Pipe conveying equipment not prone to falling

A technology for conveying equipment and pipes, applied in the field of pipe conveying equipment, can solve the problems affecting the safety and reliability of conveying, pipe misalignment or offset, damage to the chain plate motor, etc. the risk of falling, the effect of reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

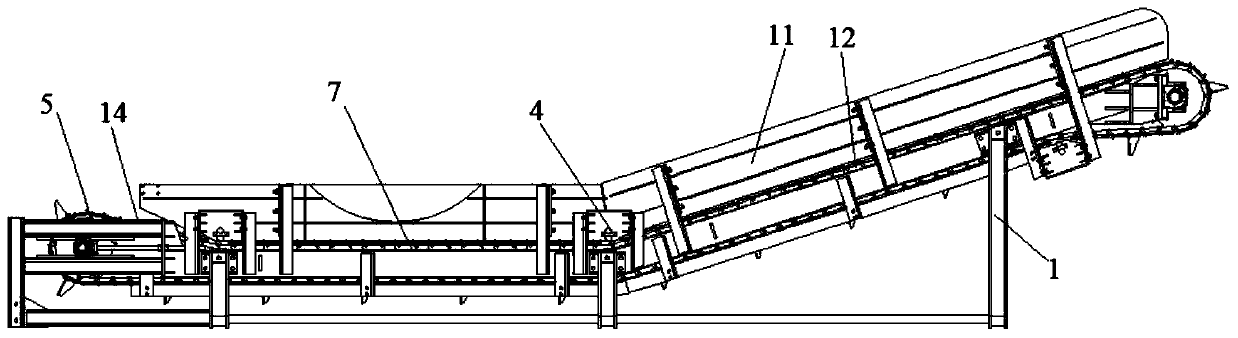

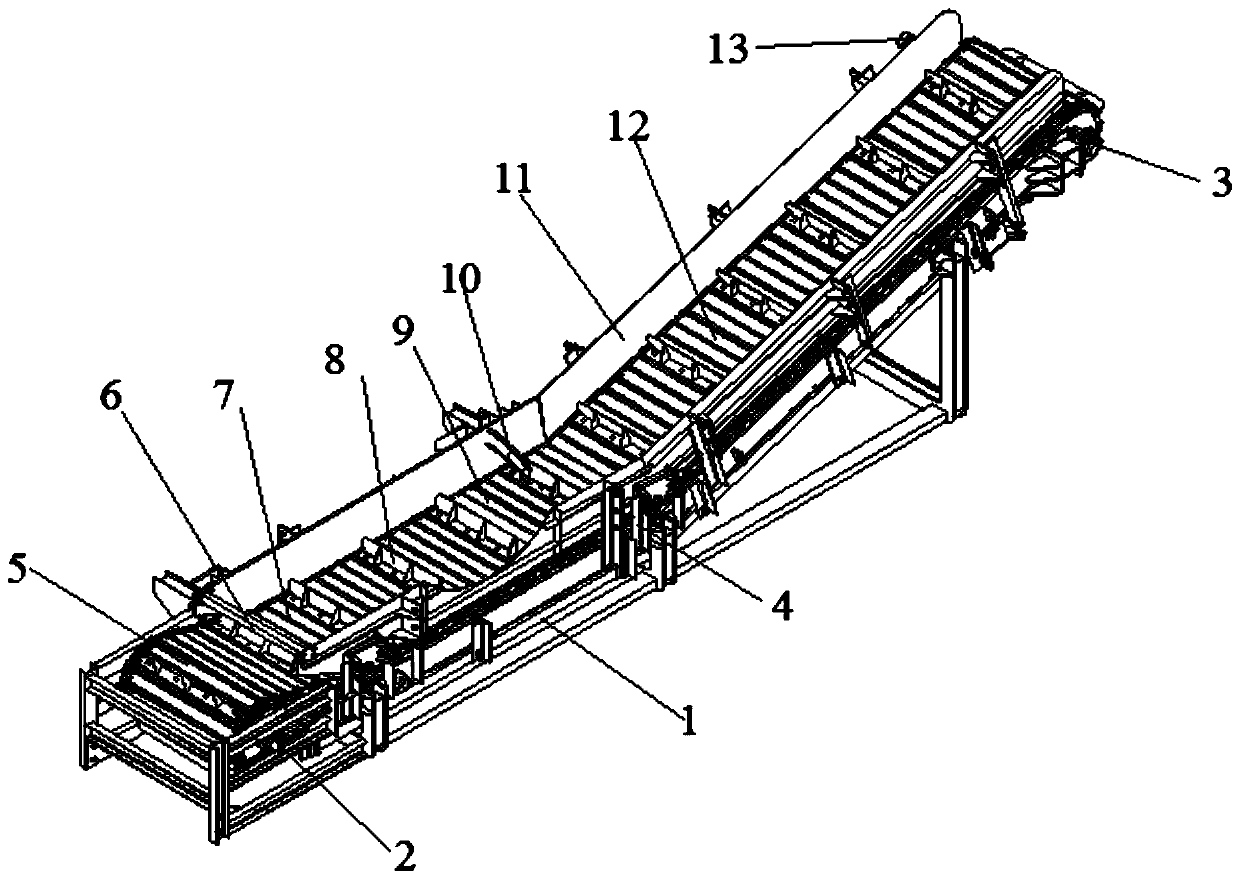

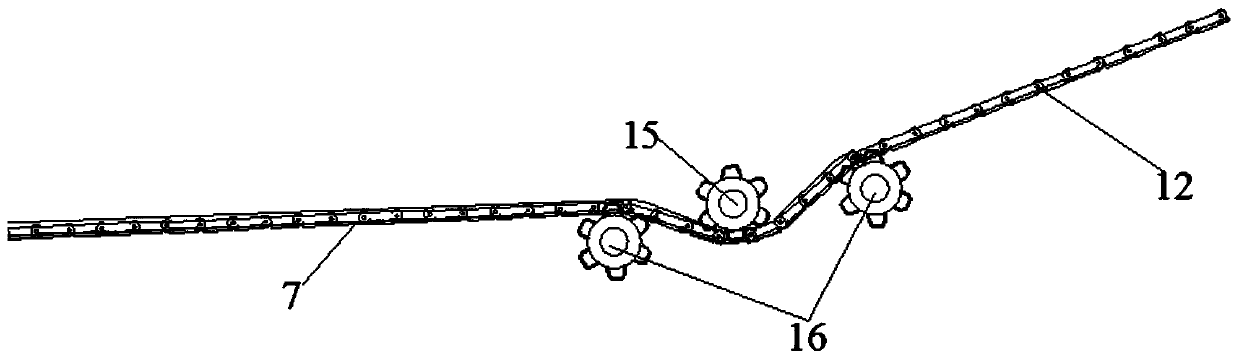

[0023] see Figures 1 to 5 , in an embodiment of the present invention, a pipe conveying equipment that is not easy to fall includes a frame 1, a driven sprocket 2, a driving sprocket 3, a conveying chain plate assembly 7 and a limit baffle 11, wherein the One side of the frame is provided with the driven sprocket, the other side of the frame is provided with the driving sprocket, and the driving sprocket is located obliquely above the driven sprocket, and the driven sprocket is arranged on the other side of the frame. Between the movable sprocket 2 and the driving sprocket 3, the conveying chain plate assembly is wound, and the two sides of the conveying chain plate assembly are provided with the limit baffles fixed on the frame, which is characterized in that It includes at least one set of auxiliary sprocket assemblies and at least one set of material receiving buffer mechanism 10, wherein each set of auxiliary sprocket assemblies is arranged at a position where pipes are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com