A preformed aluminum alloy extrusion molding device and molding process

An extrusion molding and aluminum alloy technology, which is applied in the field of preformed aluminum alloy extrusion molding devices and molding technology, can solve the problems of reducing processing efficiency, increasing aluminum alloy processes, and lack of anti-sticking mechanism, etc., to improve processing efficiency , Reduce the processing steps, shorten the processing interval effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

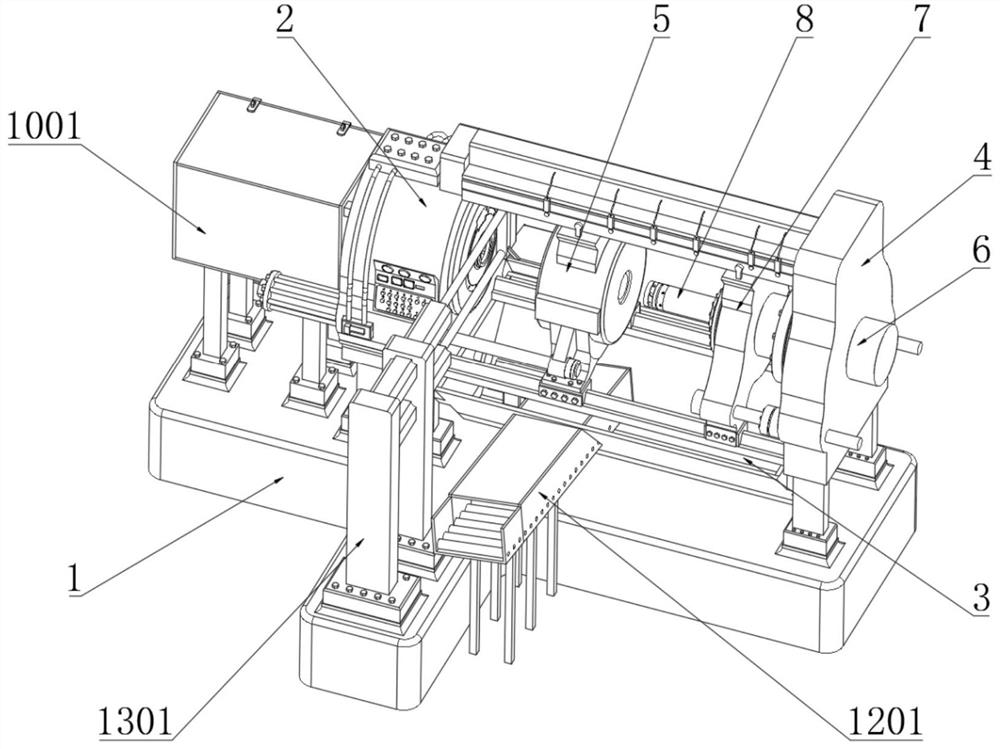

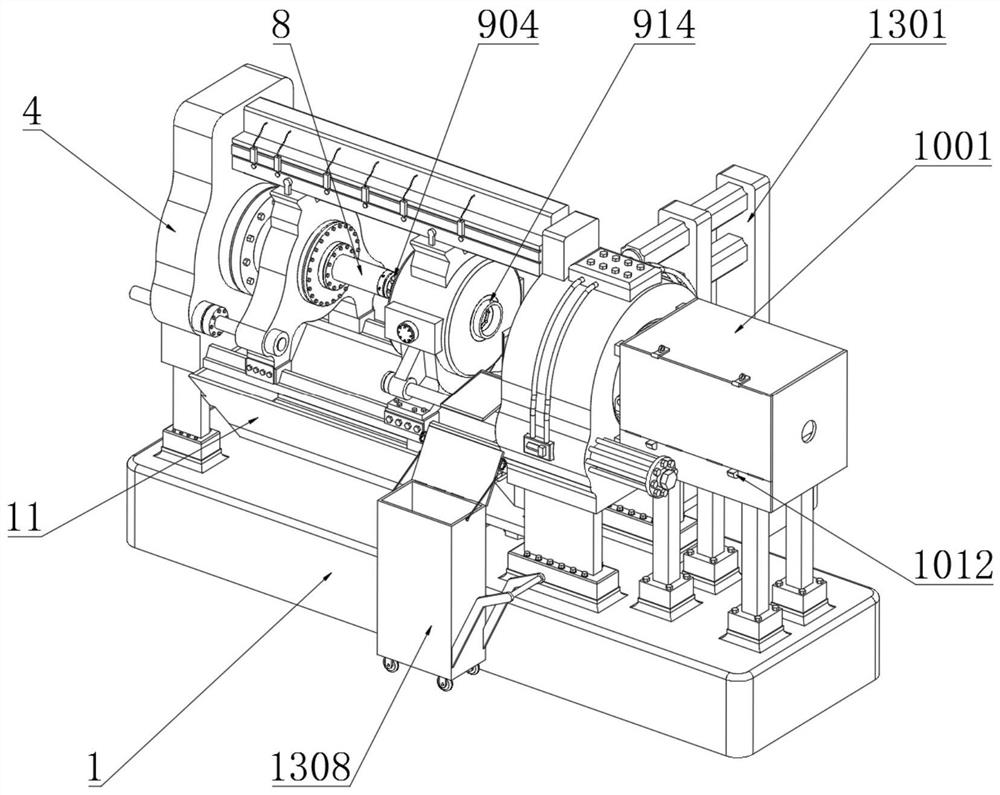

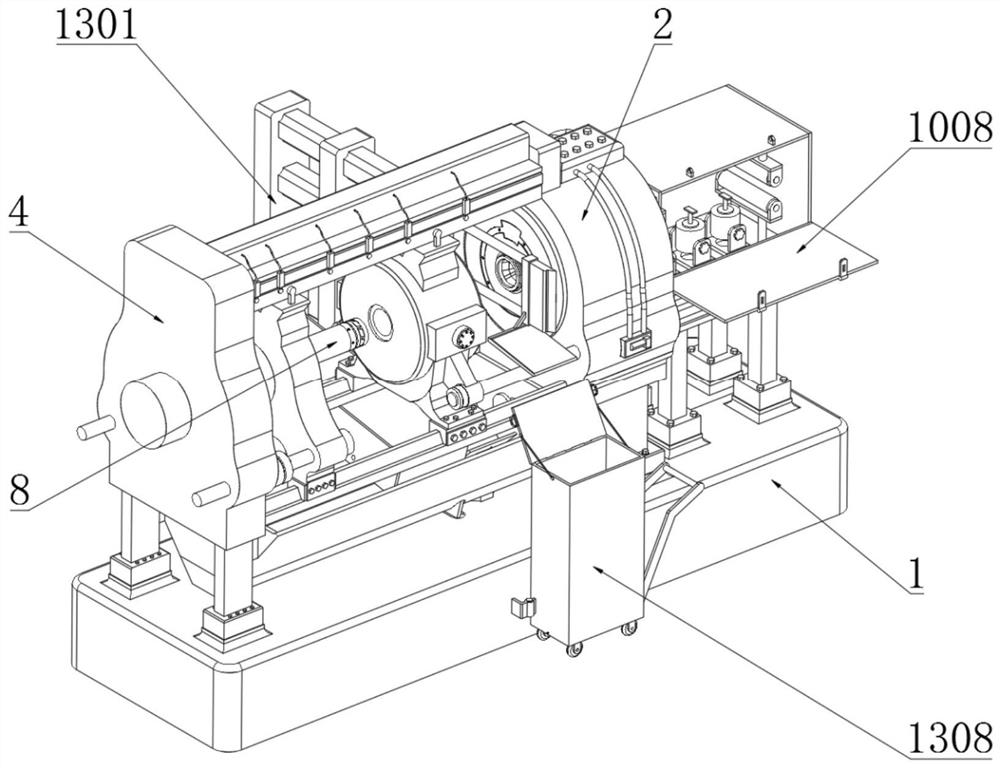

[0062] Example: such as Figure 1-8 As shown, the present invention provides a technical solution, a preformed aluminum alloy extrusion molding device, including a mounting base 1, the top end of the mounting base 1 is fixedly connected with an extruder body 2, and the bottom of one side of the extruder body 2 Both ends are fixedly connected with the installation slide rail 3, the top of the installation base 1 is fixedly connected with the drive installation seat 4 at one end of the installation slide rail 3, and the top of the installation slide rail 3 is provided with an auxiliary extruder at the position corresponding to the side of the extruder main body 2. The pressure seat 5 and the middle part of one side of the drive mounting seat 4 are provided with a pressure drive rod 6, and one end of the pressure drive rod 6 is fixedly connected to the top position of the installation slide rail 3 with an extrusion slide seat 7, and the middle part of one side of the extrusion sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com