Preparation method of integrally prefabricated intermediate joint

An intermediate joint, prefabricated technology, applied in the manufacture of contact box/base, assembly/disassembly, and connection of contacts, etc., can solve the problem of the insulation of the intermediate joint body, which is prone to cracks, the single structure layer of the intermediate joint, and the reduction of the overall Mechanical properties and other issues, to achieve the effect of improving the mechanical properties of finishing, convenient preparation and fast production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

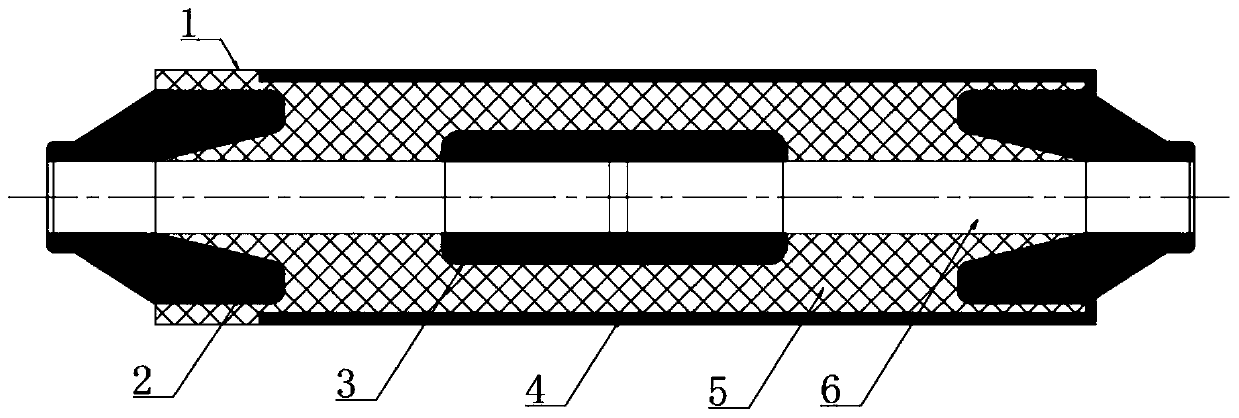

[0024] according to figure 1 The overall prefabricated intermediate joint shown includes an intermediate joint body 1. The intermediate joint body 1 includes a stress cone 2, a high voltage shield 3, an insulating outer shield 4 and an insulating filling layer 5. The axis of the intermediate joint body 1 A cable 6 is provided at both ends of the cable 6, and two stress cones 2 are arranged symmetrically. An insulating filling layer 5 is provided between the insulating outer shield 4 and the cable 6;

[0025] Further, the stress cone 2, the high-voltage shield 3, the insulating outer shield 4 and the insulating filling layer 5 are all made of semi-conductive liquid silicone rubber material, and the insulating filling layer 5 is provided with glass fibers;

[0026] A method for preparing an integral prefabricated intermediate joint, the specific operation steps are:

[0027] Step 1: Inject the mixed semi-conductive liquid silicone rubber into the stress cone 2 mold with a rubb...

Embodiment 2

[0033] according to figure 1 The overall prefabricated intermediate joint shown includes an intermediate joint body 1. The intermediate joint body 1 includes a stress cone 2, a high voltage shield 3, an insulating outer shield 4 and an insulating filling layer 5. The axis of the intermediate joint body 1 A cable 6 is provided at both ends of the cable 6, and two stress cones 2 are arranged symmetrically. An insulating filling layer 5 is provided between the insulating outer shield 4 and the cable 6;

[0034] Further, the stress cone 2, the high-voltage shield 3, the insulating outer shield 4 and the insulating filling layer 5 are all made of semi-conductive liquid silicone rubber material, and the insulating filling layer 5 is provided with glass fibers;

[0035] A method for preparing an integral prefabricated intermediate joint, the specific operation steps are:

[0036] Step 1: Inject the mixed semi-conductive liquid silicone rubber into the stress cone 2 mold with a rubb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com