A kind of synthetic method of disperse blue 54

A synthesis method and technology of disperse blue, applied in chemical instruments and methods, anthracene dyes, organic dyes, etc., can solve the problems of unbalanced dinitroanthraquinone, excess dinitroanthraquinone, etc., and achieve easy access to raw materials and production The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

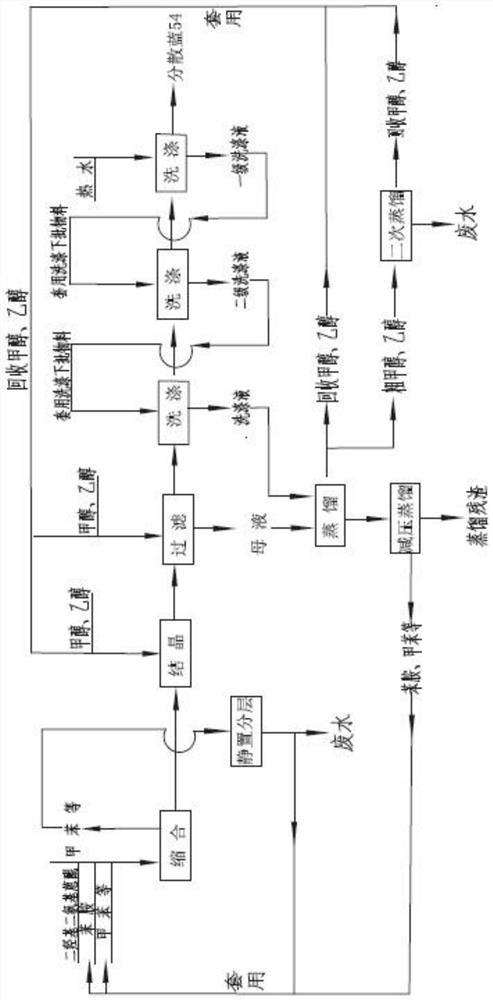

Image

Examples

Embodiment 1

[0062] The present embodiment provides a kind of synthetic method of disperse blue 54, comprises the steps:

[0063] a. add the mixed solution of 100 milliliters of aniline and 400 milliliters of toluene in reaction vessel;

[0064] b. Start stirring, add dihydroxy dinitroanthraquinone in 1-2 hours, keep the molar ratio of dihydroxy dinitroanthraquinone to aniline at 1:4;

[0065] c. After adding, heat up to 100°C in 1-2 hours, then heat up to 125°C in 2-3 hours, and keep warm for 6 hours;

[0066] d. During the heating and heat preservation process, collect the organic solvent fraction, let it stand for stratification, let off the water layer, and recycle the organic solvent for mechanical use;

[0067] e. Cool down to 70°C;

[0068] f. After the above condensation reaction, the mixture of dihydroxy dinitroanthraquinone, aniline and toluene is cooled to 70°C and then put into a crystallization container, methanol is added as a crystallization solvent, and the temperature is...

Embodiment 2

[0075] The present embodiment provides a kind of synthetic method of disperse blue 54, comprises the steps:

[0076] A. add the mixed solution of 150 milliliters of aniline and 350 milliliters of xylenes in reaction vessel;

[0077] b. Watch the stirring, add dihydroxy dinitroanthraquinone in 1-2 hours, keep the molar ratio of aniline and dihydroxy dinitroanthraquinone to aniline at 1:6;

[0078] c. After adding, heat up to 105°C in 1-2 hours, then heat up to 140°C in 2-3 hours, and keep warm for 3 hours;

[0079] d. During the heating and heat preservation process, collect the organic solvent fraction, let it stand for stratification, let off the water layer, and recycle the organic solvent for mechanical use;

[0080] e. Cool down to 65°C;

[0081] f. Cool the mixture of dihydroxy dinitroanthraquinone, aniline and toluene after the above condensation reaction to 65° C. and put it into a crystallization container, add ethanol as a crystallization solvent, and keep warm for ...

Embodiment 3

[0088] The present embodiment provides a kind of synthetic method of disperse blue 54, comprises the steps:

[0089] a. add the mixed solution of 250 milliliters of aniline and 250 milliliters of ethylbenzene in reaction vessel;

[0090] b. Watch the stirring, add dihydroxy dinitroanthraquinone in 1-2 hours, keep the molar ratio of dihydroxy dinitroanthraquinone to aniline at 1:12;

[0091] c. After adding, heat up to 110°C in 1-2 hours, then heat up to 135°C in 2-3 hours, and keep warm for 4 hours;

[0092] d. During the heating and heat preservation process, collect the organic solvent fraction, let it stand for stratification, let off the water layer, and recycle the organic solvent for mechanical use;

[0093] e. Cool down to 60°C;

[0094] f. Cool the mixture of dihydroxy dinitroanthraquinone, aniline and toluene after the above condensation reaction to 60°C and put it into a crystallization container, add methanol as a crystallization solvent, and keep warm for 1 hour ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com