Savoury filling composition and savoury food products

A technology of composition and flavoring agent, which is applied in the fields of baked food, dairy products, food science, etc., and can solve problems such as short shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

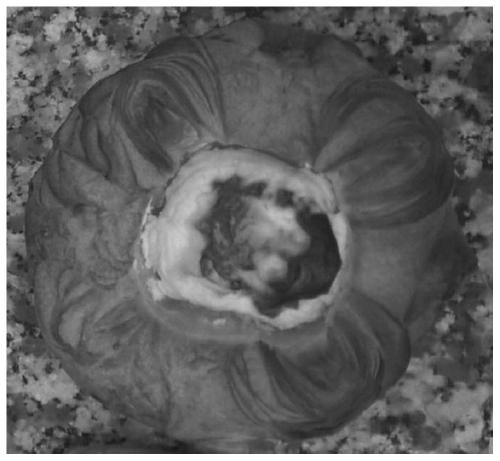

Image

Examples

Embodiment 1

[0139] Example 1: Cheese Flavoring - Different Acidulants

[0140] Cheese flavorings A-E were prepared using the different raw material components listed in Table 1. Compositions A-E differ in the amount of acidulant incorporated into the formulation.

[0141] Sample AA is a comparative example without adding any acidulant. In samples AB, the same amount of lactic acid as in starter product sample E was added.

[0142] Table 1: Cheese Flavoring Components

[0143]

[0144]

[0145] a : Contains 21% fat and 9.8% protein, dry matter 42%, pH 5.8

[0146] b : Contains starch and microcrystalline cellulose

[0147] c : Liquid rye starter products

[0148] Cheese flavoring preparation includes the following steps:

[0149] 1. In the first tank, dissolve the hydrocolloid in about 2 / 5 of the water under high shear.

[0150] 2. Add the starch and mix the mixture under high shear until completely dissolved.

[0151] 3. In a second tank, disperse the cheese powder and ch...

Embodiment 2

[0175] Example 2: Cheese Flavoring - Different Cheese Components

[0176] Cheese flavorings F-H were prepared using the ingredients listed in Table 4. Compositions F-H differ in the cheese components included in the recipe.

[0177] Table 4: Cheese Flavoring Components

[0178]

[0179]

[0180] a : Contains 21% fat and 9.8% protein, dry matter 42%, pH 5.8

[0181] b : Contains 15% fat and 11% protein, dry matter 27%, pH5.75

[0182] c : Contains starch and microcrystalline cellulose

[0183] d : Liquid rye starter product

[0184] The cheese conditioner was prepared and evaluated according to the method in Example 1. The physical properties of the cheese flavorings are shown in Table 5.

[0185] table 5

[0186] F G H Brix 28.5 30.3 26.8 pH 5.15 5.08 5.15 Water activity (AW) 0.93-0.96 0.93-0.96 0.93-0.96

[0187] Table 6 gives the overall ratings.

[0188] Table 6: Overall ratings of cheese flavorings

[0189] ...

Embodiment 3

[0191] Example 3: Cheese Flavor - Component Incorporation

[0192] Cheese flavorings I-K were prepared using the ingredients of composition F in Example 2. Compositions I-K differ in the timing of the addition of the components in the formulation.

[0193] I: according to the method for embodiment 1.

[0194] J: According to the method of Example 1, wherein step 3 is omitted, and cheese powder and cheese powder are directly added together with the components of step 4.

[0195] K: according to the method of embodiment 1, wherein step 9 is performed before step 8.

[0196] Cheese flavorings were evaluated according to the criteria in Example 1 (ie, scores were obtained by using the parameters and the scale of points, with scores 1, 2 and 3 and the total score). The physical properties of the cheese flavorings are shown in Table 7.

[0197] Table 7

[0198] I J K Brix 28.5 30.3 26.8 pH 5.15 5.08 5.15 Water activity (AW) 0.93-0.96 0.93-0.9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com