An organic vegetable growing device

A planting device and technology for organic vegetables, which are applied in planting methods, parts of planters, planters for spreading, etc., can solve the problems of inability to guarantee the same spacing between vegetables and unfavorable growth of vegetables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

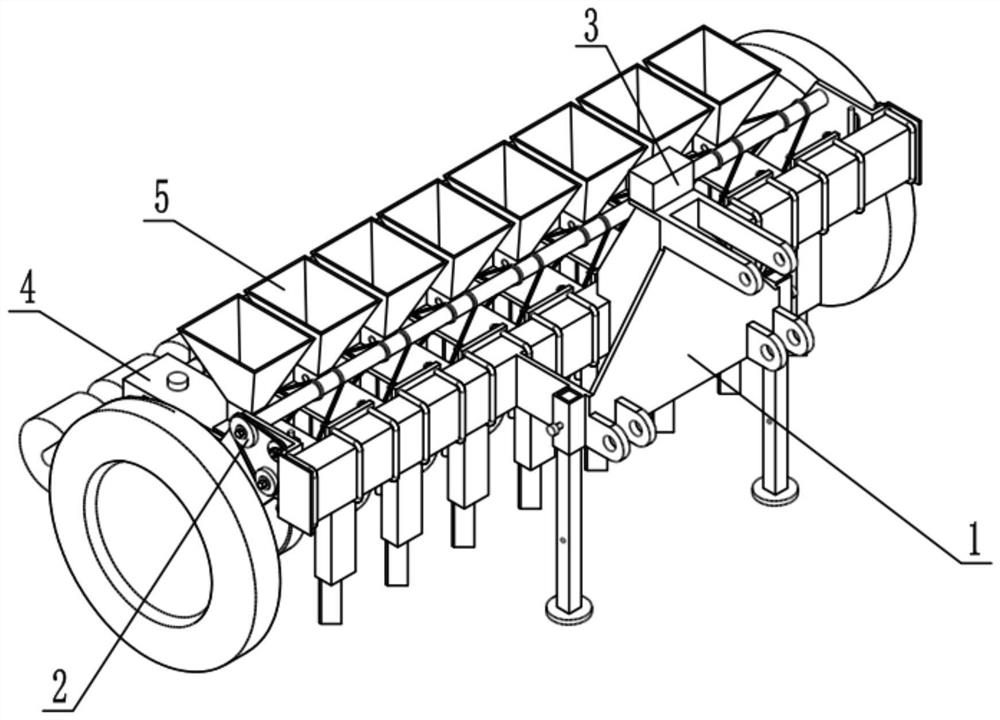

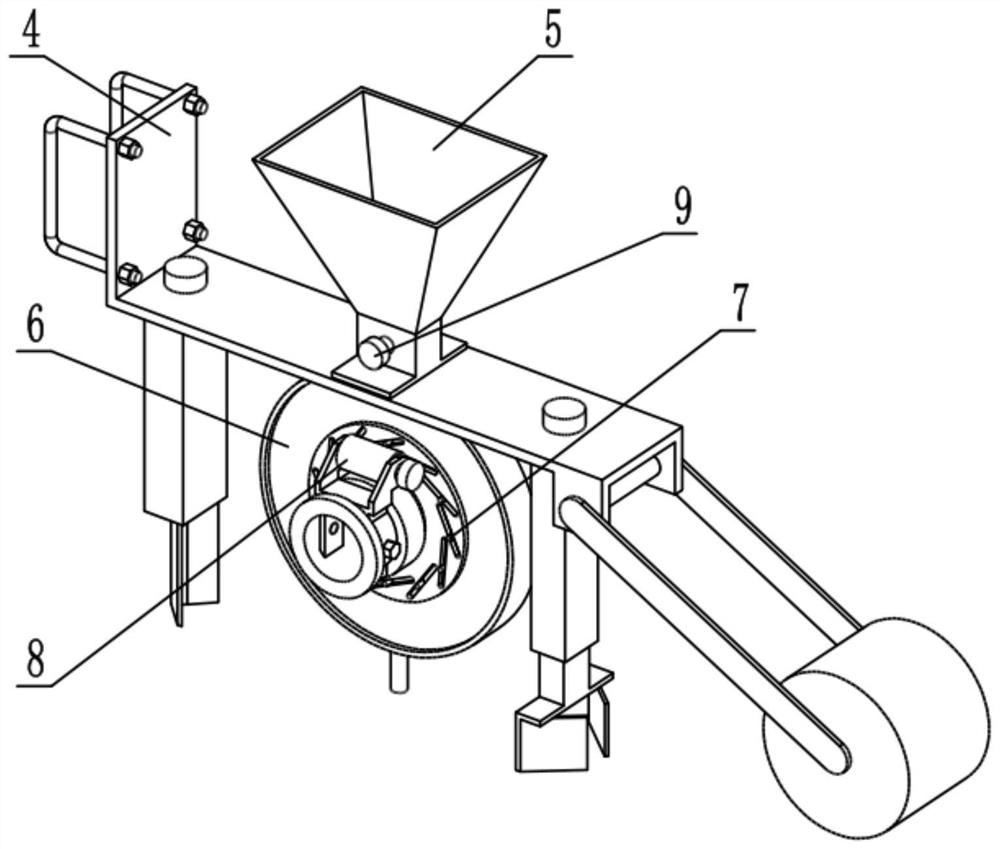

[0031] like Figure 1-13 As shown, an organic vegetable planting device includes a main frame mechanism 1, a transmission mechanism 2, an air pump 3, a sub-rack mechanism 4, a seed box mechanism 5, a seeding mechanism 6, a seed seed carrier mechanism 7, a seed seed adjustment mechanism 8, The stirring mechanism 9 and the axis mechanism 10, the transmission mechanism 2 is connected to the main frame mechanism 1, the air pump 3 is fixedly connected to the main frame mechanism 1, and the sub-rack mechanism 4 is provided with a plurality of Each of the sub-rack mechanisms 4 is fixedly connected to the main frame mechanism 1 , a seed box mechanism 5 is fixedly connected to the plurality of sub-rack mechanisms 4 , and a seeding mechanism 6 is rotatably connected to the plurality of seed box mechanisms 5 . A plurality of seed grain supporting mechanisms 7 are slidably connected inside 6, and a plurality of seed grain adjusting mechanisms 8 are rotatably connected to the plurality of se...

specific Embodiment approach 2

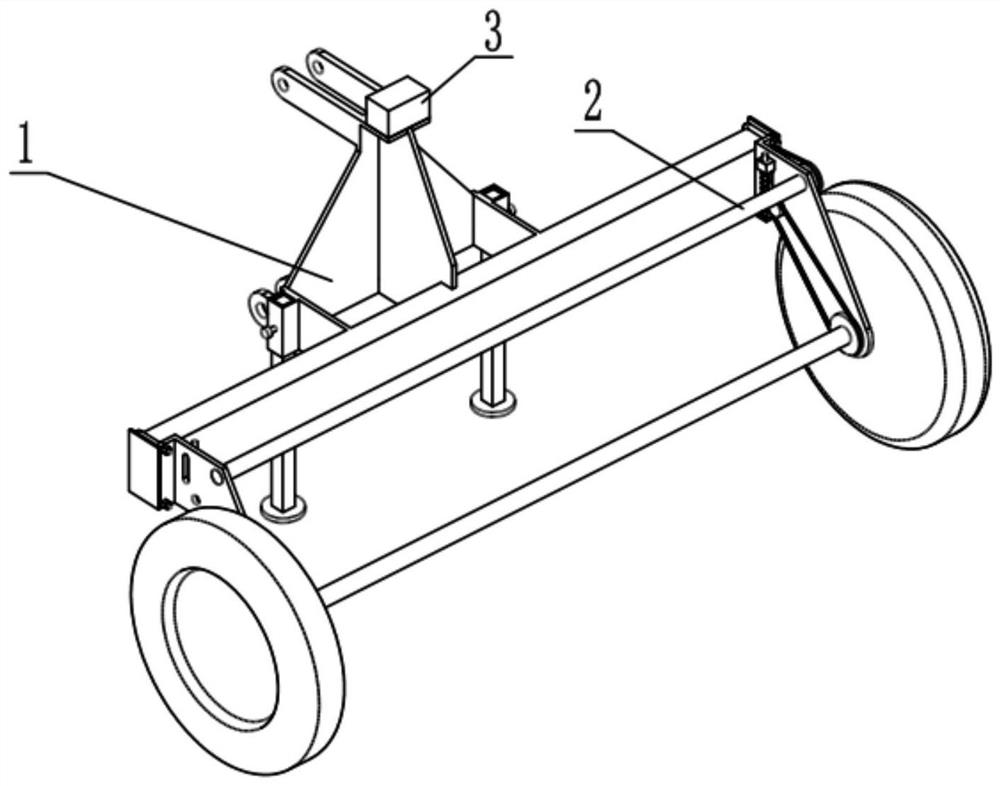

[0033] like Figure 1-13 As shown, the main frame mechanism 1 includes a main beam 1-1, a side plate 1-2, a moving wheel 1-3, outriggers 1-4, a traction frame 1-5, a tensioning carriage 1-6, a limiter Position bolts 1-7 and moving axles 1-8, the traction frame 1-5 is fixedly connected to the middle of the main beam 1-1, both ends of the main beam 1-1 are fixedly connected with side plates 1-2, and the moving axles 1- 8. Rotationally connected to the two side plates 1-2, both ends of the moving wheel shaft 1-8 are fixedly connected with moving wheels 1-3, and the tensioning carriage 1-6 is fixedly connected to the side plate 1-2 at the right end , there are two outriggers 1-4, the two outriggers 1-4 are slidably connected to both ends of the traction frame 1-5, there are two limit bolts 1-7, and two limit bolts 1-7 It is slidably connected with the two outriggers 1-4 respectively and is fixedly connected with the traction frame 1-5 through threads, and the air pump 3 is fixedl...

specific Embodiment approach 3

[0035] like Figure 1-13 As shown, the transmission mechanism 2 includes a transmission shaft 2-1, a transmission sprocket I2-2, a fixing bolt I2-3, a transmission sprocket II2-4, a fixing bolt II2-5, a transmission wheel shaft 2-6, a spring 2 -7. The tensioner 2-8 and the tensioner seat 2-9, the transmission shaft 2-1 is rotatably connected to the two side plates 1-2, and the transmission sprocket I2-2 is fixedly connected to the two side plates 1-2 through the fixing bolts I2-3 The right end of the transmission shaft 2-1, the transmission wheel shaft 2-6 is rotatably connected to the side plate 1-2 at the right end, the transmission sprocket II 2-4 is fixedly connected to the right end of the transmission wheel shaft 2-6 through the fixing bolt II 2-5, and the spring 2-7 is sleeved on the tensioning carriage 1-6, the tensioning wheel 2-8 is rotatably connected to the tensioning wheel base 2-9, and the tensioning wheel base 2-9 is slidably connected to the tensioning carriage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com