Concrete prefabricated wall board and construction method thereof

A technology of prefabricated wall panels and concrete, applied in the direction of walls, building components, building materials, etc., can solve the problems of high energy consumption, decreased thermal insulation performance, inability to meet the concept of life, etc., to improve comfort, improve sound insulation performance, and reduce energy. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

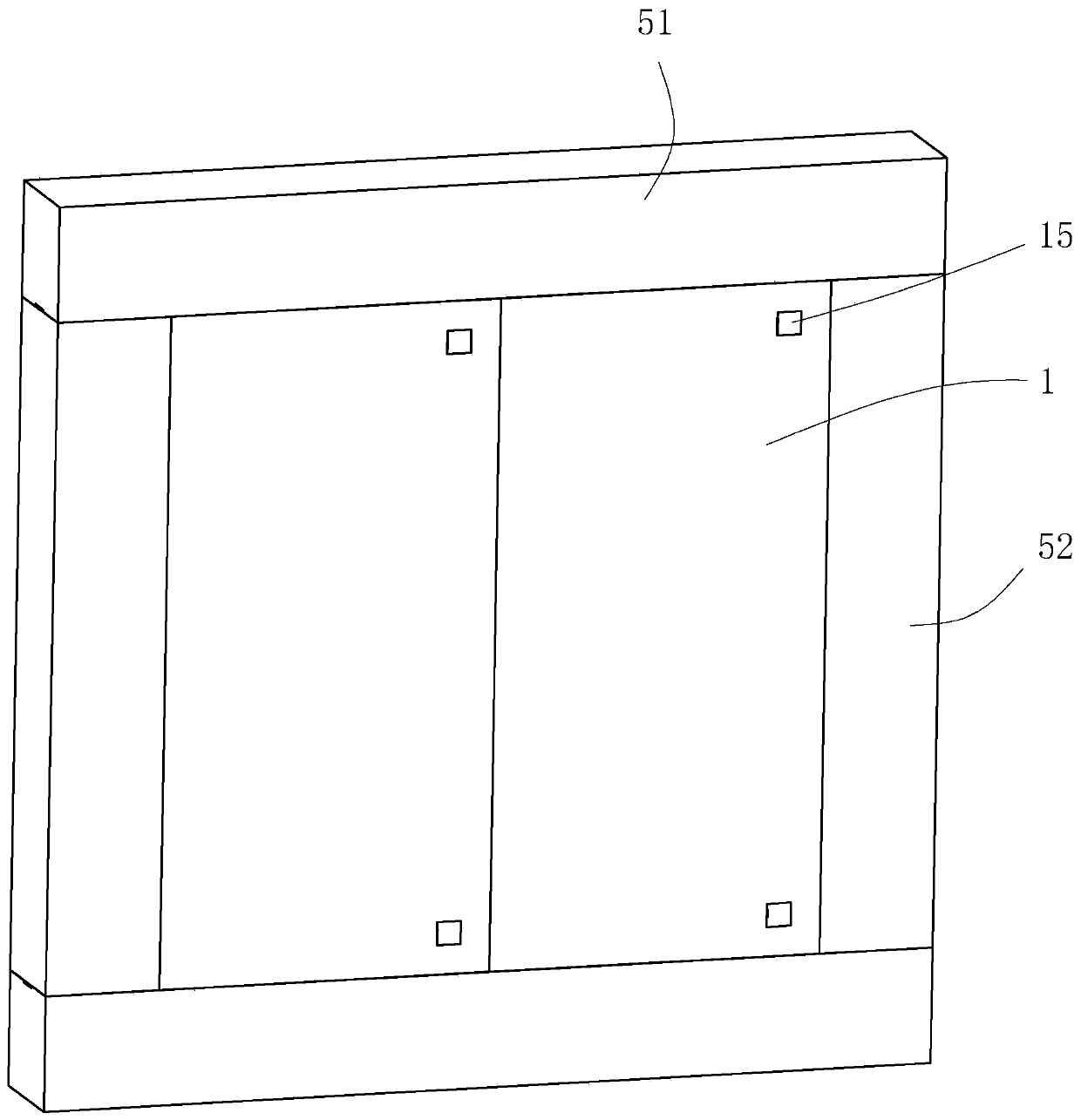

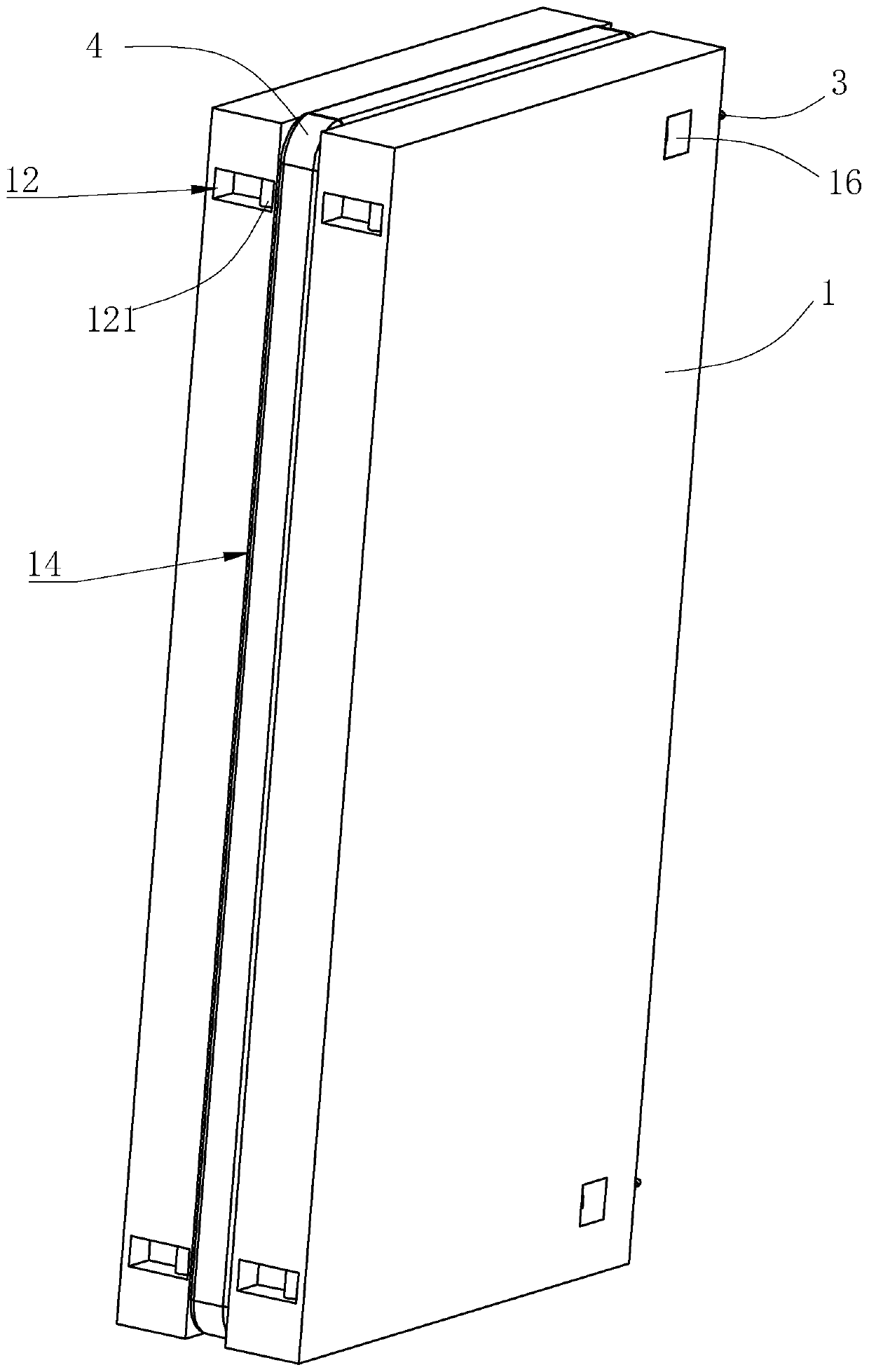

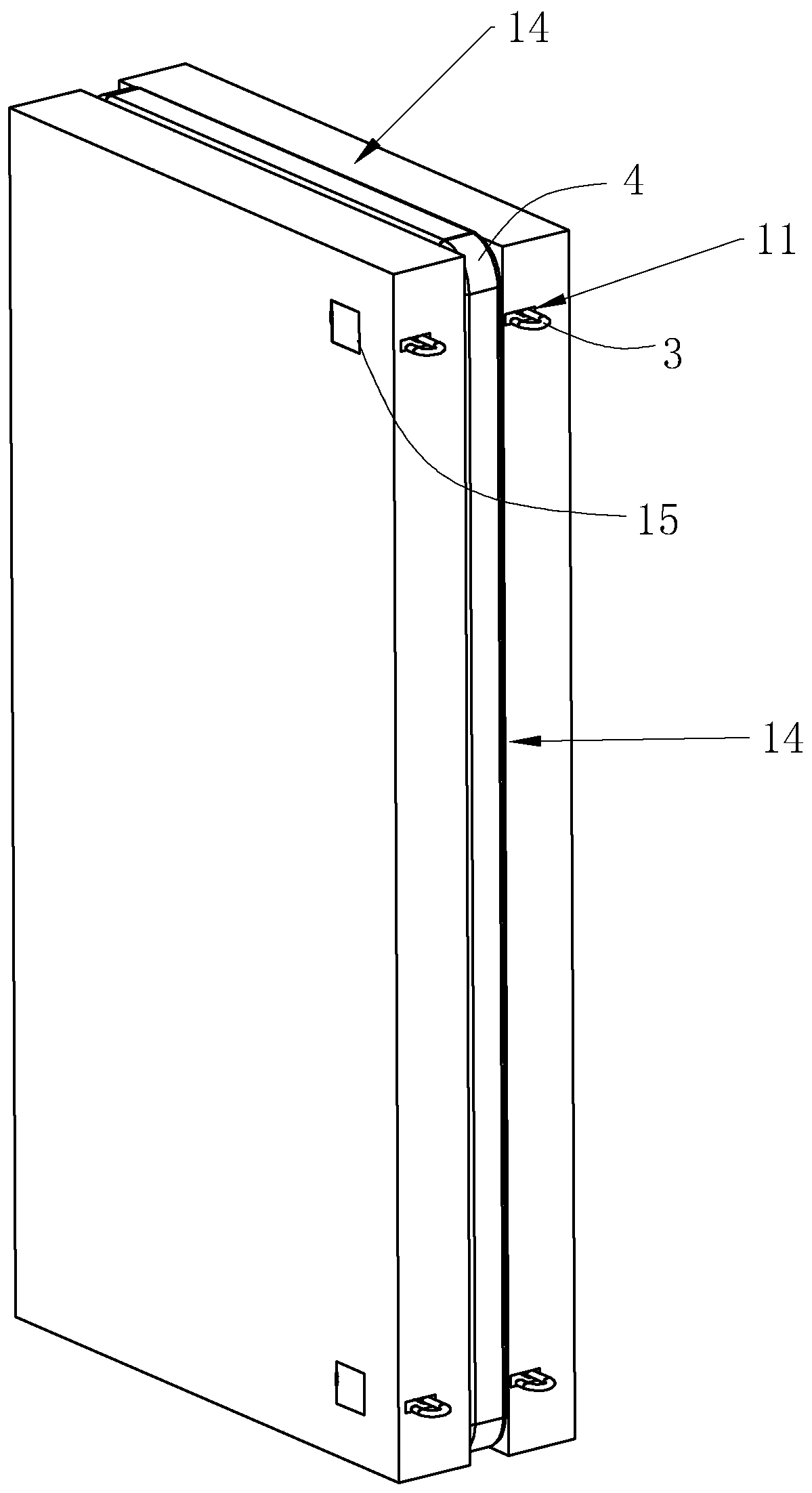

[0041] Such as Figure 1 to Figure 2 As shown, a concrete prefabricated wall panel disclosed by the present invention includes a vertically arranged rectangular wall panel body 1, and the wall panel body 1 includes a larger front, back, vertical left and right sides and Horizontal upper and lower bottom surfaces. The wall panel body 1 is connected with the column body 52 of the building to block the space between adjacent beams and columns, and can be used as an exterior wall or an indoor partition wall.

[0042] Such as Figure 2 to Figure 3 As shown, the left and right sides of the wallboard body 1 and the upper and lower grounds are jointly provided with an annular groove 14 communicating with each other, and an annular air bag 4 is embedded in the annular groove 14, and the annular air bag 4 is connected with an inflation tube 41, and the inflation tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com