Flexible waterproof sealing structure for underground direct-buried cable or optical cable through-wall and construction method

A flexible seal and cable technology, applied in the field of electrical engineering, can solve the problems of unfixed winding form, inability to form radial extrusion stress, and inability to form a sealed space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The flexible waterproof sealing structure and construction method for underground direct buried cables or optical cables passing through walls of the present invention will be described in detail below with reference to the embodiments and accompanying drawings.

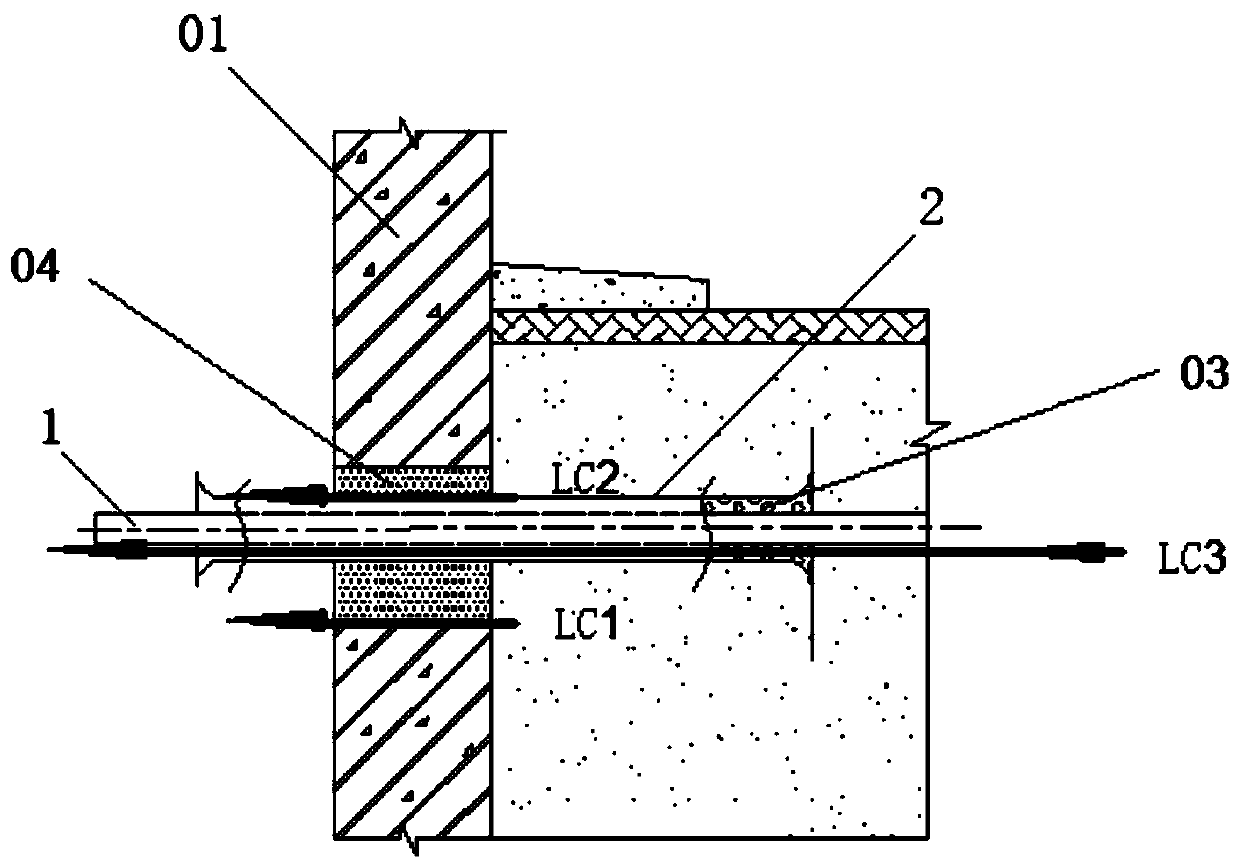

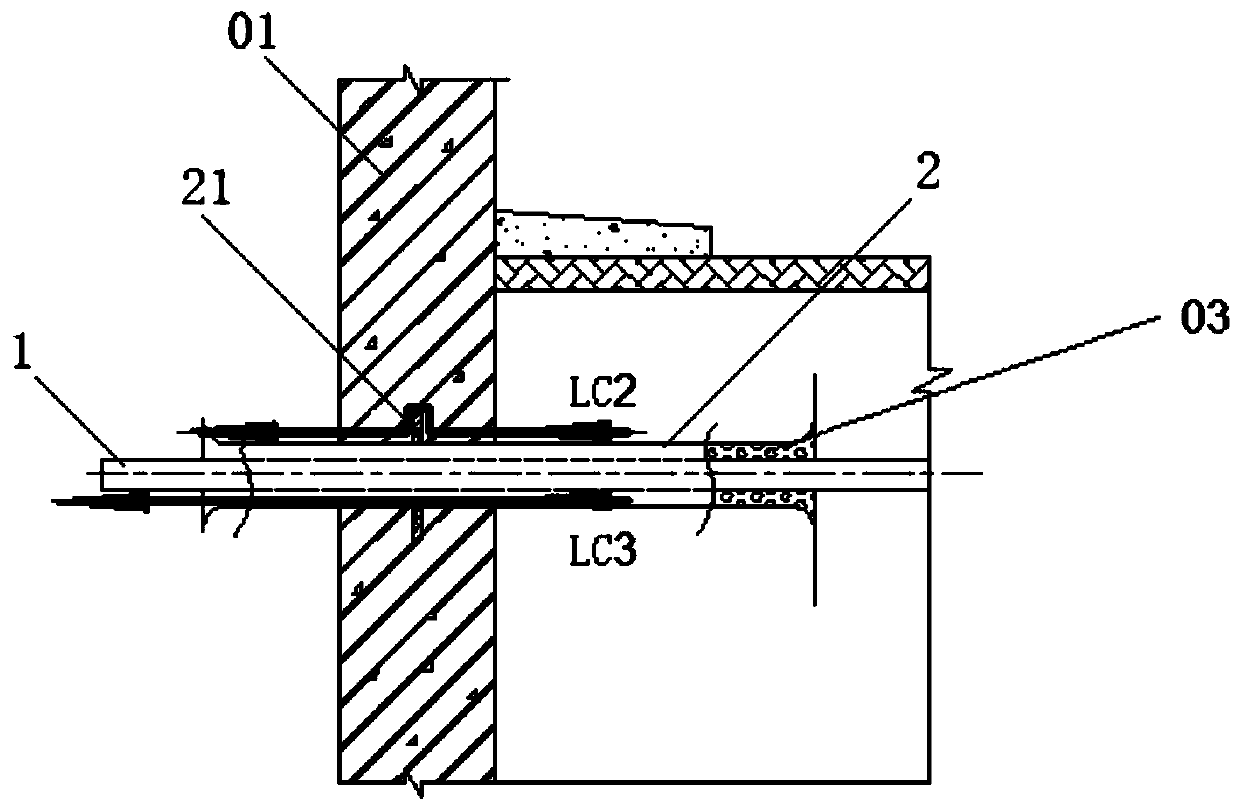

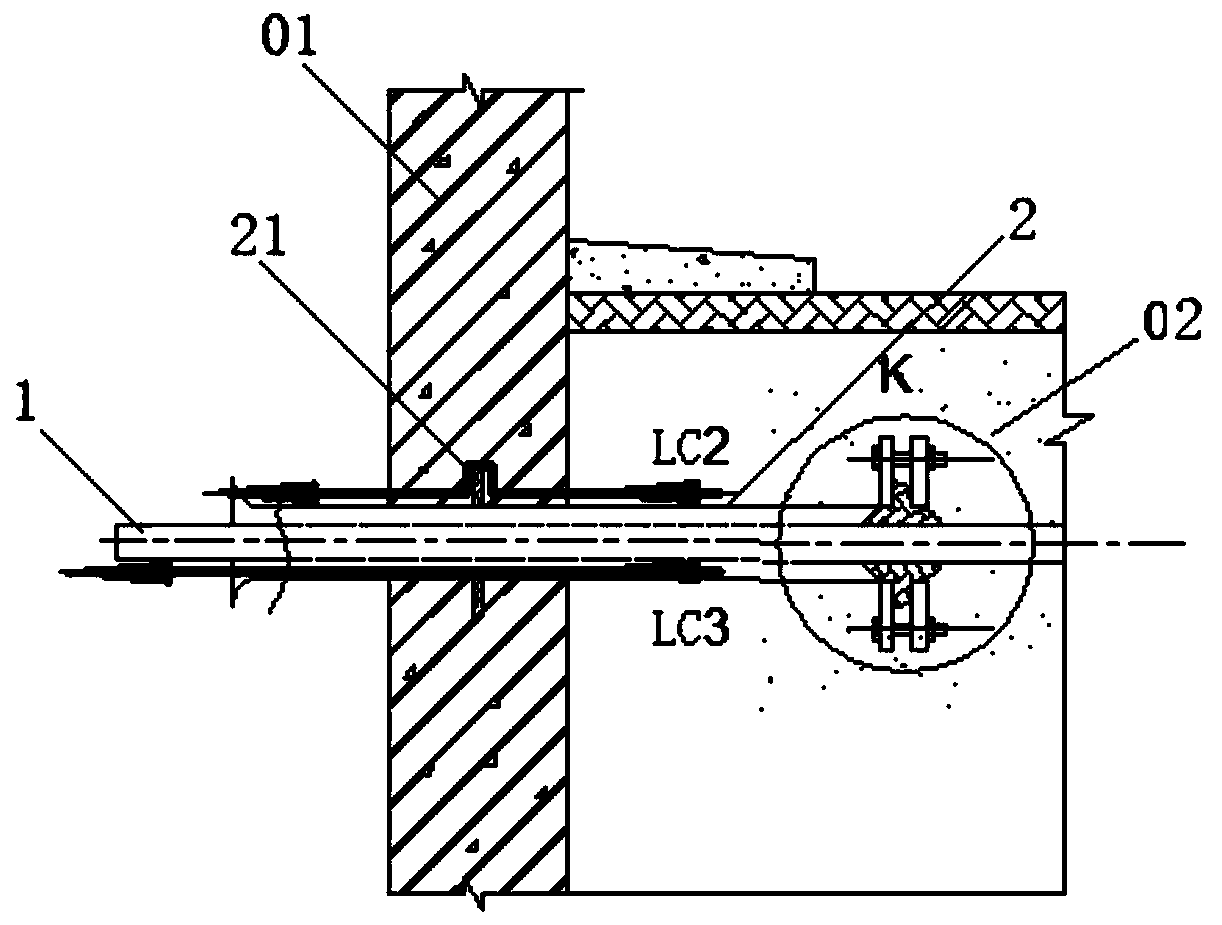

[0060] Figure 2A In the shown embodiment, the flexible waterproof sealing structure is used to seal the underground direct buried cable or optical cable 1 passing through the wall 01, and includes a wall-penetrating protection tube 2 and a flexible sealing assembly 3, and the wall-penetrating protection tube 2 is passed through In the reserved hole provided in the wall 01, the electric cable or optical cable 1 is inserted into the wall-through protection tube 2, and the flexible sealing component 3 is arranged at least on the Z2 side of the wall-through protection tube 2 facing the water, so as to seal the wall-through protection tube 2 The third leakage channel LC3 formed between the cable or optical cable 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com