Test method for internal force of phc pile body based on optical fiber strain and optical fiber layout method

A technology of PHC pile and optical fiber strain, which is applied in the direction of foundation structure test, fiber optic/cable installation, foundation structure engineering, etc. It can solve the problem of fluctuations and stress-strain values that cannot well reflect the force and bearing performance of pipe piles. Optical fiber damage and other problems, to achieve the effect of reliable data and theoretical basis, clear and orderly test process, and simple calculation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment provides a method for testing the internal force of a PHC pile body based on optical fiber strain, and the test method includes the following steps:

[0054] Step 1, preparation stage: select a number of PHC piles, number each of the PHC piles, and record the corresponding PHC pile test parameters; determine the preset location of each of the PHC piles and the piling sequence of the PHC piles; Selection and preparation of optical fibers, fiber optic sensors and fiber optic strain analyzers;

[0055] Step 2, pre-buried piling stage: laying distributed optical fiber sensors on the PHC piles, and driving the PHC piles into corresponding preset locations;

[0056] Step 3, measurement stage: Utilize the optical fiber strain analyzer to test the loading and unloading of the PHC pile, the test time under each level of load is selected after the displacement observation and judgment are stable, and the next level of load can be added (unloaded) after the acquisi...

Embodiment 2

[0080]This embodiment provides a method for laying optical fibers in Embodiment 1. The optical fibers are laid up and down along the pipe body of the PHC pile in a cross-symmetrical manner, and the laying method is as follows:

[0081] (1) Grooving on the surface: When the PHC pile is prefabricated, use a cutting machine to symmetrically cut a wiring groove with a width of 3mm and a depth of 3mm, and clean it for use; the wiring groove with a square cross-section is filled with epoxy resin glue , which can ensure that the optical fiber is evenly stressed;

[0082] (2) Wiring glue filling: pre-stretch the optical fiber and fix it in the wiring trough and make the optical fiber close to the bottom of the wiring trough, and backfill the prepared epoxy resin into the groove ; Use a hot air gun to trim and level off the epoxy resin glue. After 12 hours, the epoxy resin glue can be moved to lay the other side after the epoxy resin glue is completely cured; avoid the optical fiber is...

Embodiment 3

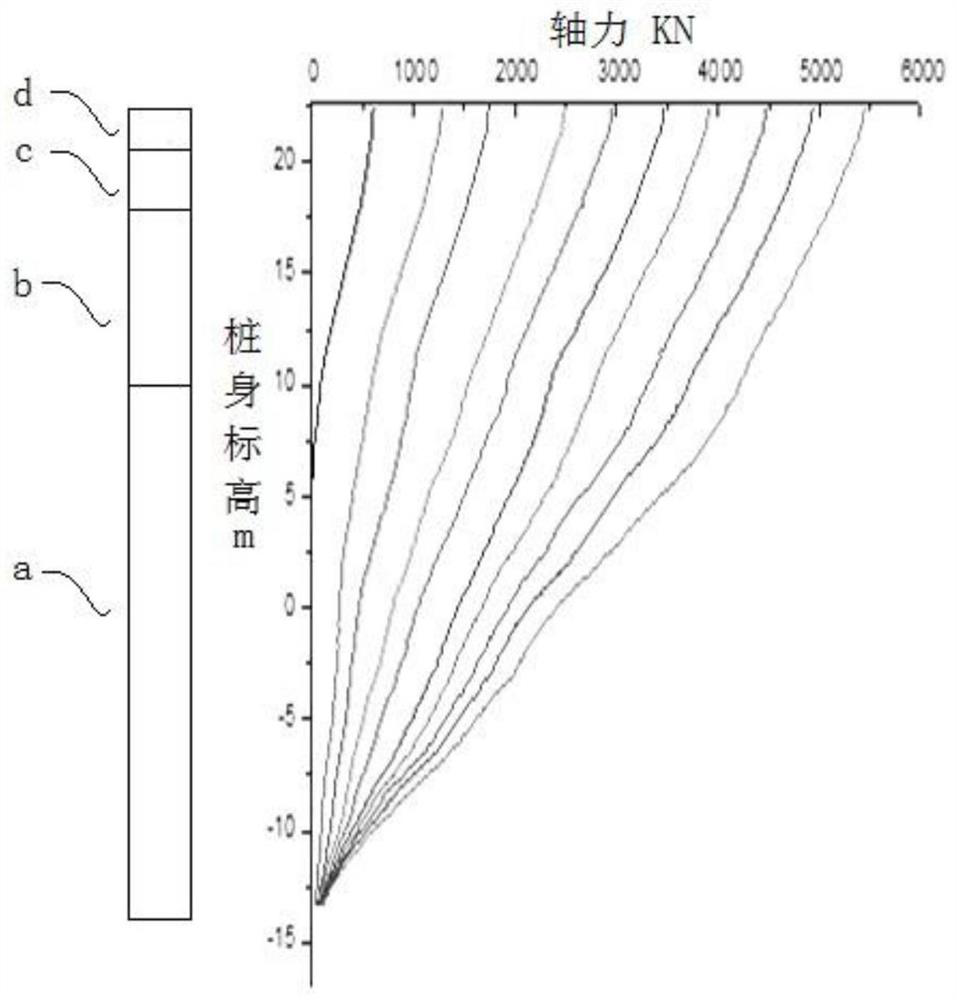

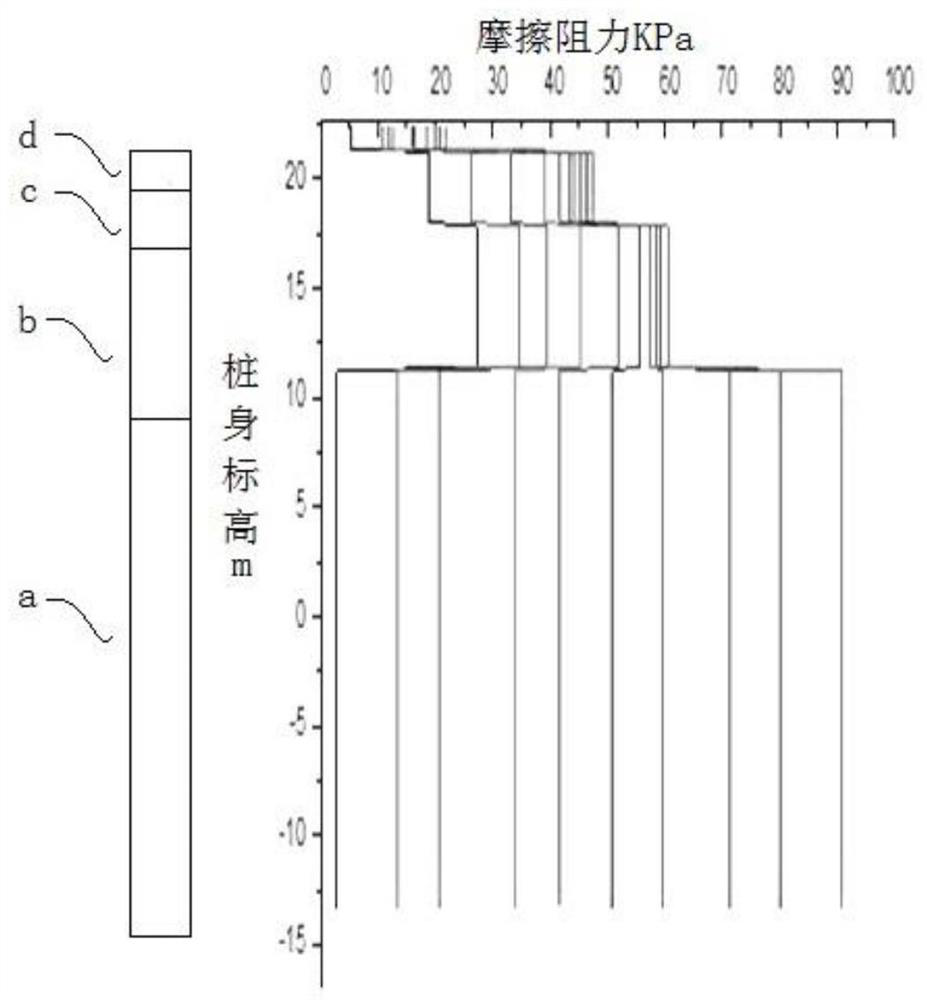

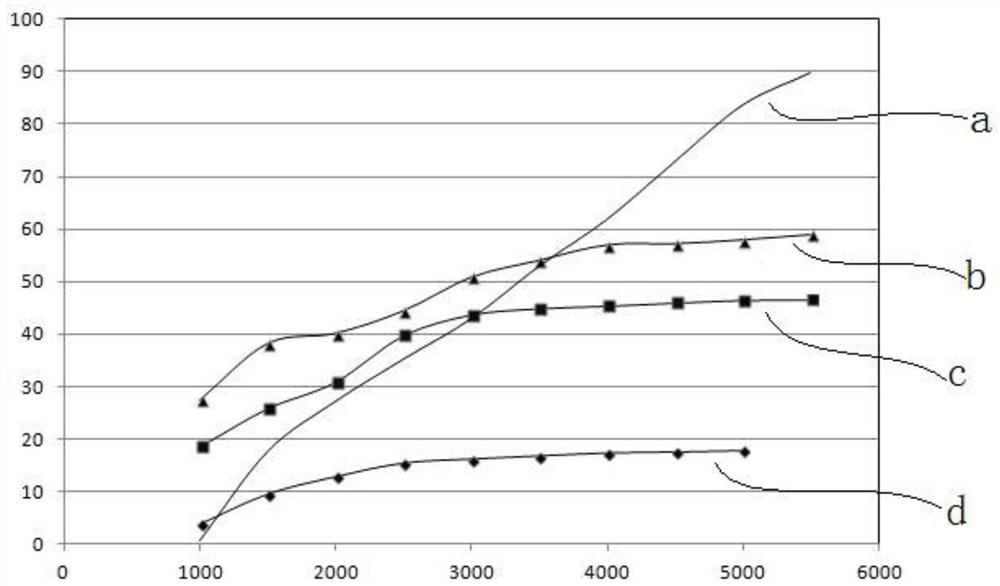

[0090] This embodiment provides a specific testing method.

[0091] The PHC piles are six, two groups of Φ600mmPHC pipe piles have 3 pieces (times) for compression test, and two groups of Φ600mmPHC pipe piles have 3 pieces (times) for horizontal test, totaling 6 pieces (times).

[0092] Test pile numbers are SZ1-1 # , SZ1-2 # , SZ1-3 # , SZ3-1 # , SZ3-2 # , SZ3-3 # , each test pile is spliced by upper pile, middle pile and lower pile. The upper pile is 13m, the middle pile is 11m, the lower pile is 14m, the pile diameter is 600mm, and the wall thickness is 110mm. The specific parameters of the pile body are shown in the table 1:

[0093] Table 1: Pile body parameters of the PHC pile

[0094] Chainage pile diameter pile length Steel strength pile top elevation Burial depth Effective test length SZ1-1 #

600mm 38m C80 23.79m 37.50m 35.80m SZ1-2 #

600mm 38m C80 23.80m 37.50m 35.80m SZ1-3 #

600mm 38m C80 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com