Lead frame for a battery apparatus of an electric vehicle

A lead frame and frame technology, applied in the direction of battery/battery traction, battery/fuel cell control devices, batteries, etc., can solve the problems of high structural consumption, achieve the effect of simplifying consumption, simplifying complexity, and improving prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

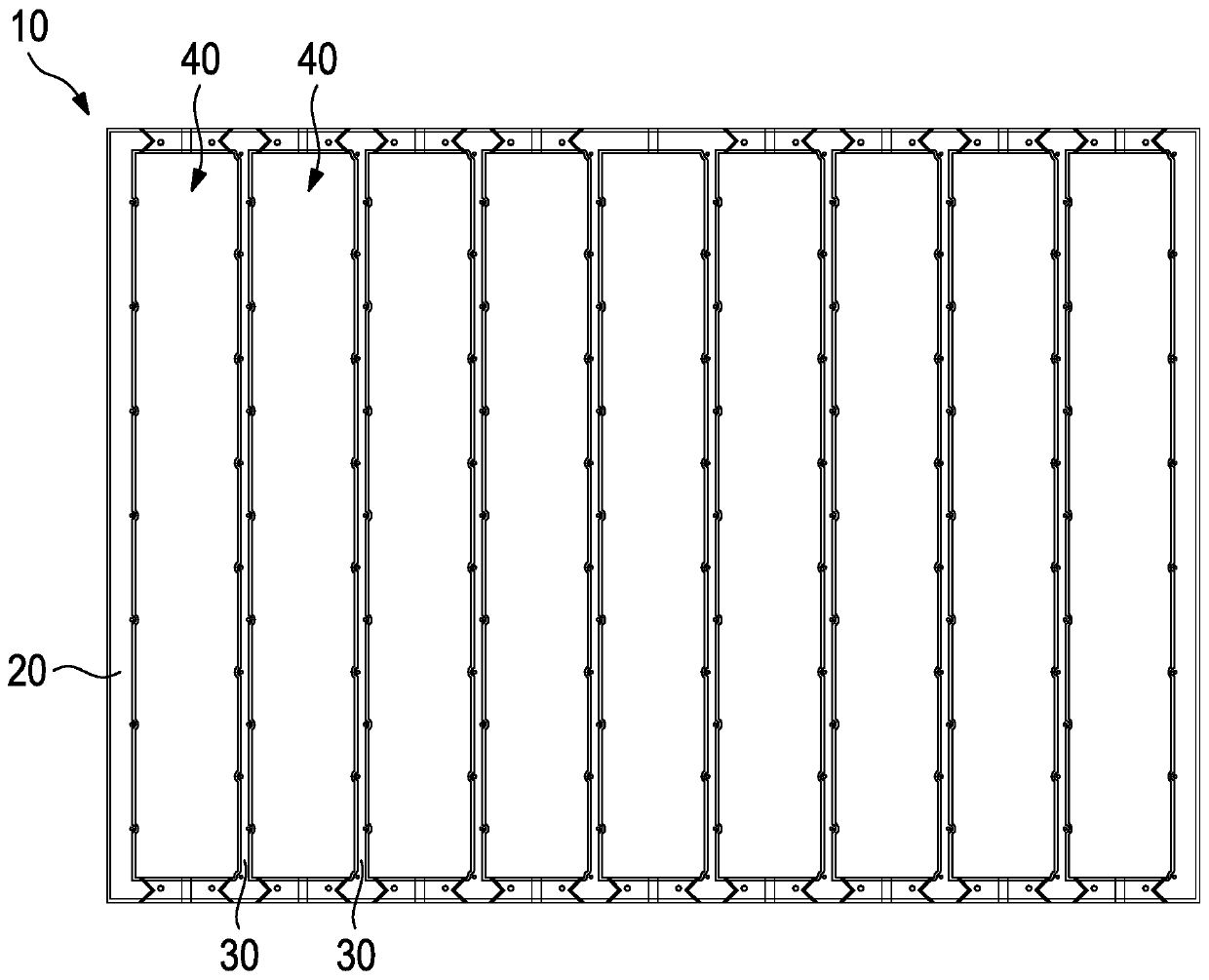

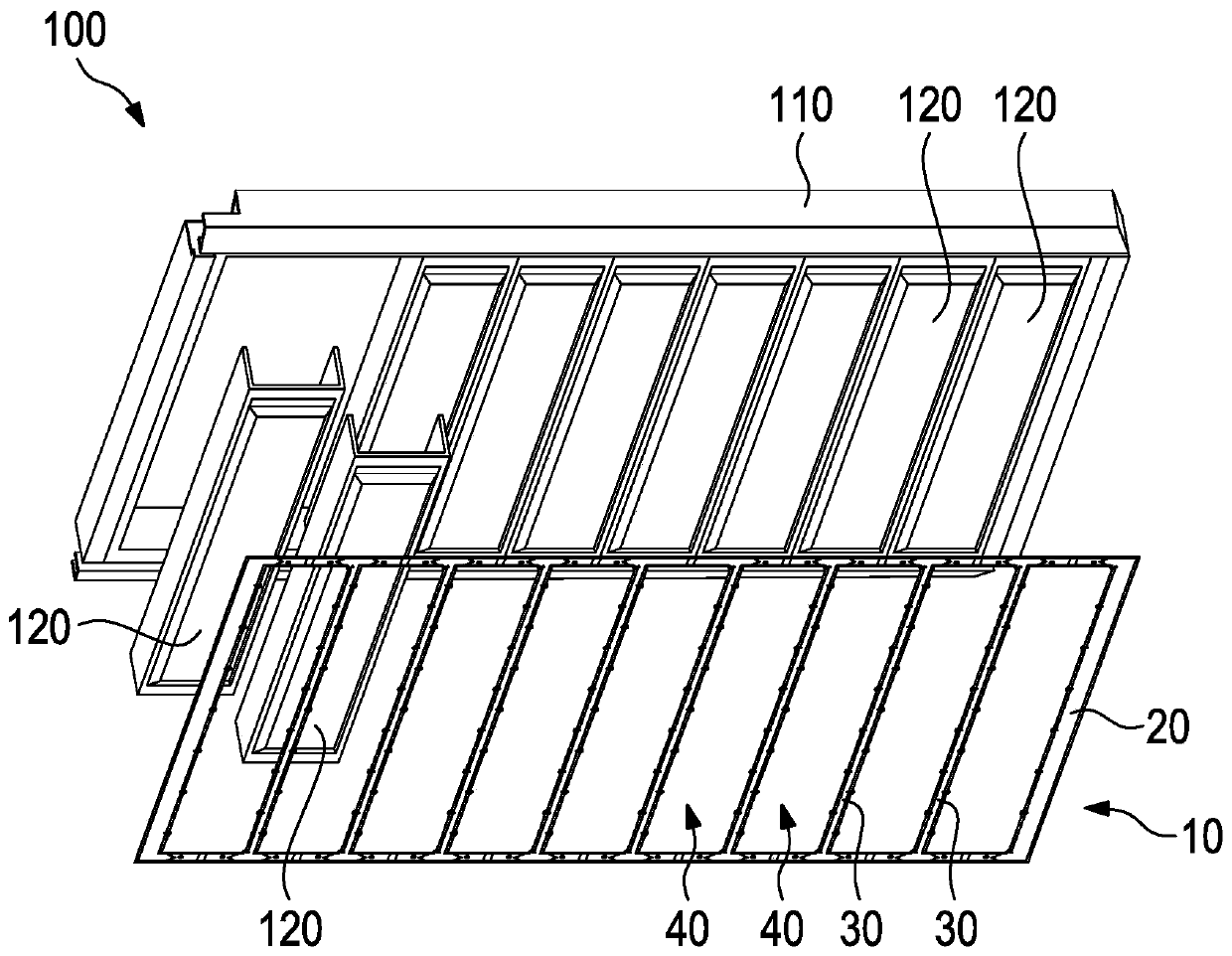

[0035] figure 1 and figure 2 A lead frame 10 according to the invention is shown schematically. The lead frame is produced in one piece from the base material and has a surrounding frame section 20 . The frame section 20 is divided into corresponding nine module receptacles 40 by a number of eight individual dividing sections 30 .

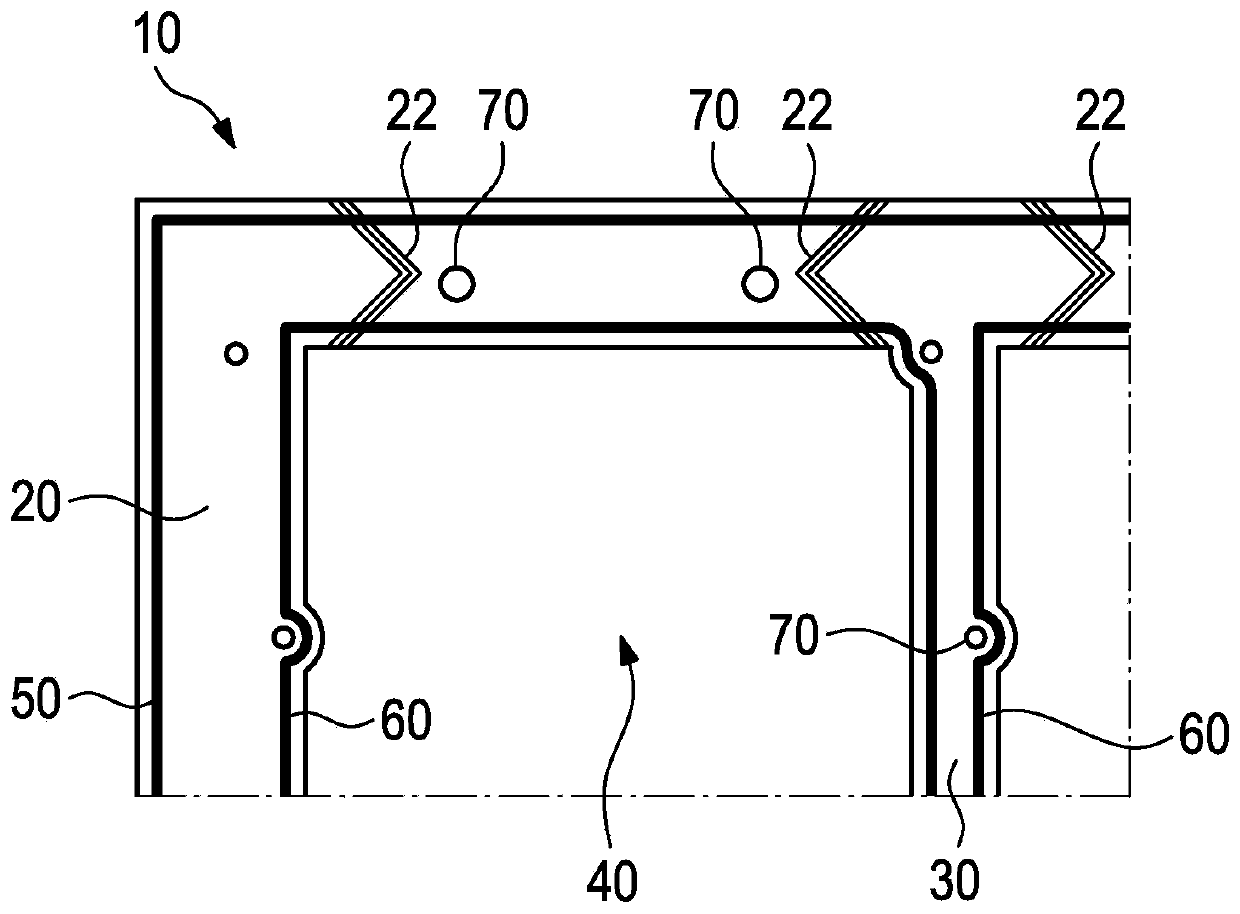

[0036] as in figure 2 As can be seen in , two sealed boundaries can be seen. Here, on the one hand, it is an inner sealing means 60 which surrounds each of these module receptacles 40 . To this end, the inner sealing means 60 extend partly through the frame section 20 and partly through the corresponding partition section 30 . Furthermore, external sealing means 50 are provided, which are arranged only in the frame section 20 . Thus, the outer sealing means 50 encloses the entire frame section and acts as a second outer barrier preventing the passage of fluid from the outside inwards into the installation space of the electrical component. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com