Induction motor rotor broken bar fault detection method based on stator current absolute phase

A technology of absolute phase and broken rotor bars, applied in the field of fault diagnosis, which can solve problems such as poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

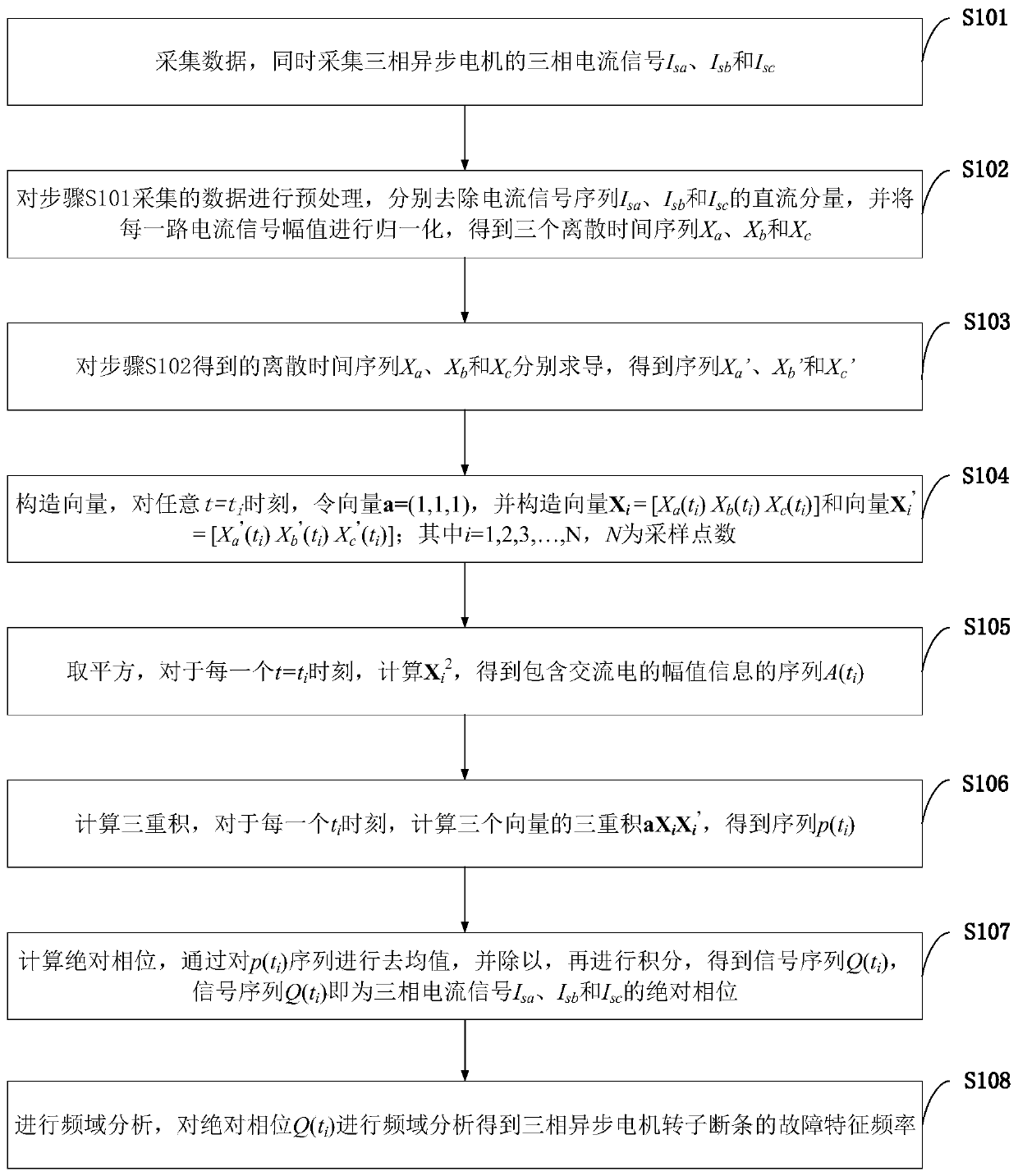

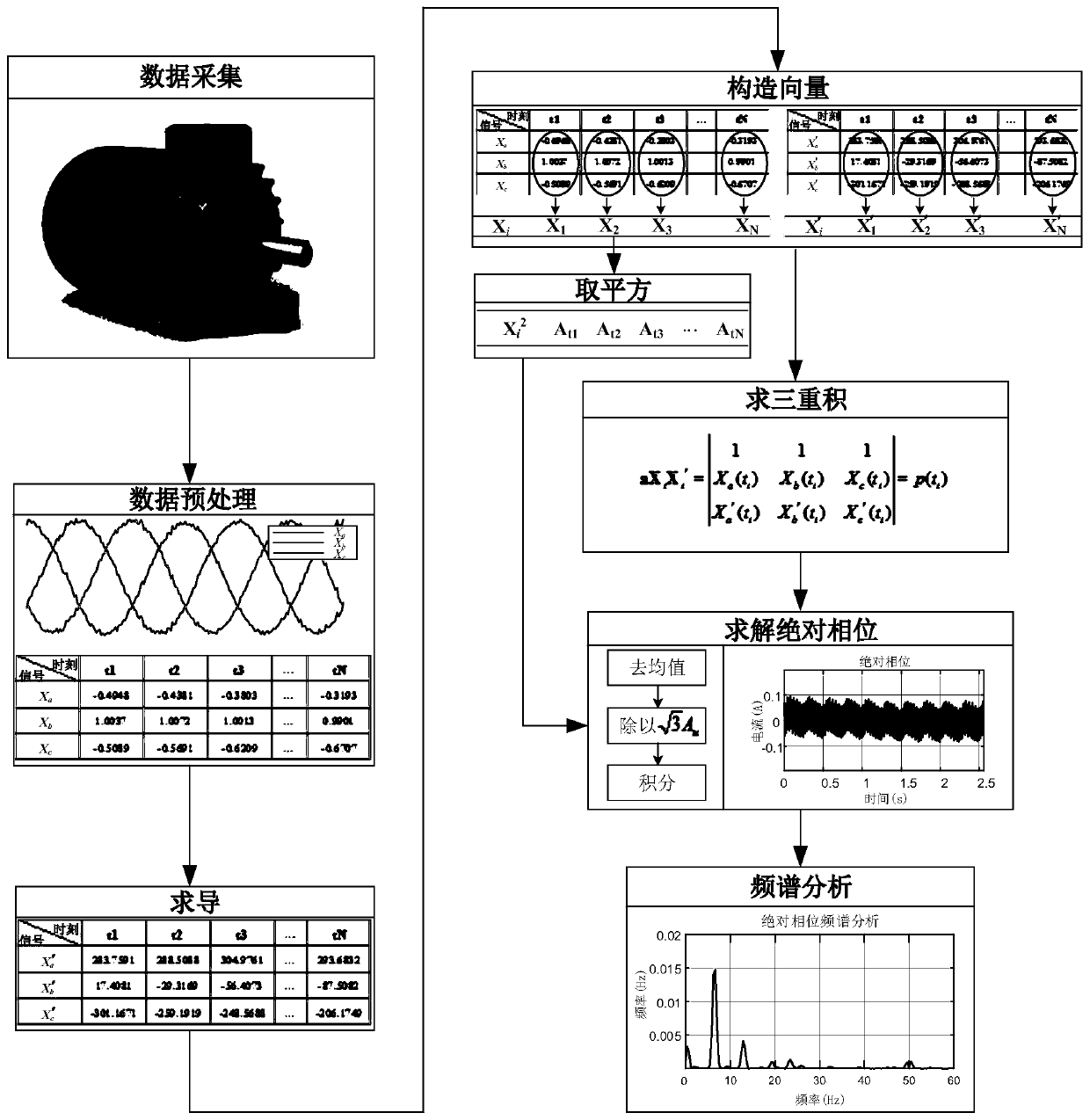

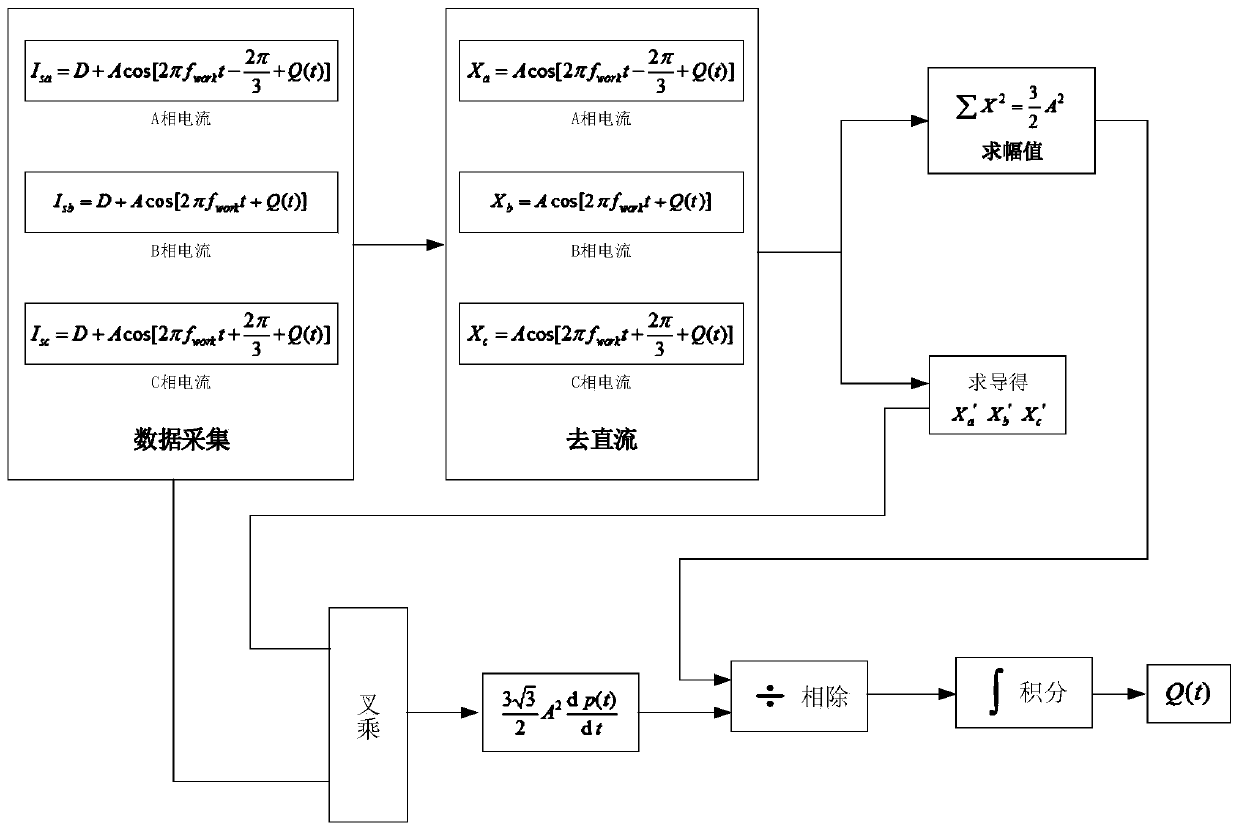

[0137] A method for detecting a broken bar fault of an induction motor rotor based on the absolute phase of the stator current of the present invention, the steps of which are as follows:

[0138] 1) data acquisition, simultaneously gather the three-phase current signal I of the three-phase asynchronous motor sa , I sb and I sc :

[0139] 1.1) Connect the fault diagnosis system, three current sensors, and the data acquisition system.

[0140] 1.2) Set the sampling frequency and collect data of the three current signals at the same time.

[0141] 2) data preprocessing, respectively remove the current signal sequence I sa , I sb and I sc , and normalize the amplitude of each current signal to obtain three discrete time series X a 、X b and X c ;:

[0142] 2.1) Deaverage: remove the DC component contained in the collected current signal.

[0143] I m =I sm -mean(I sm )

[0144] Among them, mean(I) is the mean value of the calculated current sequence I, and m are a, b,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com