A kind of heat treatment method of corrosion-resistant al-mg series alloy

A heat treatment method and alloy technology are applied in the field of heat treatment of corrosion-resistant Al-Mg alloys, which can solve problems such as inability to meet the requirements at the same time, and achieve the effects of low residual stress, wide alloy range and large process window.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

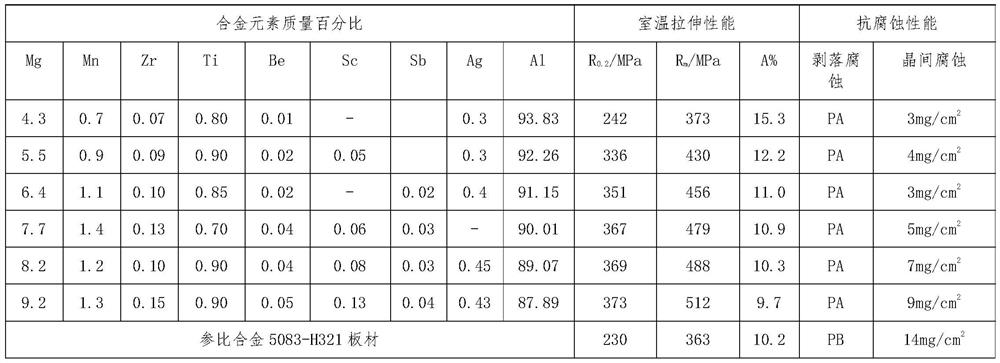

[0035] The flat ingots prepared according to the ingredients listed in Table 1 (the mass fraction of impurities Fe and Si should not exceed 0.4%), wherein Al, Mg, and Ag are added in the form of pure Al, pure Mg, and pure Ag, and Mn, Sc, Zr, Sb, Be and 0.03-0.10% Ti added for the first time are all added in the form of master alloy, and the slab ingot is obtained after smelting and casting.

[0036] The obtained flat ingots were homogenized at 500 °C, kept for 24 hours, and then air-cooled; the homogenized flat ingots were milled, and then heated to 400 °C to start rolling, and rolled with large deformation. Leave 20% deformation.

[0037] The plate is subjected to cold rolling treatment with a total deformation of 15%. The deformation amount of the pass is adjusted according to the rolling conditions. The deformed products are put into an annealing furnace for stabilization treatment. Double-stage heating is adopted. , and then cooled to 290 ~ 310 ℃, kept for 4 hours, and ai...

Embodiment 2

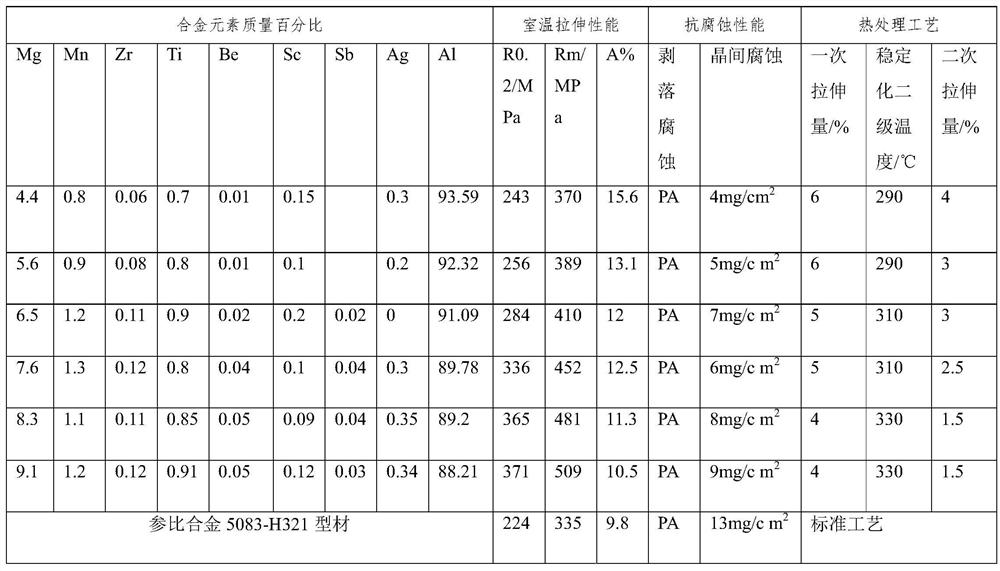

[0043] The round ingots prepared according to the components listed in Table 2 (the mass fraction of impurities Fe and Si should not exceed 0.4%), wherein Al, Mg, and Ag are added in the form of pure Al, pure Mg, and pure Ag, and Mn, Sc, Zr, Sb, Be and 0.03-0.10% Ti added for the first time are all added in the form of master alloy, and round ingots are obtained after smelting and casting.

[0044] The obtained flat ingot was homogenized at 500°C, kept for 24 hours, and then air-cooled; the homogenized flat ingot was milled, and then heated to 430°C to start extrusion, with an extrusion ratio of 9 to 30.

[0045]The profiles with different Mg contents are cold-stretched by 1% to 6%, and then the profiles are stabilized and heated in stages. The primary heating temperature is 380°C, and the temperature is kept for 0.5h; Heat preservation for 2 to 6 hours, and air-cooled.

[0046] The stabilized product is subjected to cryogenic treatment, and the liquid nitrogen cooling temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com