Data-driven accurate regulation and control method for urban central heating system

A centralized heating and data-driven technology, applied in heating systems, heating methods, household heating, etc., can solve problems such as high control costs, low utilization efficiency, and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

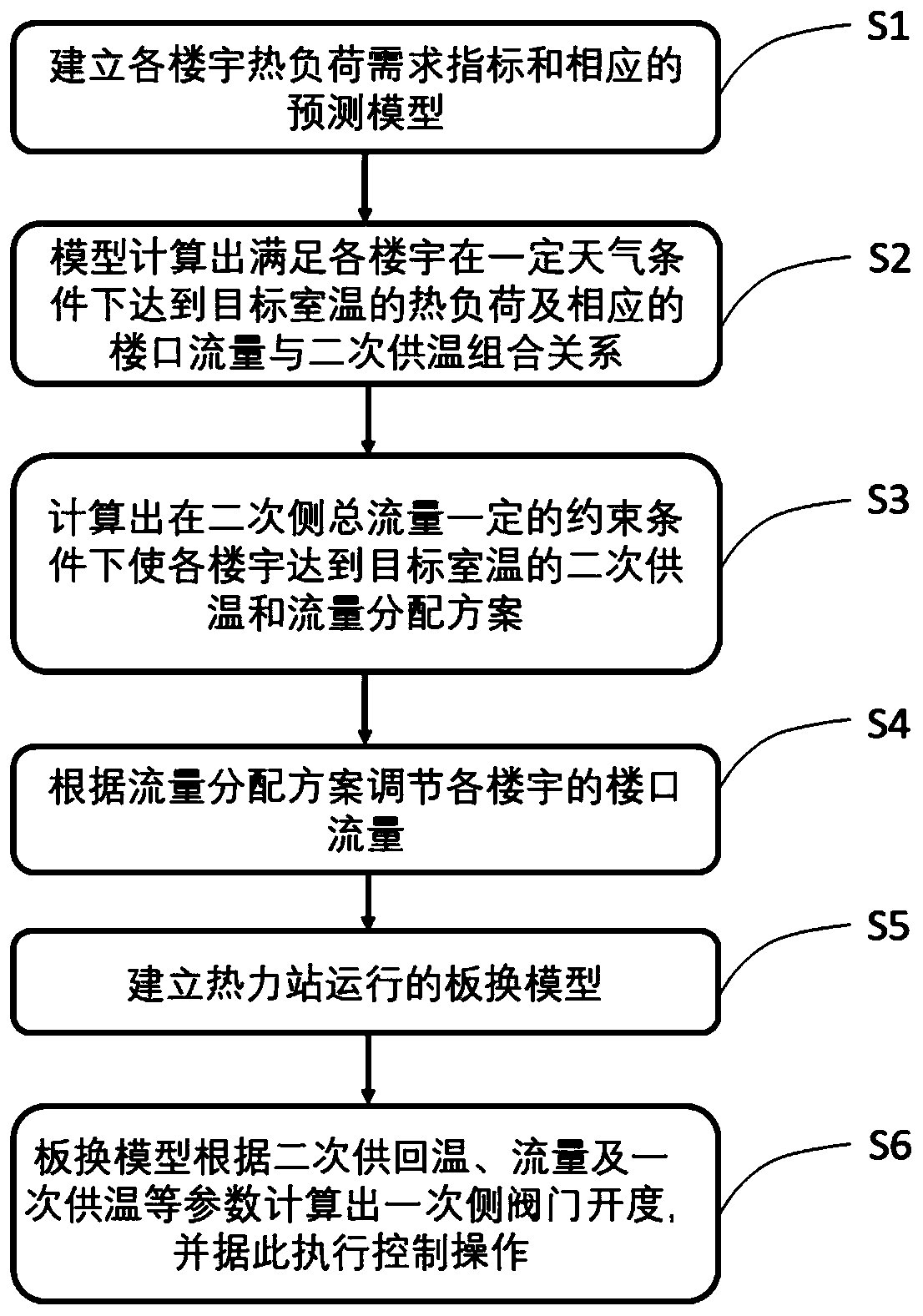

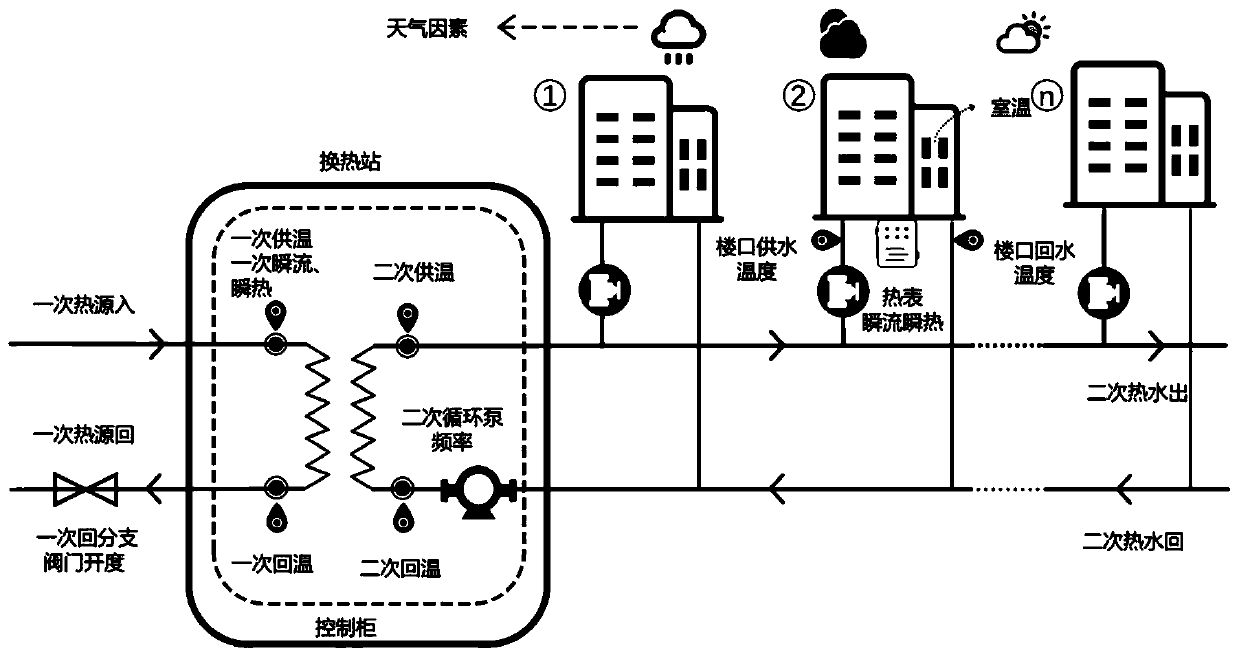

[0099] combine figure 1 , figure 2 and image 3 , the present invention relates to a data-driven precise control method for urban central heating systems, specifically comprising the following steps:

[0100] Step S1, establishing heat load demand indexes and corresponding prediction models for each building;

[0101] Step S2, using the predictive model to calculate the heat load that meets the target room temperature of each building under certain weather conditions and the corresponding combination relationship between the building flow and the secondary side heating;

[0102] Step S3, calculating the secondary side supply and flow distribution scheme for each building to reach the target room temperature under certain constraint conditions of the secondary side total flow;

[0103] Step S4, adjusting the entrance flow of each building according to the flow distribution plan;

[0104] Step S5, establishing a plate replacement model for the operation of the thermal stati...

Embodiment 2

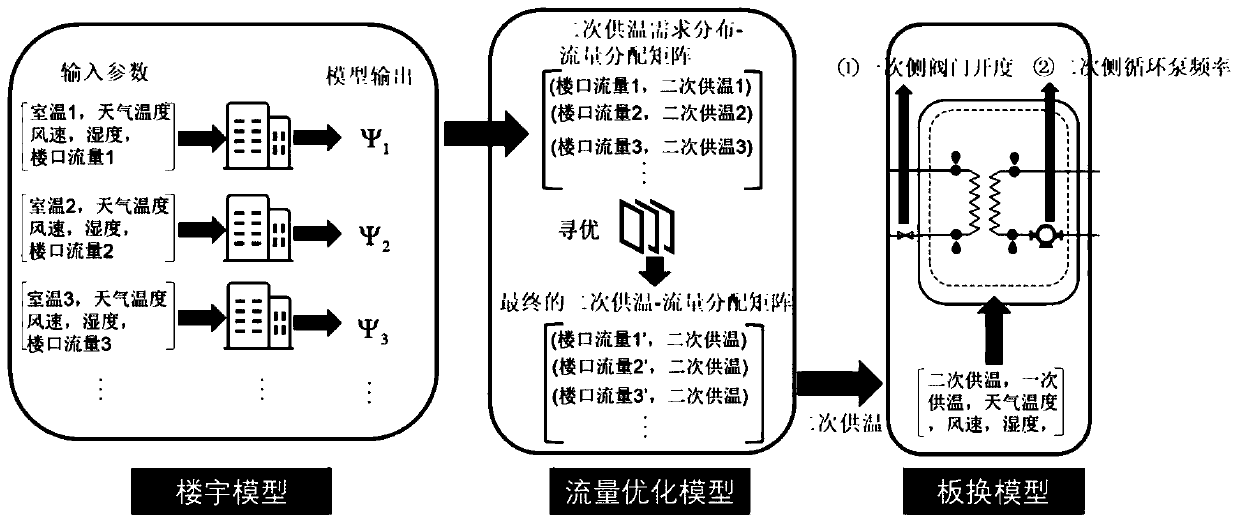

[0141] On the basis of Example 1, combined with image 3 , this embodiment 2 provides a central heating system on-demand precise control system, including:

[0142] A model building module, used for building a building heat load demand forecasting model;

[0143] The optimization module of flow at the floor opening and the temperature supply at the secondary side, that is, image 3 The flow optimization model in is used to calculate the secondary side supply and the corresponding floor flow distribution scheme to make the building reach the target room temperature;

[0144] The thermal station primary side valve operation adjustment model building module is used to obtain the thermal station plate exchange rate obtained through training according to the current primary side temperature supply, secondary side return temperature, secondary side flow rate, and the secondary side temperature supply to be achieved. The model calculates the opening degree of the primary side valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com