Prefabricated foundation pit for additionally installing elevator and construction method

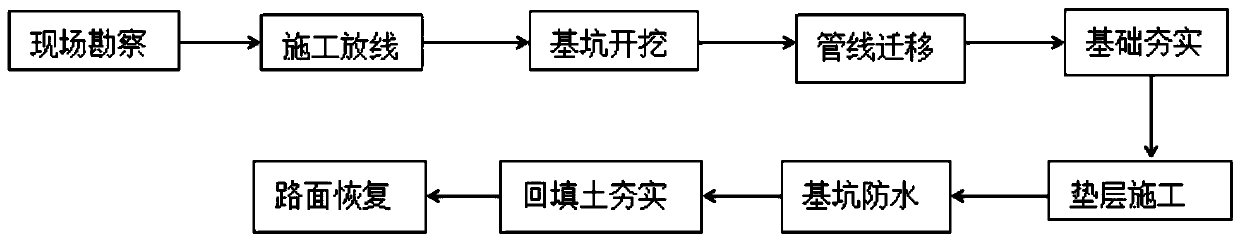

A construction method and technology for foundation pits, which are applied in basic structure engineering, excavation, protection devices, etc., can solve the problems of affecting the construction quality of the bottom pit, long construction period, heavy workload, etc., to facilitate quality control, save construction time, The effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

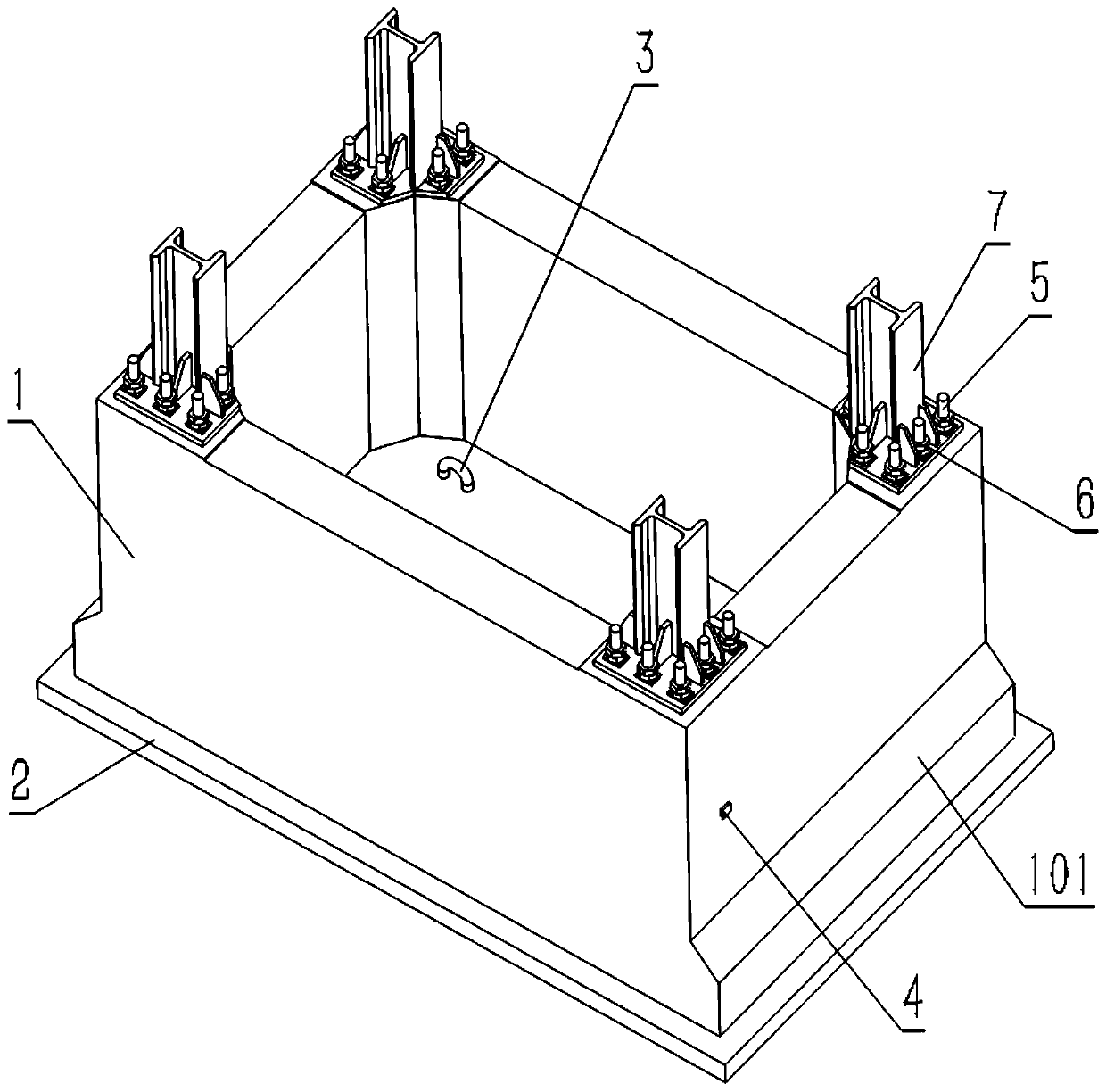

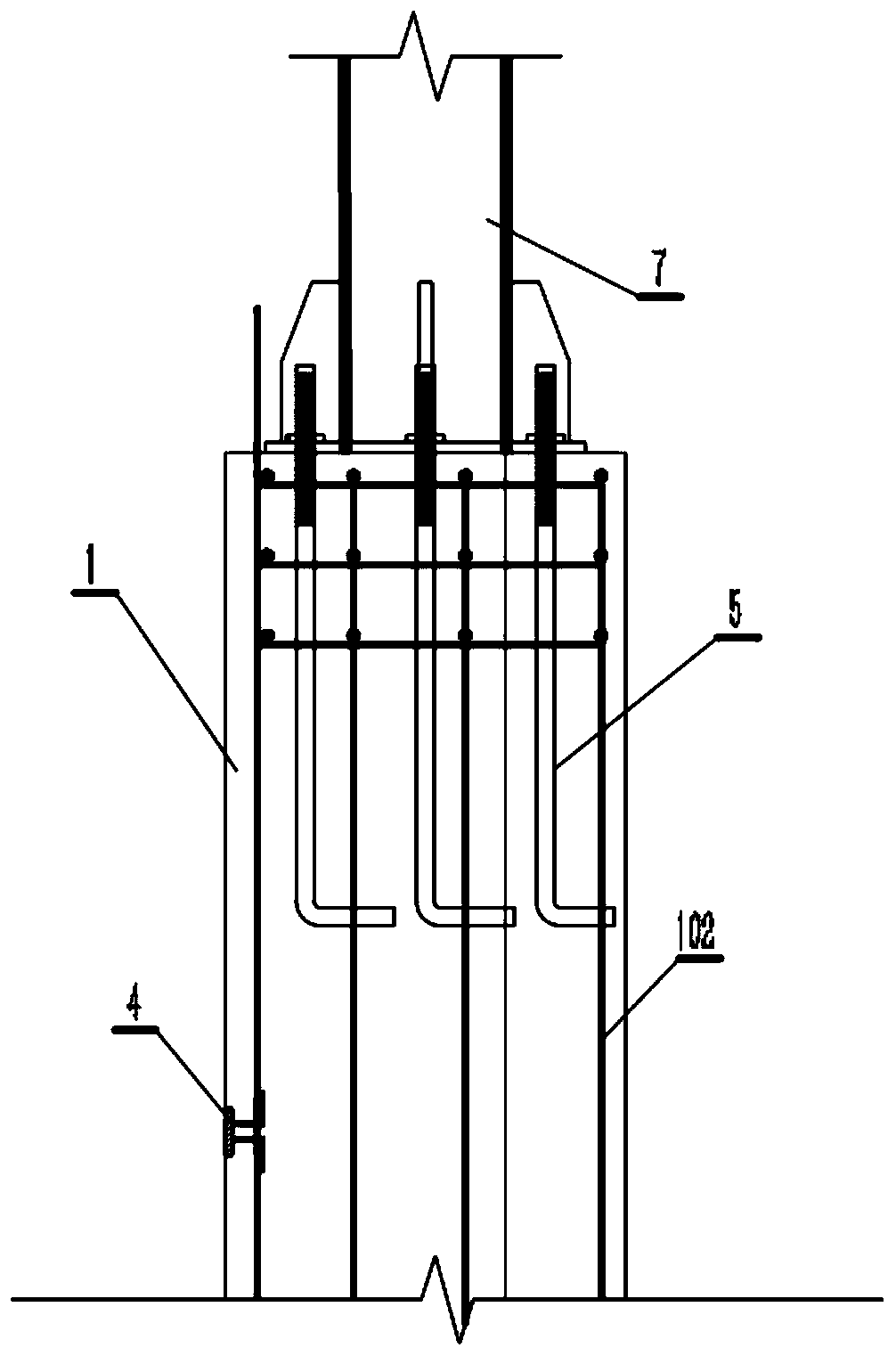

[0022] Such as Figure 1 to Figure 3 As shown, a kind of elevator prefabricated foundation pit of the present invention adopts the technical scheme that comprises foundation pit main body 1, and described foundation pit main body 1 is a rectangular reinforced concrete structure and its interior is steel bar frame 102, so A slope surface 101 is provided on both sides of the main body of the foundation pit 1. The main body of the foundation pit 1 is placed on the concrete cushion 2 as a whole. The four corners of the bottom surface of the inner cavity of the main body of the foundation pit 1 are fixedly connected with suspension rings 3. The four corners of the upper part of the foundation pit main body 1 are fixedly connected with column foot anchors 5, and the part of the column foot anchor bolts 5 that is poured into the foundation pit main body 1 is fixedly connected to the steel frame 102. The hoistway column 7 is installed on the foot anchor bolt 5 and locked by the nut 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com