Non-woven carpet production line

A production line and carpet technology, applied in textiles and papermaking, spray/jet textile material treatment, coating, etc., can solve problems affecting the use of fabrics, achieve fast cooling, increase the contact area, and facilitate use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

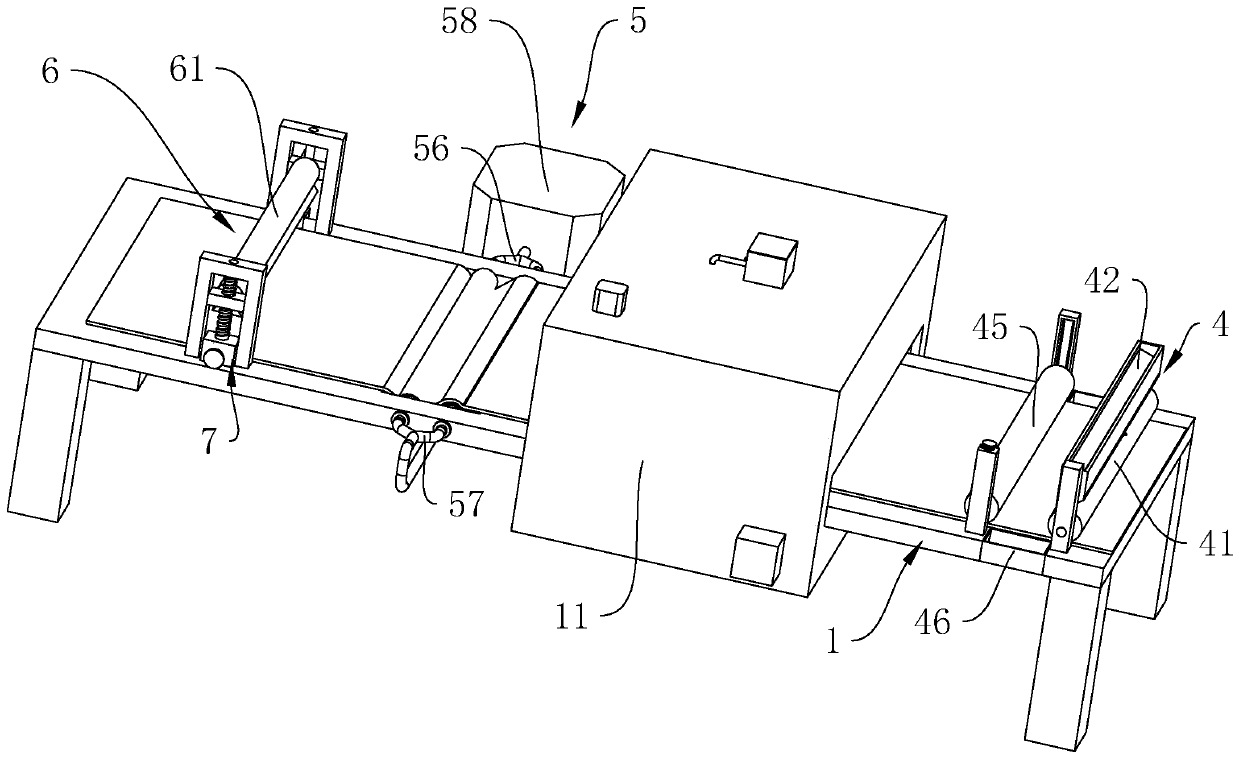

[0046] refer to figure 1 , figure 2 , is a non-woven carpet production line disclosed by the present invention, including a workbench 1 for installing production equipment, a drying box 11 for drying cloth is arranged on the workbench 1, and a pair of Drying unit for fabric drying. The drying component is a hot air pipe, and the hot air is sent to the hot air pipe by the hot air blower to dry the cloth. One side of the drying component is provided with a leveling component 2 .

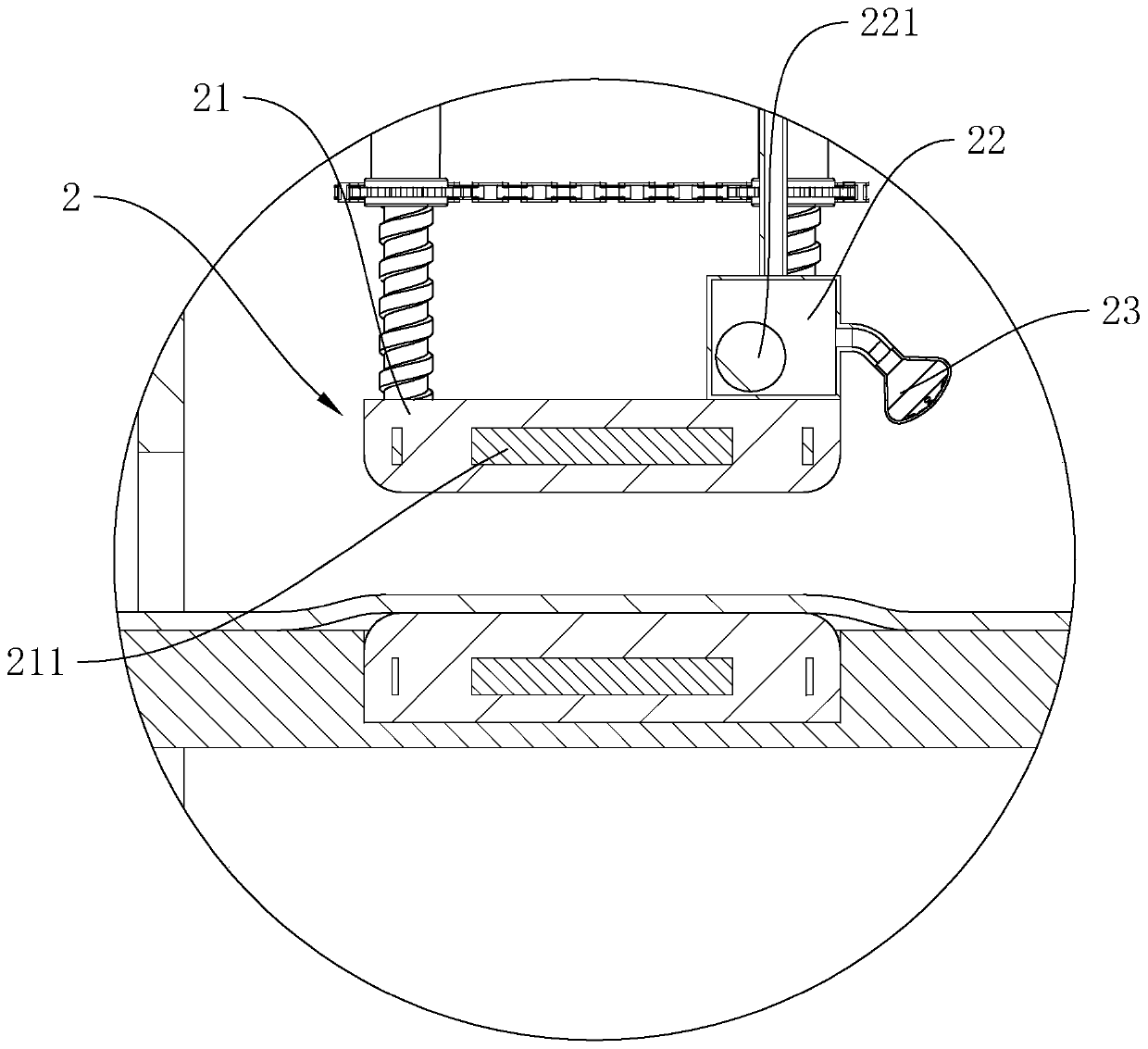

[0047] The leveling assembly 2 includes a pair of screeds 21 corresponding up and down. The shape of the two screeds 21 is preferably a square block with an arc-shaped side wall, and the material thereof is preferably metal. The screed 21 is also provided with an electric heating block 211 for heating the screed 21. The shape of the electric heating block 211 is preferably square...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com