0064] Example 3, the difference from Example 2 is

[0065] Such as Figure 5-6 As shown, in the specific embodiment of the present invention, the feeding unit 2 includes a rotor sheet group feeding module 21 and a rotating shaft feeding module 22;

[0066] In a specific embodiment of the present invention, the rotor blade group feeding module 21 includes a feeding platform 211, a transverse drive cylinder 212, and a pushing plate 213 for pushing the rotor blade group; the feeding platform 211 is installed on the frame 1, two A feeding baffle 214 is installed on the side to form a feeding channel in the middle; the lateral drive cylinder 212 is installed on the frame, and the output end passes through the feeding channel toward the punching die 32; the push plate 213 is installed on the output of the lateral drive cylinder 212 And the pushing surface of the pushing plate 213 is set to a curved surface that fits the rotor sheet; the pushing plate 213 is installed with a displacement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com