Manufacturing equipment for environment-friendly plastic hose

A plastic hose, environmentally friendly technology, used in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of pipelines that do not meet production requirements, plastic hose deformation, increase factory costs, etc., to reduce frequent The number of inspections, the effect of reducing heat, and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

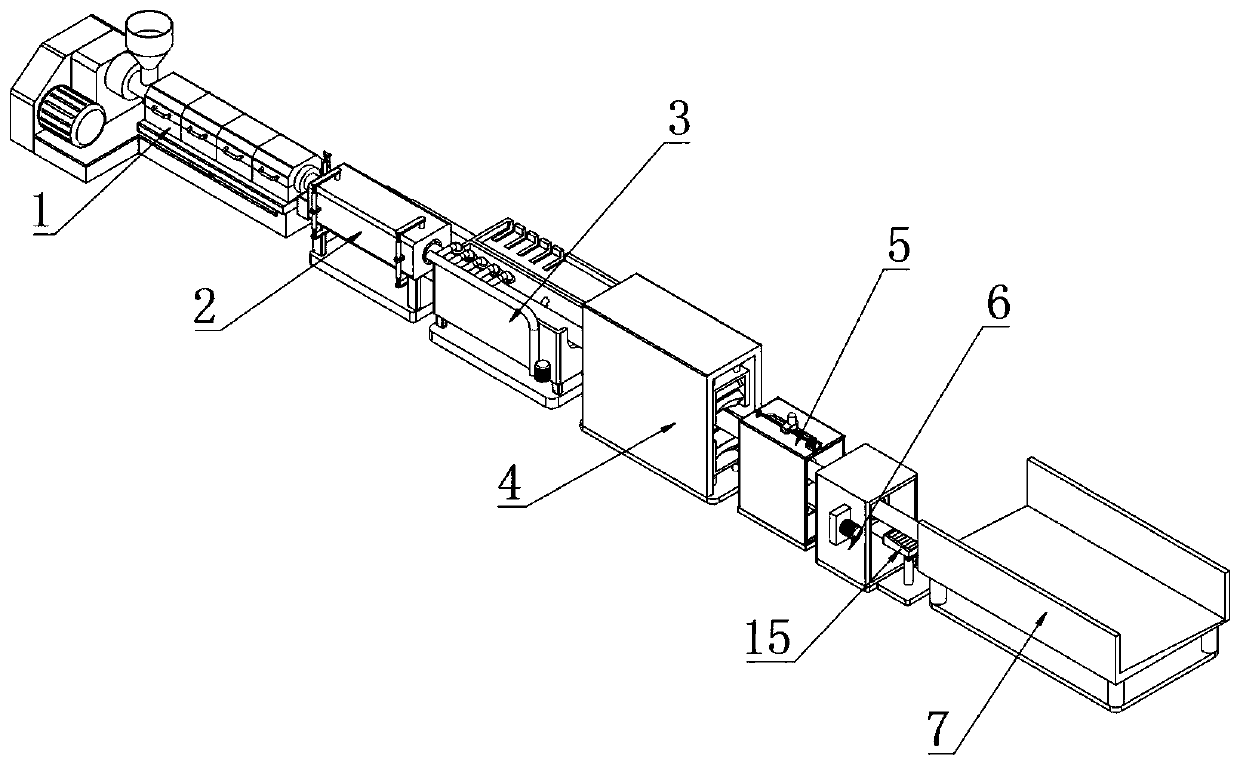

[0054] Example: such as Figure 1-12 As shown, the present invention provides a technical solution, an environmentally friendly plastic hose manufacturing equipment, including a pipe extruder 1, a plastic box 2 is connected to one side of the pipe extruder 1, and a quick Cooling box 3, one side of the rapid cooling box 3 is connected to a conveying box 4, one side of the conveying box 4 is connected to a grinding box 5, one side of the grinding box 5 is connected to a cutting box 6, and one side of the cutting box 6 is connected to a collection frame 7;

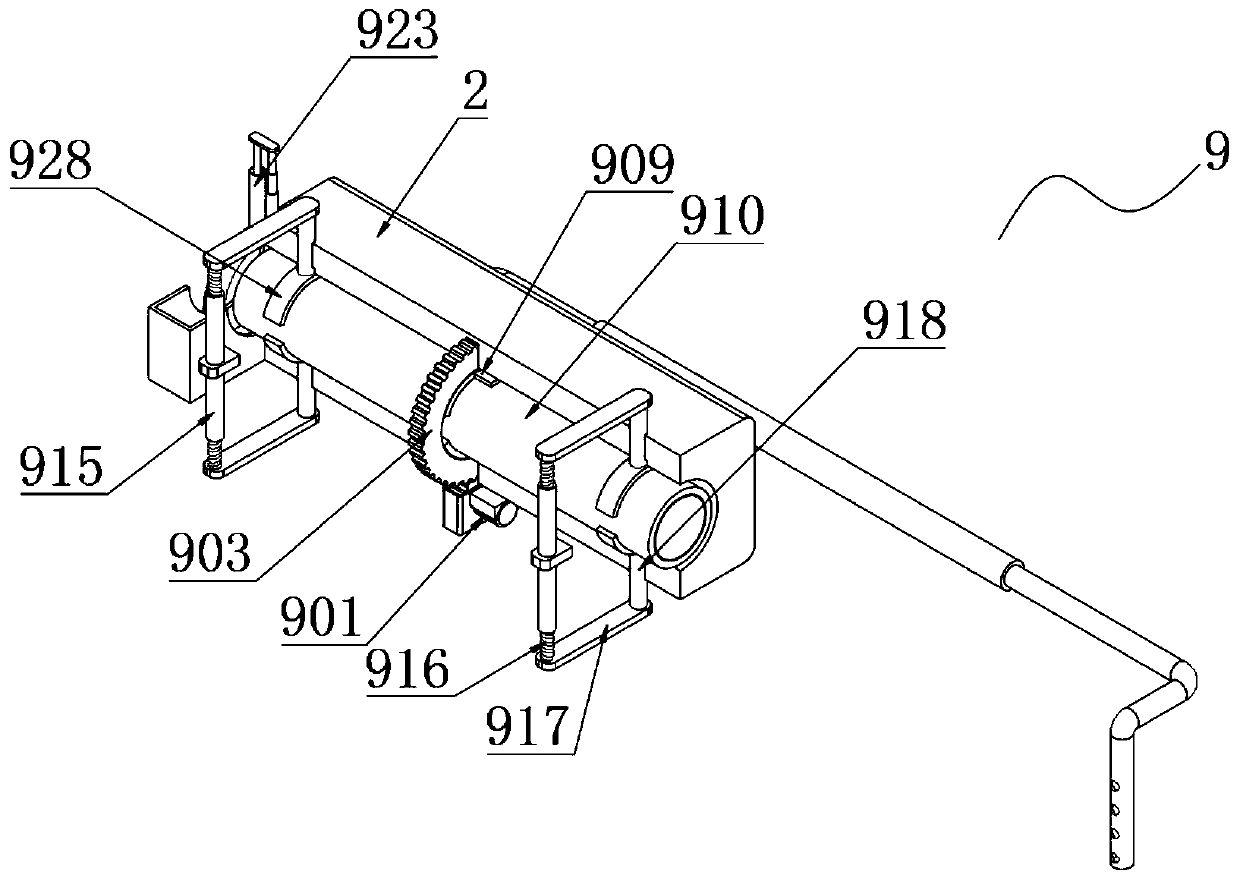

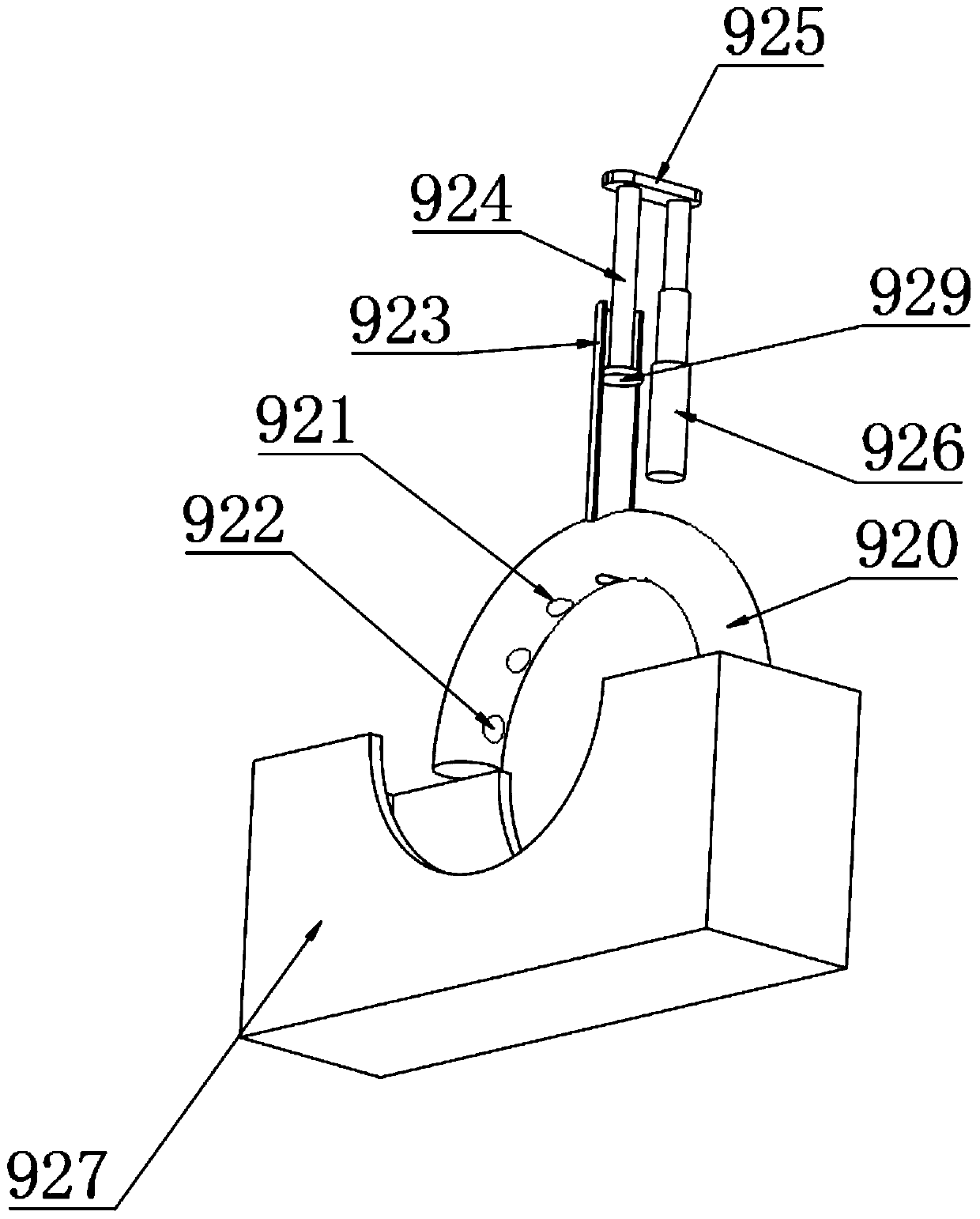

[0055] A quick shaping lubrication assembly 9 is installed inside the shaping box 2. The quick shaping lubrication assembly 9 includes a rotating motor 901, a driving gear 902, a driven gear ring 903, a clamping slot 904, a clamping column 905, a connecting spring 906, a driving arc plate 907, Driving groove 908, driving rectangular plate 909, shaping cylinder 910, rubber cylinder 911, rotation limit plate 912, rotation limit gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com