Metal plate plating device facilitating recovery of cathode rare metals

A technology for metal sheets and rare metals, applied in the field of metal sheet coating devices, can solve the problems that rare metals cannot be recovered quickly, and achieve the effects of improving plating quality, avoiding water splashes, and reducing fluctuation frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

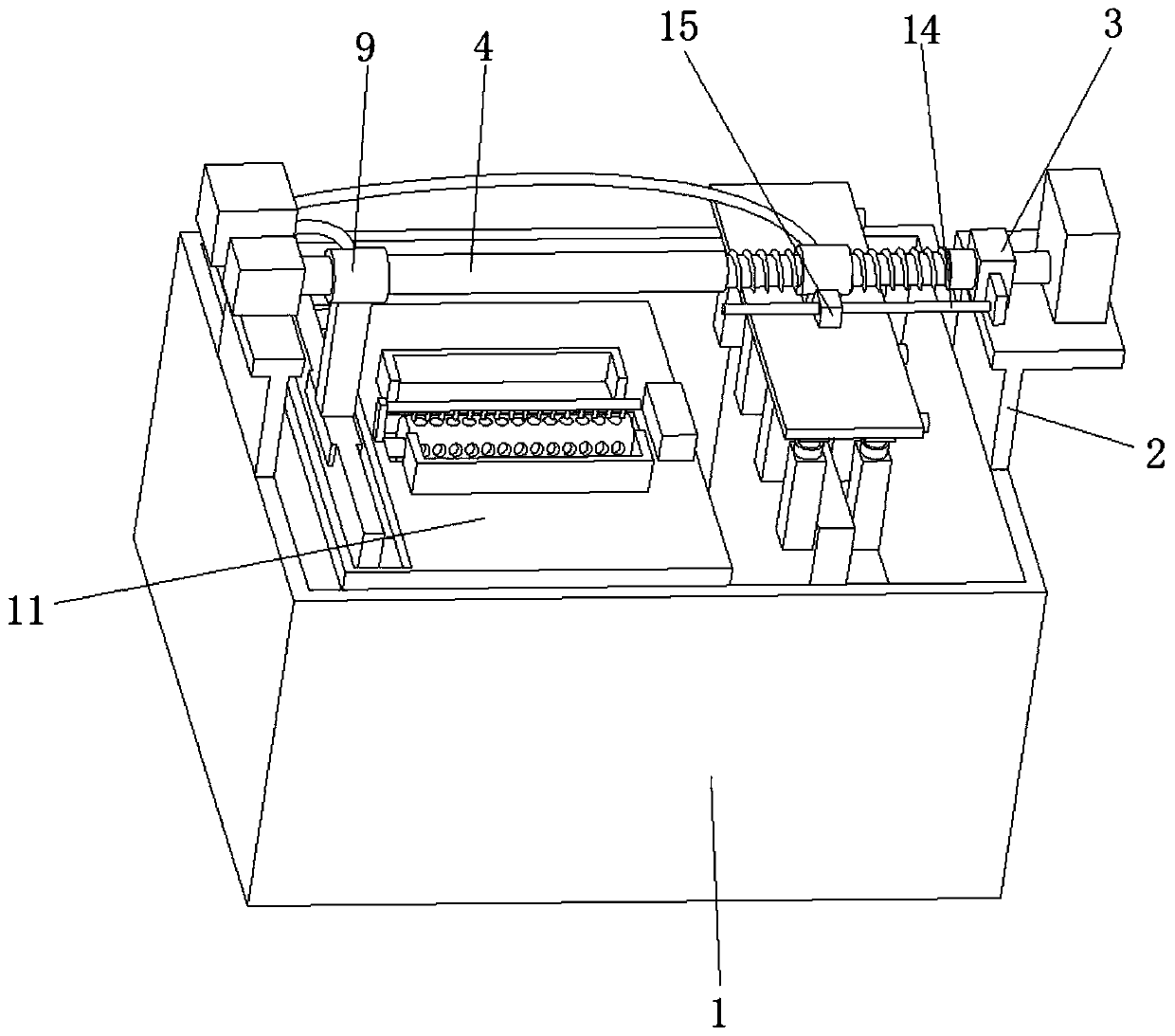

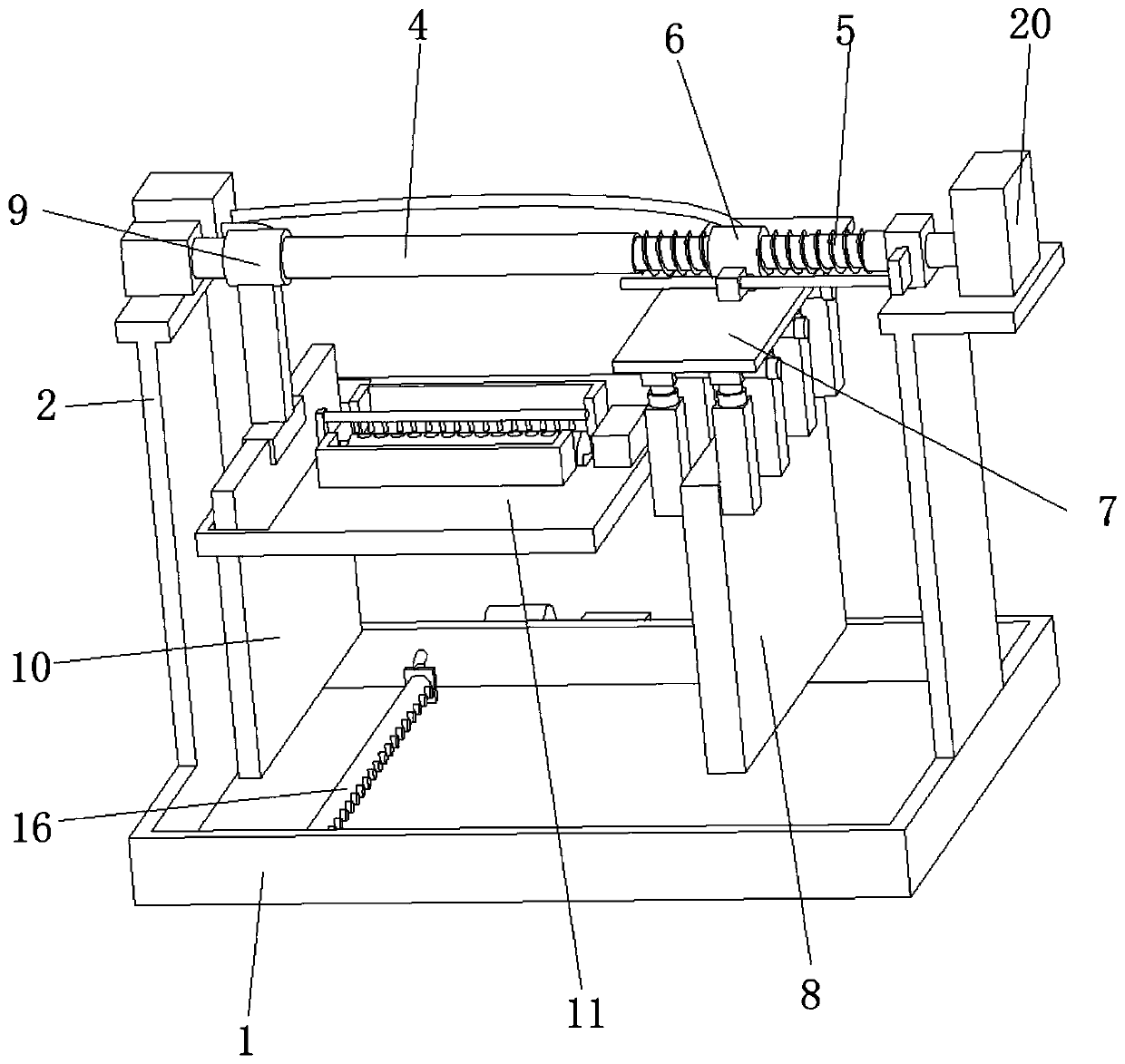

[0036] Such as Figure 1-3 As shown, the present invention provides a technical solution: a metal plate coating device that facilitates the recovery of cathode rare metals, including a coating tank 1, and both sides of the outer top of the coating tank 1 are fixedly connected with supporting top frames 2, supporting The top of the top frame 2 is fixedly connected with a support bearing 3, the inside of the support bearing 3 runs through and is connected with an insulating rotary rod 4, the outer surface of the insulating rotary rod 4 is fixedly connected with a reciprocating threaded rod 5 near the right side, and the reciprocating thread The outer surface of the rod 5 is sheathed and threadedly connected with a cathode threaded block 6, and the bottom end of the cathode threaded block 6 is fixedly connected with a cathode clamping mechanism 7, and the bottom of the cathode clamping mechanism 7 is provided with a metal plate 8 to be plated, an insulating screw The left side of...

Embodiment 2

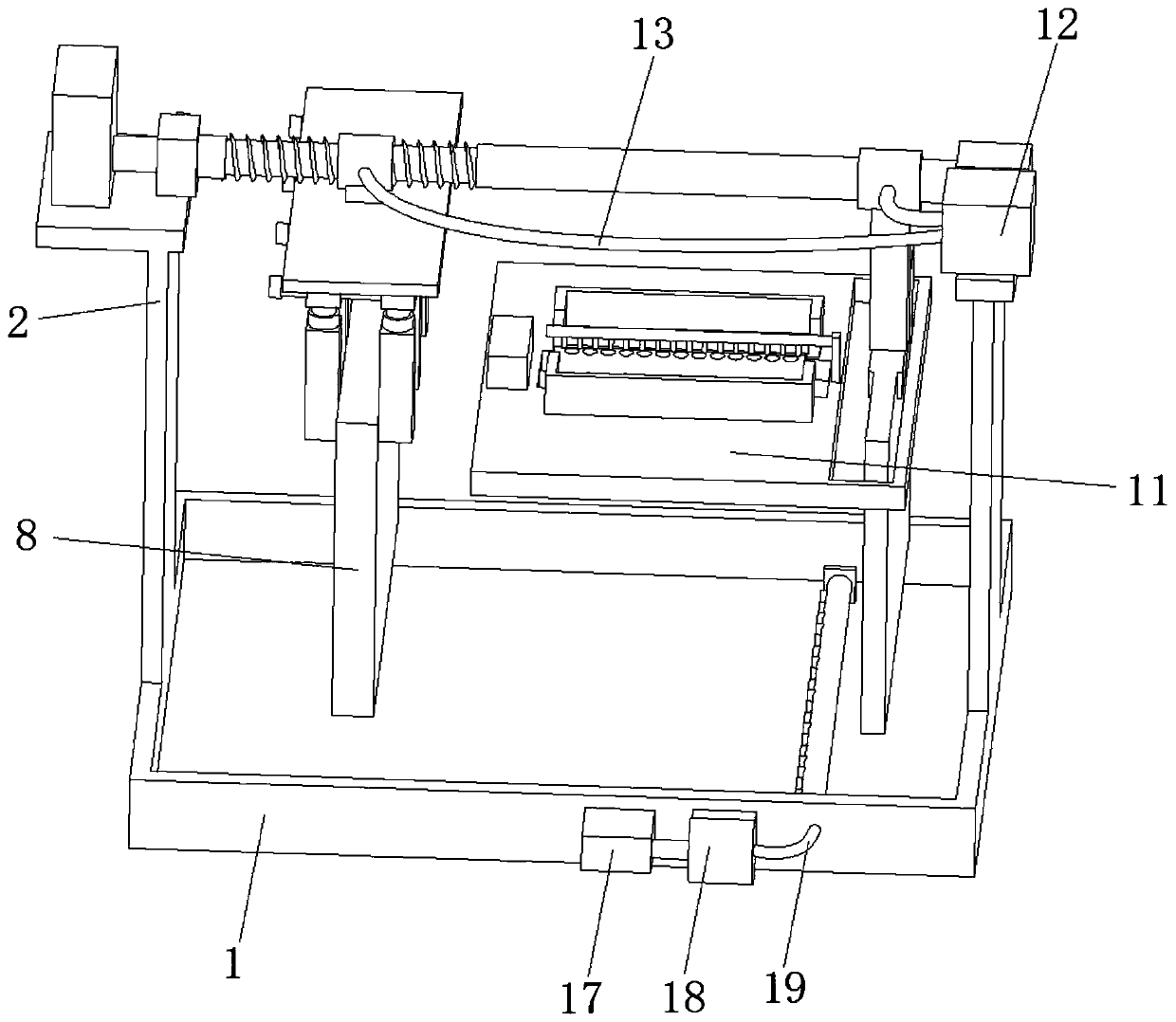

[0042] Such as Figure 4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a metal plate coating device that facilitates the recovery of cathode rare metals. The cathode clamping mechanism 7 includes a cathode top plate 71, and the top of the cathode top plate 71 is connected to the cathode The threaded sleeve block 6 is fixedly connected, and the left side of the bottom of the cathode top plate 71 is uniformly fixedly connected with a support block 72, and the right side of the support block 72 is connected with a fastening bolt 73 in rotation, and the right side outside the fastening bolt 73 is sleeved and threaded. There is an adjusting sleeve block 74 , and the bottom of the adjusting sleeve block 74 and the support block 72 are both provided with a cathode wire clamping block 75 .

[0043] The top inside the cathode wire clamp block 75 is fixedly connected with an installation sleeve groove 76, and the bottom end of the adjustmen...

Embodiment 3

[0046] Such as Figure 5 with 6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a metal sheet plating device that facilitates the recovery of cathode rare metals, the plating solution cleaning mechanism 11 includes a floating plate 111, and the floating plate The left side inside 111 is provided with a movable groove 112, and the inside of the movable groove 112 is sleeved on the outside of the anode plate 10, and the bottom surface of the floating plate 111 is uniformly provided with attachment holes 113, and the middle position of the floating plate 111 is rotatably connected with a cleaning roller 114 , the surface of the cleaning roller 114 is provided with holes, and the bottom of the cleaning roller 114 extends to the bottom of the floating plate 111 . The floating plate 111 covers the left side of the inside of the plating tank 1. When the fluidity of the electrolyte increases, the plating solution cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com