Ventilation and turbulence type hot air drying room and working method thereof

A kind of flow, hot air technology, applied in drying, dryer, lighting and heating equipment and other directions, can solve the problems of affecting the quality of fruit and vegetable processing, increasing user production costs, uneven drying of materials, etc., to achieve good application prospects, airflow The effect of improved retention and increased airflow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with accompanying drawing, and its content is explanation of the present invention rather than limitation:

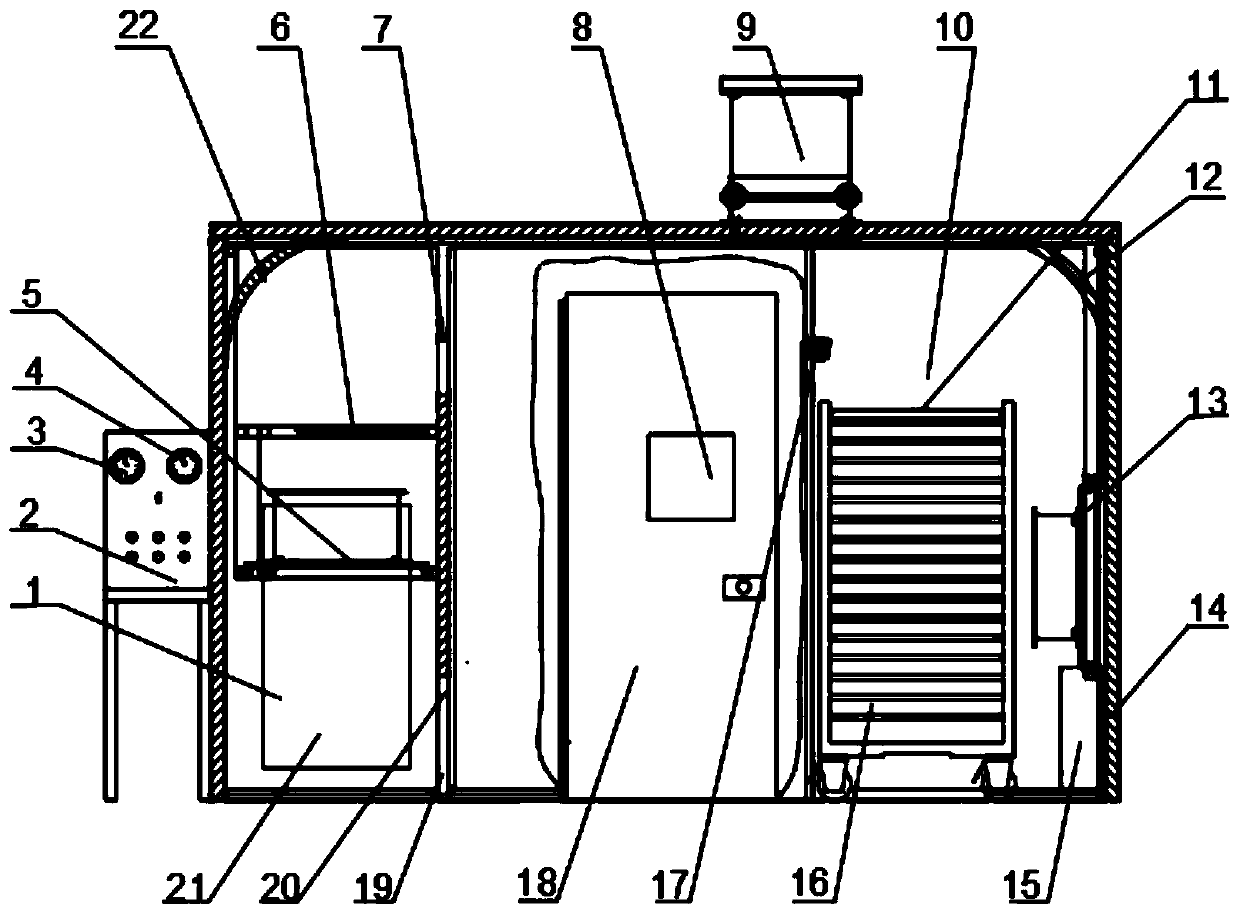

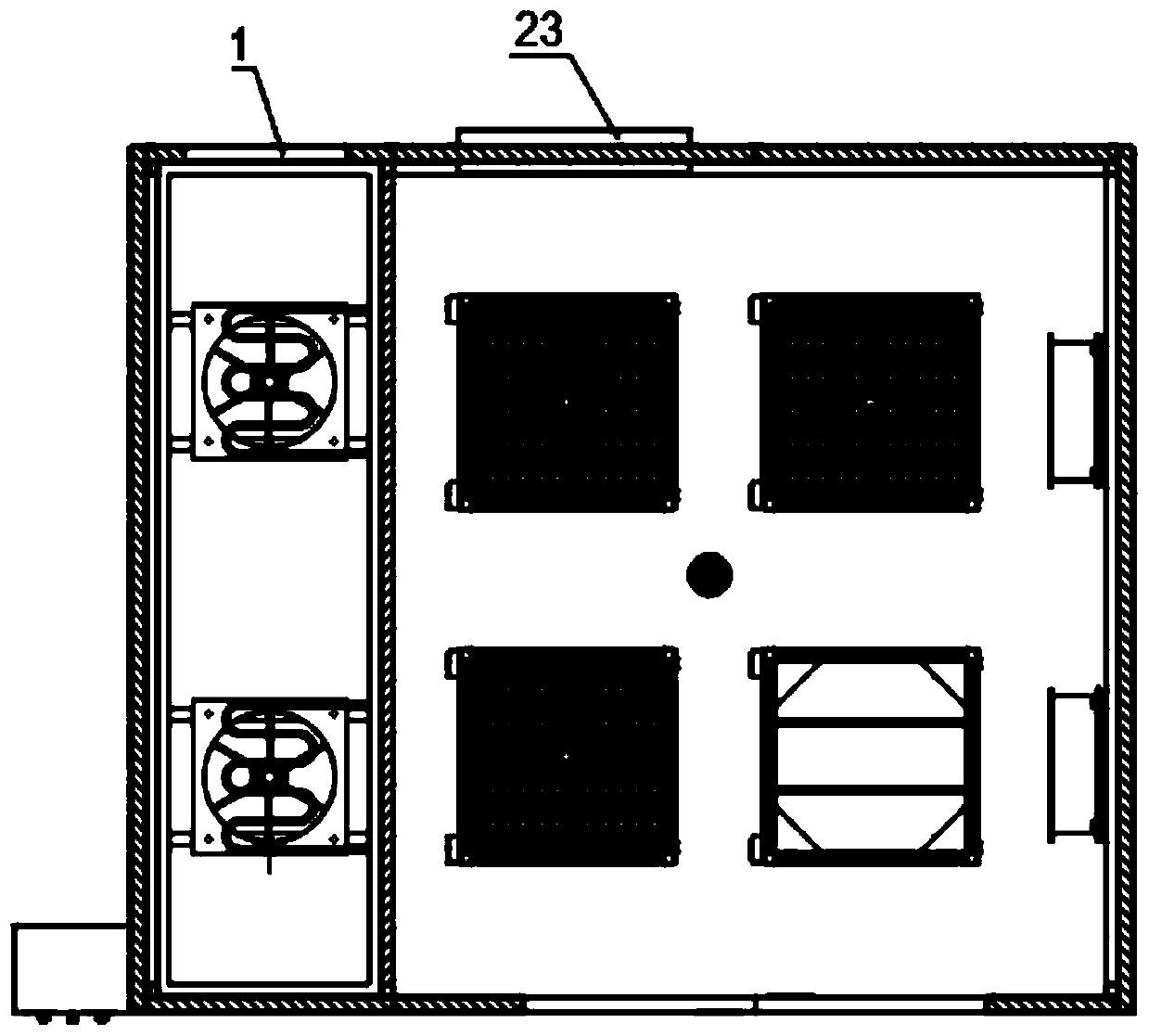

[0036] Such as figure 1 , figure 2 , is the air guiding and disturbing type hot air drying room of the present invention, including a control system and a drying room body. The drying room body is a closed space formed by a heat insulating wall 14 and a roof. layer composite structure, or an insulation layer can be added outside the basic structure. A door 18 is provided on the thermal insulation wall 14 , preferably, an observation window 8 is provided on the door 18 . The interior of the drying room body is divided into a drying chamber 10 and a heating chamber 21 by a middle partition 20 , the upper part of the middle partition 20 is provided with a drying chamber air inlet 7 , and the lower part of the middle partition 20 is provided with a drying chamber return air outlet 19 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com