Virtual instrument-based balance coefficient tester and test method

A technology of balance coefficient and virtual instrument, which is applied in the direction of elevators, transportation and packaging, etc., can solve the problems of large errors and low precision, and achieve the effect of solving large errors, improving precision and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

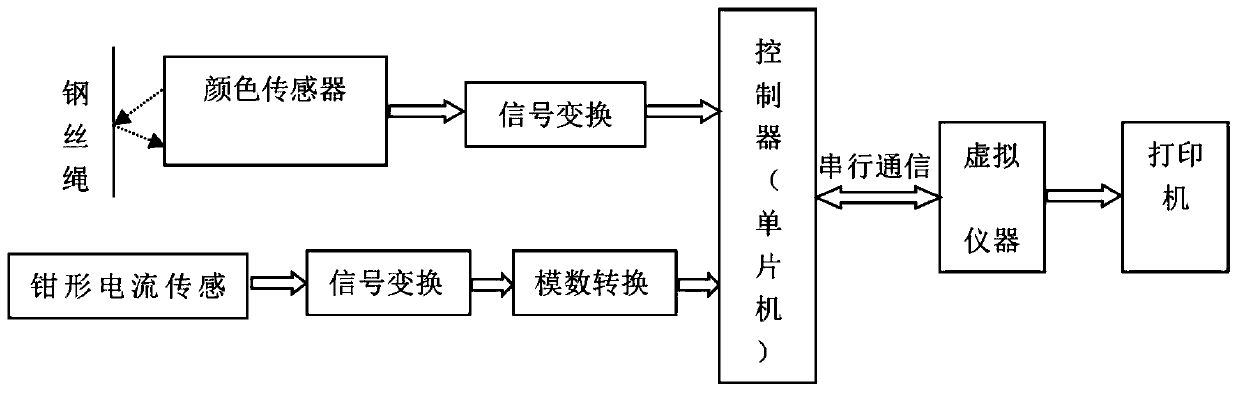

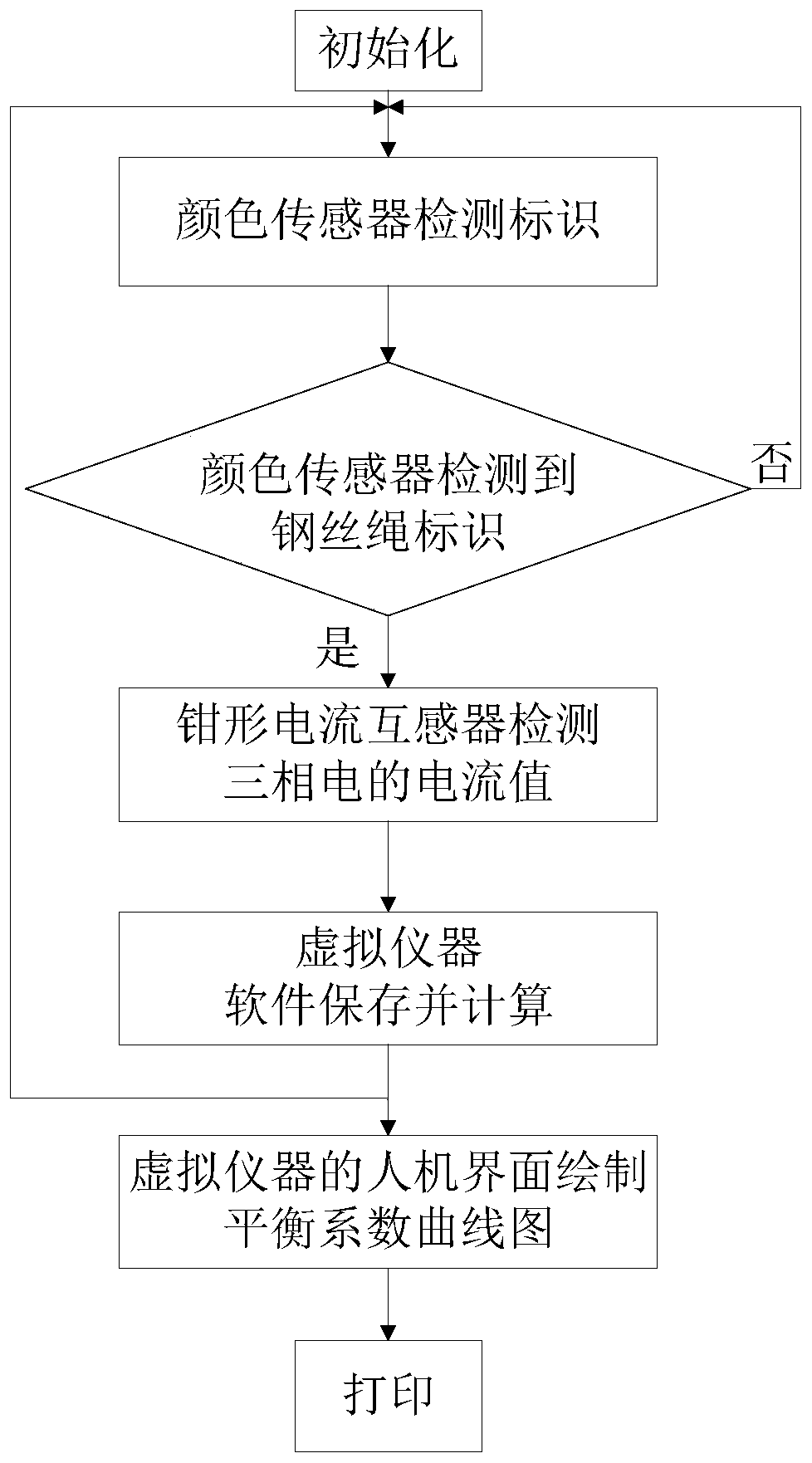

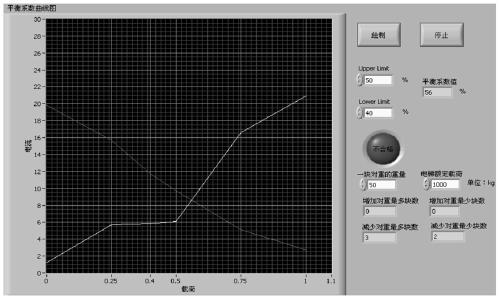

[0046] see figure 1 , figure 2 as well as image 3 , this embodiment provides a virtual instrument-based balance coefficient tester, which is used to test the balance coefficient of a traction-driven elevator. The tester of this embodiment uses the photoelectric signal to trigger and record the current value instead of visually recording a certain phase current output by the elevator inverter when the elevator car and the counterweight are on the same horizontal line, which avoids the human error caused by visual inspection, and improves the test performance. purpose of precision. Wherein, the tester includes a color sensor, a clamp current sensor, a controller, a computer (which is provided with a virtual instrument) and a printer.

[0047] The color sensor is installed on the base of the traction machine of the elevator, and is used to align the white mark marked on the elevator traction wire rope when the elevator car and the counterweight are at the same level. The whi...

Embodiment 2

[0061] This embodiment provides a virtual instrument-based balance coefficient tester, which adds a test vehicle on the basis of Embodiment 1. Among them, the test vehicle includes a car body, a platform, a power mechanism, multiple wheels and load cells. The car body has a storage space for a plurality of weights, the storage space can generally be set large enough, and can be an open space. A platform is provided at the bottom of the containment space and is used to support all weights. The platform can move relative to the vehicle body without contact between the two. A plurality of wheels are rotatably installed on the bottom of the car body, and drive the car body to run through the rotation. The wheels can adopt wear-resistant and pressure-resistant wheels, which can bear enough pressure. The power mechanism is installed in the vehicle body and is used to drive at least one pair of coaxially arranged wheels to rotate. The power mechanism generally adopts a servo moto...

Embodiment 3

[0065] see Figure 4 , this embodiment provides a virtual instrument-based balance coefficient tester, which adds an automatic counterweight system on the basis of Embodiment 2. The automatic counterweight system belongs to the partial structure of the test vehicle, and includes at least two splints 2 , a driving assembly 3 , a lifting rod 4 , a rotating motor 5 and a rotating rod 6 .

[0066] Lifting rod 4 is divided into two parts, and a part is fixed section, and another part is lifting section. The fixed section of elevating rod 4 is fixed on the car body 1, and rotating motor 5 is installed on the elevating section of elevating rod 4. In this embodiment, the lifting rod 4 can adopt an existing telescopic member such as a hydraulic rod, which has a relatively large lifting force and can lift at least one weight 7 . The rotating rod 6 is perpendicular to the axial direction of the lifting rod 4 , and the rotating motor 5 is used to drive the rotating rod 6 to rotate in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com